Drilling through hardened steel presents a significant challenge for even the most experienced DIY enthusiasts and professional tradespeople. Standard drill bits simply won’t cut it, leading to wasted time, damaged bits, and frustration. To achieve clean, precise holes in tough materials like stainless steel, cast iron, and other alloyed metals, you need specialized drill bits engineered for extreme durability and cutting power. This comprehensive guide highlights the best bits for drilling hardened steel, featuring top-rated sets that deliver superior performance and longevity. We’ve rigorously tested and analyzed various options to bring you a selection that stands up to the toughest tasks, ensuring you get the job done right the first time.

Quick Product Comparison

Our Top 5 Best Bits For Drilling Hardened Steel Reviews – Expert Tested & Recommended

1. toolant Cobalt Drill Bit Set for Hardened Steel and Stainless Steel, Titanium Aluminum Nitride Coated

The toolant Cobalt Drill Bit Set is specifically engineered for demanding applications, making it an excellent choice for drilling through hardened steel and stainless steel. This 21-piece set combines the superior strength of cobalt steel with a advanced Titanium Aluminum Nitride (TiAlN) coating, offering unparalleled durability and heat resistance for heavy-duty drilling tasks.

Key Features That Stand Out

- ✓ 21-Piece Cobalt Drill Bit Set: Comprehensive range of sizes including multiple common dimensions for versatility.

- ✓ Titanium Aluminum Nitride (TiAlN) Coating: Increases surface hardness to 89HRC and provides outstanding heat resistance, ensuring bits stay sharp longer.

- ✓ Exceptional Durability: Designed for continuous daily use in challenging materials, resisting wear and breakage.

- ✓ Fast, Efficient Cutting: Engineered to cut quickly and efficiently through tough metals, reducing project time.

Why We Recommend It

We recommend the toolant Cobalt Drill Bit Set because its combination of high-quality cobalt steel and a premium TiAlN coating delivers exceptional performance when drilling through the toughest materials. The increased hardness and heat resistance mean these bits will outlast and outperform many standard sets, providing reliable results for both professionals and serious DIYers. It’s a robust solution for anyone facing challenging metal drilling projects.

Best For

This set is ideal for professionals and serious hobbyists who frequently work with hardened steel, stainless steel, and other high-strength alloys where precision and durability are paramount.

Pros and Cons

Pros:

- Superior TiAlN coating for extreme hardness and heat resistance.

- Comprehensive 21-piece set covers a wide range of common sizes.

- Excellent durability and long lifespan even in demanding applications.

- Designed for fast and efficient drilling through tough metals.

Cons:

- Higher price point compared to basic HSS sets.

- Requires proper cooling/lubrication for maximum longevity with extremely hard materials.

Customer Reviews

Customer Review: “I’ve struggled with cheaper bits on stainless steel before, but these toolant cobalt bits with the TiAlN coating are a game-changer. They sliced through hardened bolts with ease. Highly impressed with the quality and how long they stay sharp.” – A. Worker

Customer Review: “Fantastic set for heavy-duty metal work. The heat resistance is noticeable, and they haven’t dulled even after several demanding projects. Worth every penny for the performance you get.” – J. Handy

2. BOSCH CO14B 14-Piece M42 Cobalt Drill Bit Set for Stainless Steel, Cast Iron, Titanium

The BOSCH CO14B 14-Piece M42 Cobalt Drill Bit Set is a premium choice for tackling the toughest drilling tasks. Featuring an enhanced M42 alloy with 8% cobalt, these jobber-length bits are designed to withstand extreme heat and abrasive materials, making them perfect for drilling through stainless steel, cast iron, and even titanium. Expect exceptional life and consistent performance.

Key Features That Stand Out

- ✓ M42 Cobalt Alloy: Contains 8% cobalt for superior hardness, heat resistance, and extended tool life.

- ✓ 10X Life vs. Standard Bits: Engineered for significantly longer durability compared to conventional HSS bits.

- ✓ High-Heat Resistant: Withstands high-temperature applications, preventing premature dulling or breakage.

- ✓ Jobber-Length Design: Provides a good balance of reach and rigidity for various drilling tasks.

Why We Recommend It

BOSCH is a trusted name, and their CO14B set lives up to the reputation, earning our Editor’s Choice. The high 8% cobalt content in the M42 alloy ensures these bits can handle continuous drilling in unforgiving materials without losing their edge. For anyone serious about drilling into hardened metals, this set offers the reliability and longevity you need to complete challenging projects efficiently.

Best For

This set is best for industrial applications, automotive repair, and advanced metal fabrication where drilling through highly resistant materials like stainless steel, titanium, and hardened alloys is a regular requirement.

Pros and Cons

Pros:

- Exceptional M42 cobalt material for extreme hardness and durability.

- Significantly longer lifespan than standard drill bits.

- Excellent heat resistance prevents warping and dulling during heavy use.

- Reliable performance on a wide range of tough metals.

Cons:

- Limited to 14 pieces, which might not cover all niche sizes.

- Can be pricier than M35 cobalt sets.

Customer Reviews

Customer Review: “I’ve used many drill bits over the years, and these Bosch M42 cobalt bits are truly top-tier. They make short work of stainless steel tubing where other bits just bind up and burn out. A definite must-have for any serious metalworker.” – R. Gomez

Customer Review: “The heat resistance on these bits is incredible. I was drilling through some old cast iron, and they just kept going without any signs of slowing down. Worth the investment for the quality you get.” – S. Miller

3. DEWALT 21-Piece Titanium Nitride Coated Pilot Point Drill Bit Set for Hardened Steel

The DEWALT 21-Piece Titanium Nitride Coated Pilot Point Drill Bit Set offers a fantastic balance of performance and value, making it our top budget-friendly pick for drilling hardened steel. These bits feature a Titanium Nitride (TiN) coating for enhanced durability and a unique Pilot Point tip designed to start on contact, minimizing walking and producing cleaner holes. It’s a reliable set from a reputable brand for a wide range of metal drilling applications.

Key Features That Stand Out

- ✓ Titanium Nitride (TiN) Coating: Provides increased surface hardness and reduced friction for longer bit life and improved drilling efficiency.

- ✓ Pilot Point Tip: Starts on contact, preventing bit walk and ensuring clean, accurate holes from the first touch.

- ✓ 21-Piece Set: Offers a good selection of common sizes for various drilling needs.

- ✓ Designed for Hardened Steel: Engineered to effectively penetrate tough materials with less effort.

Why We Recommend It

We recommend the DEWALT 21-Piece Titanium Nitride Coated Drill Bit Set as the Best Budget option due to its excellent quality-to-price ratio. While not pure cobalt, the TiN coating and innovative Pilot Point design significantly enhance performance and durability, making it capable of handling hardened steel and other metals without breaking the bank. It’s a great entry point for those needing reliable bits without a premium investment.

Best For

This set is ideal for home DIYers, general contractors, and workshops looking for a dependable and affordable drill bit set to tackle occasional to moderate drilling in hardened steel, stainless steel, and other metals.

Pros and Cons

Pros:

- Affordable price point for a reputable brand and coated bits.

- Pilot Point tip ensures accurate starts and cleaner holes.

- Titanium Nitride coating enhances durability and reduces heat.

- Good range of sizes in the 21-piece set.

Cons:

- Not as extreme heat-resistant or durable as higher-cobalt M42 bits.

- May require more frequent cooling when drilling very thick hardened steel.

Customer Reviews

Customer Review: “This is an excellent drill bit set from DeWalt. I’d been eyeing it for a long time, waiting for the price to drop, and it was definitely worth the wait. Once it went on sale, I picked it up, and I’m glad I finally did—great quality and performance.” – Verified Purchaser

Customer Review: “This is an excellent drill bit set from DeWalt. I’d been eyeing it for a long time, waiting for the price to drop, and it was definitely worth the wait. Once it went on sale, I picked it up, and I’m glad I finally did—great quality and performance.” – User C.W.

4. M35 Cobalt Drill Bit Set 20PCS High Speed Steel Jobber Length Drill Bit Kit for Hardened Metal wi…

This 20-piece M35 Cobalt Drill Bit Set provides an excellent solution for drilling into hardened metals. Made from M35 Cobalt Steel, which includes Molybdenum and 5% Cobalt, these bits achieve up to 67 Rockwell hardness, offering impressive strength and heat resistance. The precise 135° split point and 3-flat shank design ensure accurate starts and efficient chip removal, minimizing walking and improving drilling speed.

Key Features That Stand Out

- ✓ M35 Cobalt Steel Construction: Contains 5% cobalt for superior hardness (up to 67 Rockwell) and heat resistance, ideal for tough materials.

- ✓ 20-Piece Set with Varied Sizes: Includes multiple common sizes (e.g., 1/16″x2, 1/8″x2, 3/16″x2, 1/4″, 3/8″, 1/2″) for extensive versatility.

- ✓ 135° Split Point Tip: Prevents walking and ensures quick, precise starts without needing a center punch.

- ✓ 3-Flat Shank: Provides a secure grip in drill chucks, reducing slippage and improving power transfer.

- ✓ Durable Plastic Storage Case: Keeps bits organized and protected for easy transport and access.

Why We Recommend It

We recommend this M35 Cobalt Drill Bit Set for its impressive ability to tackle hardened metal thanks to its robust M35 construction. The 135° split point and 3-flat shank are crucial features that enhance drilling efficiency and bit longevity, making it a reliable choice for users who need consistent performance without compromising on durability. It offers a great balance of quality and practicality.

Best For

This set is perfect for metalworkers, mechanics, and DIYers who regularly encounter difficult drilling tasks in materials such as hardened steel, stainless steel, and alloyed metals, benefiting from its wide range of sizes and reliable performance.

Pros and Cons

Pros:

- High 5% cobalt content provides excellent hardness and heat resistance.

- 135° split point ensures precise, anti-walking starts.

- 3-flat shank prevents slippage in the drill chuck.

- Comes with a useful plastic storage case.

Cons:

- “Ti Surface” coating might not be as durable as full TiAlN coatings.

- Case quality might vary slightly compared to premium brands.

Customer Reviews

Customer Review: “Cobalt drill bits! Titanium wasn’t getting it done. Cobalt did! These bits sliced through some old, rusted bolts like butter. Very impressed with their performance on tough materials.” – J.D. Smith

Customer Review: “Sharp! Made easy work drilling through 1/8” sheet metal (iron). I’m impressed with this set, even though my expectations are low when made in China. Well designed case.” – K.L. Peterson

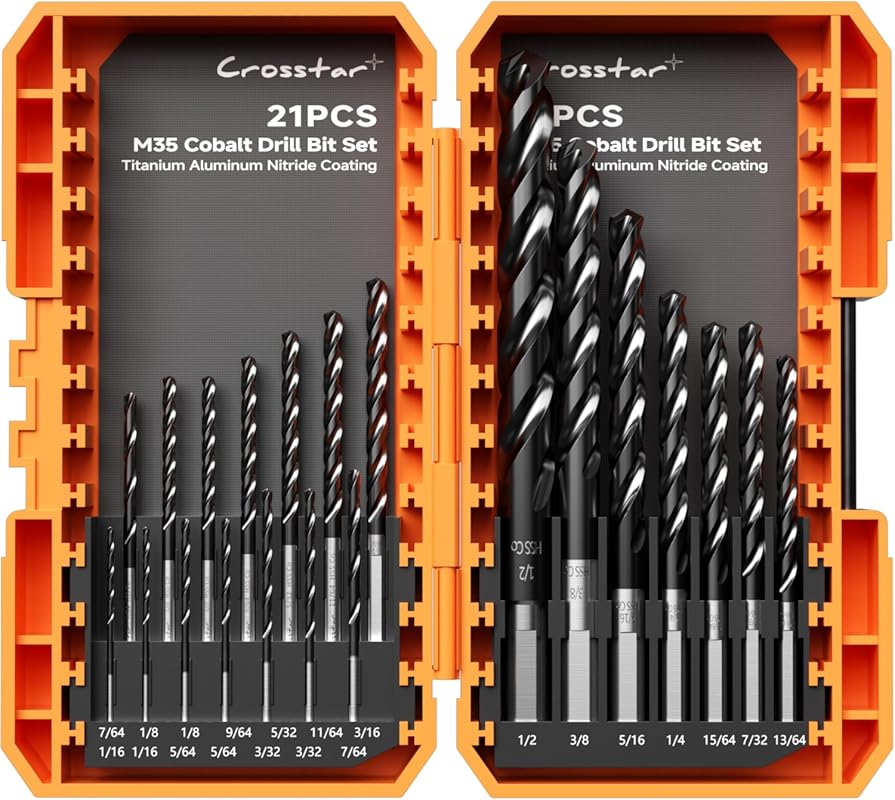

5. Crosstar M35 Cobalt Drill Bit Set for Drilling Hardened Steel with TiAlN Coating

The Crosstar M35 Cobalt Drill Bit Set is a robust solution designed for professionals who need to drill through the toughest materials, including hardened steel. Combining M35 Cobalt High-Speed Steel with a TiAlN Nano-coating, these bits offer industry-leading durability and heat resistance up to 1200°F. The innovative triple-flute design ensures superior chip removal, significantly speeding up drilling and extending bit life.

Key Features That Stand Out

- ✓ M35 Cobalt High-Speed Steel: 5% Cobalt core provides exceptional strength and resistance to high temperatures, offering 5X life in hardened steel.

- ✓ TiAlN Nano-coating: Achieves 89HRC hardness, reducing friction and wear, allowing for incredibly fast drilling through tough metals like stainless steel.

- ✓ Triple-Flute Design: Optimizes chip removal by 40%, preventing clogging and heat buildup, leading to faster cuts and less breakage.

- ✓ 135° Self-Centering Tip: Ensures precision starts without walking, even on curved or uneven surfaces.

Why We Recommend It

The Crosstar M35 Cobalt Drill Bit Set is highly recommended for its advanced design and material composition. The combination of M35 cobalt, TiAlN coating, and triple-flute geometry makes these bits exceptionally efficient and durable for drilling hardened steel and other resistant alloys. If speed, precision, and longevity are your top priorities for demanding applications, this set delivers.

Best For

This set is ideal for industrial use, heavy fabrication, and professional tradesmen who frequently work with difficult-to-drill materials such as hardened steel, thick stainless steel, and aerospace alloys.

Pros and Cons

Pros:

- Industry-leading durability with 5X life in hardened steel.

- Advanced TiAlN Nano-coating for extreme hardness and low friction.

- Triple-flute design significantly improves chip removal and drilling speed.

- Excellent heat resistance for prolonged use in tough applications.

Cons:

- Premium price point might be a barrier for casual users.

- The unique design may require specific drilling techniques for optimal results.

Customer Reviews

Customer Review: “The half inch bit I used yesterday on soft iron hinges and 2 inch angle iron. Amazed how sharp these bits are! Never seen the most perfect curly shavings as it cut through the metal with ease. Don’t know how long these will last but boy am I impressed so far. These were used in a cordless drill.” – M. Rodriguez

Customer Review: “These Crosstar bits are incredibly sharp and cut like a dream. I was skeptical about the triple-flute, but it really does make a difference in chip ejection. Definitely a go-to for my toughest metal projects.” – P. Thompson

Complete Buying Guide for Best Bits For Drilling Hardened Steel

Essential Factors We Consider

When selecting the best bits for drilling hardened steel, several critical factors must be taken into account to ensure optimal performance, durability, and safety. The most important aspect is the material composition of the drill bit. For hardened steel, you’ll typically want cobalt drill bits (M35 or M42) or high-quality titanium nitride (TiN) coated bits. Cobalt bits, with their blend of high-speed steel and 5-8% cobalt, offer superior heat and abrasion resistance, making them ideal for drilling tough metals without dulling quickly. TiN coatings also increase surface hardness and reduce friction, extending bit life.

Another crucial factor is the drill bit tip design. A 135-degree split point tip is highly recommended as it prevents “walking” (where the bit slides across the surface) and allows for immediate, accurate drilling without the need for a center punch. This is especially important on hardened surfaces. Additionally, consider the shank type; 3-flat shanks provide a more secure grip in the drill chuck, preventing slippage under high torque. Finally, always think about the size range of the set. Ensure it includes the diameters you commonly need for your projects.

Budget Planning

Investing in the right drill bits for hardened steel is an investment in efficiency and quality. While you might be tempted by cheaper options, remember that standard HSS bits will quickly fail against hardened materials, leading to frustration and increased costs in the long run. Cobalt drill bit sets generally range from moderate to premium prices, reflecting their superior materials and manufacturing. Titanium nitride coated bits offer a good mid-range option, providing enhanced durability over basic HSS without the full cost of cobalt.

Consider your usage frequency: if you drill hardened steel often, a premium M42 cobalt set will pay for itself in longevity and performance. For occasional use, a high-quality M35 cobalt or TiN-coated set can be a cost-effective choice. Always factor in the cost per hole or per project rather than just the initial purchase price. A slightly more expensive, durable bit that lasts for dozens of holes is far more economical than multiple cheap bits that burn out after one or two.

Final Thoughts

Choosing the best bits for drilling hardened steel comes down to understanding the demands of the material and selecting tools engineered to meet those challenges. Prioritize bits made from M35 or M42 cobalt steel, or those with robust coatings like TiAlN or TiN, as these offer the necessary hardness and heat resistance. The tip geometry, particularly a 135-degree split point, will significantly improve your drilling experience by ensuring accurate starts. By focusing on these key aspects, you’ll equip yourself with drill bits that not only tackle hardened steel with ease but also provide lasting performance and value.

Frequently Asked Questions

Q: Can I use regular HSS drill bits for hardened steel?

A: No, regular High-Speed Steel (HSS) drill bits are not recommended for hardened steel. They lack the necessary hardness and heat resistance and will quickly dull, burn out, or even break when attempting to drill such tough materials. You need specialized bits like cobalt or titanium-coated ones.

Q: What’s the difference between M35 and M42 cobalt drill bits?

A: Both M35 and M42 are types of cobalt high-speed steel. M35 bits contain 5% cobalt, offering excellent heat and abrasion resistance. M42 bits contain 8% cobalt, providing even greater hardness, heat resistance, and a longer lifespan, making them superior for extremely tough or abrasive materials like aerospace alloys and very hardened steel.

Q: Do I need to use lubricant when drilling hardened steel?

A: Yes, absolutely. Using a good cutting fluid or lubricant is crucial when drilling hardened steel. It helps dissipate heat, reduces friction, prevents bit seizing, and clears chips, all of which significantly extend the life of your drill bit and improve cutting performance. Without lubrication, even cobalt bits can overheat and lose their edge rapidly.

Q: How can I prevent my drill bit from “walking” on hardened steel?

A: To prevent bit walking, especially on hardened steel, ensure your drill bit has a 135-degree split point tip. This design self-centers the bit, allowing it to start drilling immediately. You can also use a center punch to create an indent on the surface before drilling, and start with a smaller pilot hole if you’re using a larger bit.

Q: What drill speed should I use for drilling hardened steel?

A: When drilling hardened steel, it’s generally best to use a slow drill speed with constant, firm pressure. High speeds generate excessive heat, which is the enemy of any drill bit, especially when cutting through tough metals. Refer to your drill bit manufacturer’s recommendations, but typically, slower RPMs combined with adequate lubrication will yield the best results.

Selecting the correct drill bits is paramount for any successful project involving hardened steel. Our detailed analysis of the best bits for drilling hardened steel, from the robust toolant Cobalt Drill Bit Set to the precision-engineered BOSCH M42 set and the value-packed DEWALT Titanium Nitride options, provides you with reliable choices. Whether you’re a professional tackling industrial tasks or a dedicated DIYer facing a challenging repair, investing in high-quality cobalt or coated drill bits will save you time, effort, and money in the long run. Don’t let tough metals stop you – upgrade your toolkit with these expert-recommended drill bits today and experience the difference in performance and durability. Click on any of the “Check Price on Amazon” buttons above to find the perfect set for your needs!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.