A 6 inch grinder wheel is an indispensable accessory for any workshop, providing the power and precision needed for a wide range of tasks from sharpening tools to deburring metal. Choosing the right 6 inch grinding wheel can significantly impact the efficiency and quality of your work. With various materials, grits, and applications, understanding the differences is key to making an informed decision. This comprehensive guide reviews the top 5 6 inch grinder wheels on the market, helping you find the perfect match for your bench grinder and specific needs.

Quick Product Comparison

Our Top 5 6 Inch Grinder Wheel Reviews – Expert Tested & Recommended

1. 6 inch Bench Grinder Buffing and Polishing Wheel, Extra Thick, with 1/2-inch Arbor

This 6 inch bench grinder buffing and polishing wheel is designed for versatility and longevity. Its extra-thick, 70-ply construction ensures a larger surface area and prolonged service life, making it a reliable choice for various polishing tasks. The standard 1/2-inch arbor hole allows for easy installation on most common bench grinders.

💡 Related:

bench grinder grinding wheel

Key Features That Stand Out

- ✓ Extra Thick 70-Ply Design for extended durability and broader surface coverage.

- ✓ Universal 1/2-inch Arbor Hole ensures compatibility with most bench grinders.

- ✓ Concentric Sewn Circles provide consistent pressure and a smooth finish.

- ✓ Versatile Application suitable for wood, various metals (cast iron, brass, aluminum bronze), and stone.

Why We Recommend It

We recommend this buffing wheel for its superior build quality and adaptability. The extra thickness means you get more use out of it, and its ability to handle different materials makes it a highly practical tool for both professional workshops and home hobbyists looking for a high-quality polishing wheel for bench grinder.

Best For

This wheel is best for those who frequently undertake polishing and buffing tasks on a variety of materials, from softwoods to harder metals and stone, and require a durable, long-lasting solution.

Pros and Cons

Pros:

- Excellent durability due to 70-ply construction.

- Compatible with most standard bench grinders.

- Provides a superior, consistent polish across different materials.

- Thick design offers a larger working surface.

Cons:

- May require specific polishing compounds for optimal results.

- Not suitable for aggressive material removal, primarily for finishing.

Customer Reviews

Customer Review: Durable and with very little wear with use.

Customer Review: This buffing wheel holds up exceptionally well even after numerous projects. A great addition to my bench grinder.

2. CBN 6-inch Grinding Wheel, 320 Grit, with 1/2-inch Bore for High-Speed Steel Bench Grinders

For those working with high-speed steel (HSS) tools, the CBN 6-inch grinding wheel, 320 grit is a game-changer. Made from superior CBN (Cubic Boron Nitride) materials, this wheel is engineered for precision sharpening without deformation, ensuring your tools maintain a consistently sharp edge. Its 1/2-inch bore fits most standard bench grinders, offering convenient and fast sharpening.

Key Features That Stand Out

- ✓ Superior CBN Material prevents deformation and extends wheel life significantly.

- ✓ 320 Grit for Fine Sharpening provides a keen, precise edge on tools.

- ✓ Designed for High-Speed Steel making it perfect for woodworking and machining tools.

- ✓ Standard 6-inch Diameter with 1/2-inch Arbor for broad compatibility.

Why We Recommend It

This CBN wheel stands out for its specialized application and exceptional performance. It excels at sharpening high-speed steel tools, providing sharper edges faster and with less heat buildup than traditional wheels. It’s a premium investment for maintaining woodworking chisels, lathe tools, and other HSS implements.

Best For

Ideal for woodturners, machinists, and anyone who regularly sharpens high-speed steel cutting tools and desires a superior edge without the hassle of wheel dressing or excessive heat.

Pros and Cons

Pros:

- Maintains its shape and doesn’t require dressing.

- Sharpen tools quickly and efficiently, minimizing heat buildup.

- Exceptional longevity compared to abrasive wheels.

- Produces a very fine, precise edge (320 grit).

Cons:

- Higher initial cost than traditional abrasive wheels.

- Not suitable for carbide or non-ferrous metals.

Customer Reviews

Customer Review: Using the grinding wheel it helps with holding the heat down in shaping. The tools will hold a sharper edge for a longer time.

Customer Review: I spent a lot of time debating which grit to order. I ordered the finer grit and have to pay attention to build up, but one can go online and find out how to clean them up and keep them clean. I am sharpening tools that might be a little bit smaller than what the average person is using, but it performs beautifully.

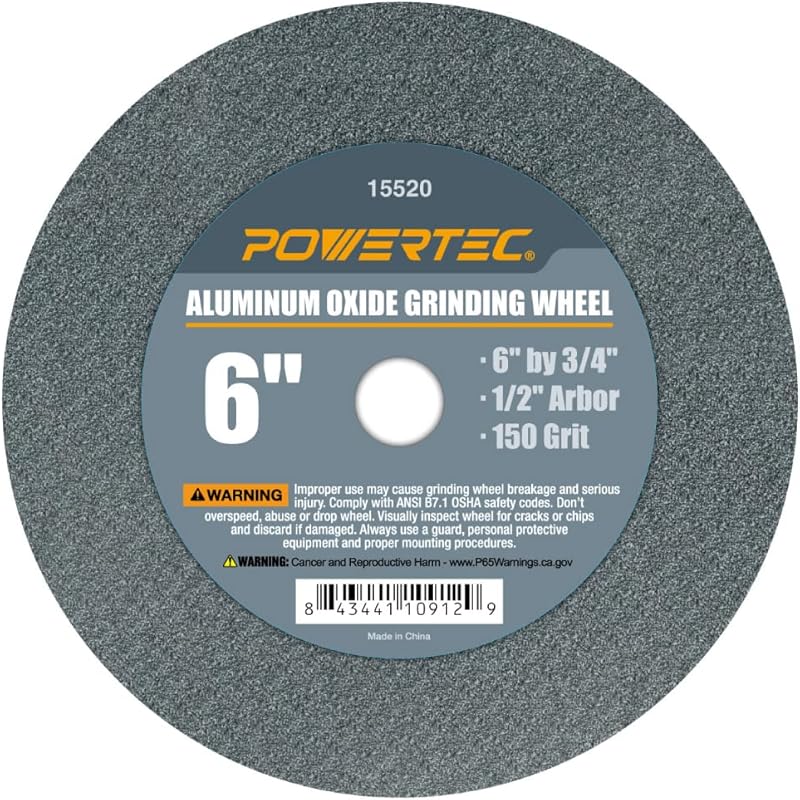

3. POWERTEC 6-inch Bench Grinder Wheel 150 Grit Aluminum Oxide for Sharpening Tools

The POWERTEC 6-inch bench grinder wheel with 150 grit aluminum oxide is a versatile and cost-effective choice for general sharpening and material removal. It strikes an excellent balance between aggressive cutting and a refined finish, making it ideal for various carbon and tool steel applications. Its durable construction is designed to withstand heavy-duty use while resisting common workshop chemicals.

Key Features That Stand Out

- ✓ 150 Grit Aluminum Oxide offers a good balance for sharpening and minor material shaping.

- ✓ Heavy-Duty Construction ensures durability and a long lifespan.

- ✓ Chemical Resistant to water, oils, and acids, extending usability in varied environments.

- ✓ Optimized for Carbon and Tool Steel (excluding carbide and ceramic tools).

Why We Recommend It

This POWERTEC grinding wheel is a fantastic budget-friendly option for general-purpose grinding and sharpening. It’s reliable, durable, and handles common workshop tasks effectively, making it a great value for those needing a dependable 6 inch aluminum oxide grinding wheel without breaking the bank.

Best For

Perfect for DIY enthusiasts, hobbyists, and professionals seeking an affordable yet effective wheel for sharpening common tools and performing light to moderate grinding on carbon and tool steel.

Pros and Cons

Pros:

- Excellent value for its price point.

- Good all-around grit for sharpening and general grinding.

- Durable aluminum oxide construction.

- Resistant to many common workshop chemicals.

Cons:

- Not suitable for harder materials like tungsten carbide.

- May require occasional dressing to maintain a flat surface.

Customer Reviews

Customer Review: My first order was labeled 150 grit but actually contained an 80 grit wheel. I tried using the “Contact Seller” option through Amazon, but that process was a bit slow and took a couple of days for a response. I ended up reordering and returning the wrong one, and the replacement arrived correctly. The wheel itself works great!

Customer Review: Attached without a hitch. Much finer grit than my old wheel. Works great!

4. POWERTEC 6 Inch Aluminum Oxide 60 Grit Grinder Wheel, 1/2″ Arbor, Sharpening Bench Tools

The POWERTEC 6-inch aluminum oxide 60 grit grinder wheel is your go-to for more aggressive material removal and initial sharpening tasks. With a coarser 60-grit, it’s adept at quickly shaping tools, removing burrs, and preparing surfaces on carbon and tool steel. Like its 150-grit counterpart, this wheel boasts a robust, chemical-resistant construction for lasting performance in demanding environments.

Key Features That Stand Out

- ✓ Aggressive 60 Grit for rapid material removal and initial tool shaping.

- ✓ Durable Aluminum Oxide composition ensures longevity and consistent performance.

- ✓ Resistant to Chemicals like water, oils, and acids, enhancing its workshop utility.

- ✓ Ideal for Carbon and Tool Steel (not recommended for tougher materials like carbide).

Why We Recommend It

We recommend this 6 inch grinding wheel for its ability to quickly tackle more demanding grinding jobs. If you need to remove significant material, reshape a dull tool, or deburr welds efficiently, the 60 grit is highly effective. It’s a workhorse for any workshop, providing quick results without compromising on durability.

Best For

This wheel is best suited for heavy-duty grinding, rough shaping of tools, initial sharpening of very dull edges, and removing rust or burrs on various carbon and tool steel workpieces.

Pros and Cons

Pros:

- Excellent for rapid material removal.

- Highly durable and built for tough applications.

- Chemical resistance adds to its lifespan.

- Effective for sharpening extremely dull tools quickly.

Cons:

- Too coarse for fine finishing work.

- Will wear faster than finer grit wheels under heavy use.

Customer Reviews

Customer Review: My first order was labeled 150 grit but actually contained an 80 grit wheel. I tried using the “Contact Seller” option through Amazon, but that process was a bit slow and took a couple of days for a response. I ended up reordering and returning the wrong one, and the replacement arrived correctly. The wheel itself works great! It’s aggressive enough for quick shaping.

Customer Review: Attached without a hitch. Much coarser grit than my old wheel, perfect for grinding down rough edges quickly. Works great!

5. 6 Inch Silicon Carbide Bench Grinder Wheel and Wire Brush for Sharpening

This unique set combines a 6 inch silicon carbide bench grinder wheel with a wire brush, offering a comprehensive solution for sharpening and cleaning tasks. The green silicon carbide wheel provides high hardness and wear resistance for sharpening, while the carbon wire brush is perfect for rust removal, deburring, and surface preparation. It’s a versatile duo for any bench grinder setup.

Key Features That Stand Out

- ✓ High-Quality Green Silicon Carbide Wheel for superior hardness, durability, and wear resistance.

- ✓ Included Premium Carbon Wire Brush for effective cleaning, sanding, and rust removal.

- ✓ Multi-Functional Set handles both sharpening and surface preparation.

- ✓ Standard 1/2-inch Arbor Hole ensures compatibility with most 6-inch bench grinders.

Why We Recommend It

This 6 inch grinder wheel and wire brush combo is an excellent choice for users looking for an all-in-one package to maintain their tools and clean workpieces. The silicon carbide wheel is particularly effective on non-ferrous metals and ceramics, broadening its utility beyond typical steel tools. It offers great value and versatility for diverse workshop needs.

Best For

Ideal for users who need a dual-purpose setup for sharpening various materials, including carbide-tipped tools, and for general cleaning, deburring, and rust removal on a bench grinder.

Pros and Cons

Pros:

- Provides both grinding and cleaning capabilities in one package.

- Silicon carbide is highly effective on hard and brittle materials.

- Wire brush is excellent for surface prep and rust removal.

- Good value for a two-piece set.

Cons:

- Silicon carbide can be more brittle than aluminum oxide.

- The wire brush may shed bristles over time with heavy use.

Customer Reviews

Customer Review: This set is fantastic! The silicon carbide wheel sharpens my ceramic knives beautifully, and the wire brush makes quick work of cleaning up old metal parts. Definitely a worthwhile upgrade for my bench grinder.

Customer Review: I was surprised by the quality of both the grinding wheel and the wire brush. They fit perfectly on my 6-inch grinder, and the performance is top-notch for both sharpening and rust removal. Highly recommend this combo.

Complete Buying Guide for 6 Inch Grinder Wheel

Essential Factors We Consider

When selecting the best 6 inch grinder wheel, several factors come into play beyond just the size. The grit of the wheel determines how aggressively it removes material, with lower numbers indicating coarser grits for rapid shaping and higher numbers for finer finishing. The material of the abrasive is crucial; aluminum oxide grinder wheels are common and excellent for general-purpose grinding on steel, while silicon carbide wheels are better for non-ferrous metals, cast iron, and carbide. CBN (Cubic Boron Nitride) wheels are a premium choice for high-speed steel, offering superior heat dissipation and tool life. Compatibility with your existing bench grinder, specifically the arbor hole size (typically 1/2-inch for 6-inch wheels), is paramount. Finally, consider the specific tasks you’ll perform: sharpening, deburring, shaping, or polishing, as each requires a different wheel type for optimal results.

💡 Related:

bench grinder wheel replacement

Budget Planning

The cost of a 6 inch grinder wheel can vary significantly based on its abrasive material and specialized features. Basic aluminum oxide wheels are generally the most affordable, making them an excellent choice for everyday use and for those on a tighter budget. Silicon carbide wheels are a step up in price but offer enhanced performance on specific materials. CBN wheels represent the highest investment, but their incredible durability, precision, and ability to handle high-speed steel without excessive heat can lead to long-term savings by preserving expensive tools and reducing replacement costs. Consider your frequency of use and the types of materials you’ll be working with to determine if a premium wheel’s long-term benefits outweigh its initial cost.

Final Thoughts

Investing in the right 6 inch grinder wheel is vital for maintaining your tools and efficiently tackling various metalworking and woodworking projects. By considering the grit, abrasive material, compatibility, and intended use, you can choose a wheel that maximizes performance and ensures safety. A well-selected bench grinder wheel not only improves the quality of your work but also extends the life of your tools and grinder.

Frequently Asked Questions

Q: What is the difference between aluminum oxide and silicon carbide grinder wheels?

A: Aluminum oxide grinder wheels are the most common type and are excellent for general-purpose grinding on ferrous metals like carbon steel and tool steel. They are tough and durable. Silicon carbide grinder wheels, on the other hand, are harder and sharper, making them ideal for grinding non-ferrous metals (aluminum, brass, copper), cast iron, ceramics, and carbide-tipped tools. They tend to fracture more easily, exposing new cutting edges.

💡 Related:

bench grinders for sharpening

Q: Can a 6 inch grinder wheel be used for sharpening chisels and plane irons?

A: Yes, a 6 inch grinder wheel is commonly used for sharpening chisels, plane irons, and other woodworking tools. For these tasks, a medium to fine grit (e.g., 120-320 grit) aluminum oxide wheel is typically recommended for initial shaping and sharpening, followed by a finer grit or buffing wheel for a razor-sharp edge. CBN wheels are particularly effective for sharpening high-speed steel tools due to their heat-reducing properties.

Q: How often should I dress my grinding wheel?

A: The frequency of dressing your grinding wheel depends on how often you use it and the type of material you’re grinding. Generally, you should dress your wheel whenever it becomes glazed, loaded with material, or starts to lose its original shape and concentricity. This process helps expose fresh abrasive material and restores the wheel’s cutting efficiency and flat profile.

Q: Is a 1/2-inch arbor hole standard for a 6 inch grinder wheel?

A: Yes, for most consumer-grade 6 inch bench grinders, a 1/2-inch arbor hole is the standard size. It’s always crucial to verify the arbor size required by your specific bench grinder before purchasing a new wheel to ensure proper fit and safe operation.

Q: Can I use a buffing wheel for sharpening?

A: A buffing wheel is designed for polishing and finishing, not for aggressive material removal or sharpening dull edges. While it can refine an already sharp edge and remove burrs when used with a polishing compound, it will not effectively sharpen a truly dull tool. For sharpening, you need an abrasive grinding wheel with an appropriate grit.

Choosing the right 6 inch grinder wheel is essential for optimizing your workshop’s capabilities and achieving precise results. Whether you need an aggressive wheel for rapid material removal, a fine grit for sharpening delicate tools, or a specialized option like a CBN wheel for high-speed steel, the market offers a diverse range of choices. Our expert-tested recommendations aim to guide you toward the perfect selection, ensuring your projects are executed with efficiency and excellence. Review our top picks and consider your specific needs to make an informed decision today!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.