Finding the right amount of power to weld 10mm steel isn’t easy. It depends on many things like the metal type and joint style. For 5-10mm thick steel, you might need 130-190 amps. The welding rod type and how you position the work can change this too. So, testing on scrap is a good idea to get the perfect settings for your job.

Amperage Requirements for Stick Welding

Several factors influence the amperage needed for stick welding. The type of metal, like mild steel or stainless steel, plays a big part. Metal thickness is important too; thicker materials need more amperage.

Joint types and preparation, such as beveling edges, can change amperage needs. So can welding positions and how strong and deep you want the weld.

Factors Affecting Amperage Needs

Type of Metal

Metal type, whether it’s mild steel or stainless steel, affects the needed amperage. Each metal conducts electricity and melts differently. This means you have to adjust amperage for the best weld results.

Metal Thickness

The thickness of the metal being welded is key. Thicker metals usually need higher amperages. For 5-10mm steel, you might need between 130 to 190 amps.

Joint Type and Preparation

The type of joint and how it’s prepared also matters. Good joint prep can reduce amperage needs. Certain joints need more amperage for the best welds.

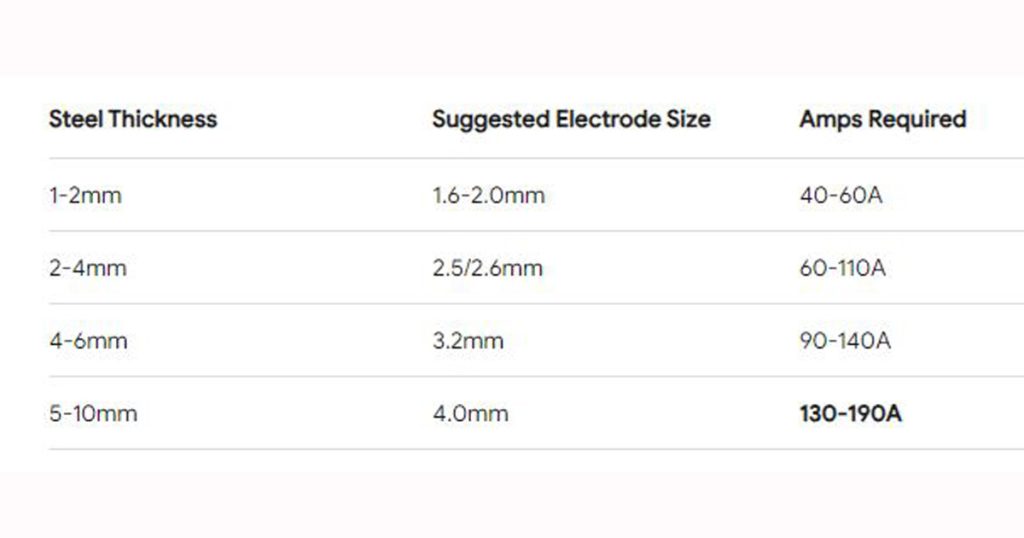

Amperage Guide for Stick Welding Steel

When you weld steel using the stick method, known as SMAW or MMA, the right amperage changes. It depends on the electrode and how thick the metal is. General rulebooks offer settings for different steel thicknesses and electrodes.

General-Purpose Electrodes (6013 Series)

For common 6013 electrodes, here’s the amperage range:

- 50-70 amps for 2mm steel

- 70-100 amps for 2.5mm steel

- 100-140 amps for 3.2mm steel

- 140-190 amps for 4mm steel

- 190-240 amps for 5mm steel

Low-Hydrogen Electrodes (7016 and 7018 Series)

Low-hydrogen types like 7016 and 7018 need different amperages:

- 30-50 amps for 2mm steel

- 40-70 amps for 2.5mm steel

- 60-90 amps for 3.2mm steel

- 90-120 amps for 4mm steel

- 120-170 amps for 5mm steel

Stainless Steel and Cast Iron Electrodes

Stainless steel and cast iron electrodes work within this range:

- 70-100 amps for 2.5mm steel

- 100-130 amps for 3.2mm steel

- 130-150 amps for 4mm steel

- 150-170 amps for 5mm steel

Remember, these are just starting points. The best settings can depend on how you weld, the joint, and your own choice. It’s smart to test on scrap first to find your best settings for welding steel with a stick.

How Many Amps Does It Take to Weld 10mm Steel?

Typical Amperage Range for 10mm Steel

Welding 10mm thick steel needs about 130-190 amps, as per the experts. This is for a basic joint with standard or low-hydrogen electrodes. The exact amps might change based on the joint type and prep work.

Considerations for Joint Type and Preparation

The amperage necessary varies with the joint type and prep work. For instance, a V-prep butt joint might need less power than a square-edge one. This is because the V-prep lets the weld go deeper. The welding position, like if it’s done flat or vertical, also affects the best amps for welding 10mm steel.

Image by mig-welding .co.uk

Choosing the Right Polarity for MMA Welding

For stick (MMA) welding, the polarity choice greatly affects the weld’s look and function. Polarity is about the electric connections among the welder, the electrode, and the metal being worked. Knowing the difference between DC+ (DCEP) and DC- (DCEN) will help pick the best for MMA projects.

DC+ (DCEP) Polarity

In DC+ (DCEP) setup, the positive terminal hooks to the work lead. The negative terminal connects to the earth lead. This setting boosts weld depth and focuses more heat on the metal, which is good for welding thick pieces.

DC- (DCEN) Polarity

DC- (DCEN) means the earth lead goes to the positive terminal. The work lead goes to the negative one. It creates a broader, shallower weld puddle. This is great for welding thinner materials quickly.

The best polarity can change based on the electrode, the job’s needs, and what kind of weld you want. Always check the manual or do some tests on scrap to find the right polarity. This helps get the best welds and work more efficiently.

Conclusion

Figuring out the right amperage for welding 10mm steel needs a few steps. Think about what type of metal you’re working with, how thick it is, and what kind of joint you’re making. Also, take into account how you’ve prepared everything and the welding tools and methods you’ll use.

It’s important that welders know about the factors that change amperage needs. This helps them make strong, dependable welds on steel and other metals. They need to know the right amperage for different steel thicknesses and understand what influences this.

In the end, getting the amperage right is all about careful planning and testing. Being informed and adjusting for each job means welders can do great work. Even with tough materials like 10mm steel, they can still make top-notch welds.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.