Are you looking for a welding method that is cost-effective, easy to use, and eliminates the need for gas cylinders? Look no further than gasless flux core welding. This innovative technique allows you to weld without the need for an external shielding gas, making it ideal for outdoor and remote projects.

Gasless flux core welding uses a special welding wire with a flux core that releases a protective gas when it melts. This gas forms a shield around the weld, preventing contamination and ensuring strong, high-quality welds. The flux within the wire also acts as a cleaning agent, removing impurities and producing clean and smooth welds.

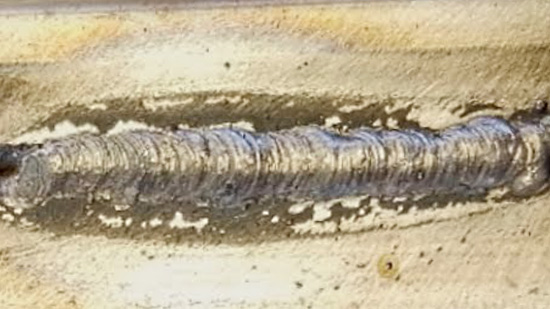

Image by oceanproperty.co.th

Gasless flux core welding?

Gasless flux core welding is a welding technique that eliminates the need for an external shielding gas. Instead, it uses a special welding wire with a flux core that releases a protective gas when it melts. This gas forms a shield around the weld, preventing contamination and ensuring strong, high-quality welds. The flux within the wire also acts as a cleaning agent, removing impurities and producing clean and smooth welds.

The key difference between gasless flux core welding and traditional welding methods is the absence of an external shielding gas. This makes gasless flux core welding a cost-effective and convenient option, especially for outdoor and remote projects where access to gas cylinders may be limited. Additionally, gasless flux core welding offers deeper penetration and better control over the welding process.

Advantages of gasless flux core welding

Gasless flux core welding offers several advantages over traditional welding methods. One of the main advantages is the elimination of the need for an external shielding gas. This not only reduces the overall cost of welding but also makes it more convenient, especially for projects in outdoor or remote locations where access to gas cylinders may be limited.

Another advantage of gasless flux core welding is its ability to provide deep penetration. The flux within the wire helps to create a strong and stable arc, allowing for better control over the welding process. This makes gasless flux core welding suitable for a wide range of applications, including welding thick materials and creating strong and durable welds.

Gasless flux core welding is also known for producing clean and smooth welds. The flux within the wire acts as a cleaning agent, removing impurities and contaminants from the weld area. This results in high-quality welds that are free from defects and have excellent visual appearance.

Gasless flux core welding vs. traditional welding methods

Gasless flux core welding offers several advantages over traditional welding methods, such as shielded metal arc welding (SMAW) and gas metal arc welding (GMAW). One of the main differences is the absence of an external shielding gas in gasless flux core welding.

In traditional welding methods, an external shielding gas, such as argon or carbon dioxide, is used to protect the weld area from contamination. This gas creates a shield around the weld, preventing atmospheric gases from reacting with the molten metal. However, in gasless flux core welding, the flux within the wire releases a protective gas when it melts, eliminating the need for an external shielding gas.

Another difference is the ability of gasless flux core welding to provide deep penetration. The flux within the wire helps to create a strong and stable arc, allowing for better control over the welding process. This makes gasless flux core welding suitable for a wide range of applications, including welding thick materials and creating strong and durable welds.

Equipment for gasless flux core welding

To get started with gasless flux core welding, you will need a few essential pieces of equipment. Here is a breakdown of the equipment required for gasless flux core welding:

Welding machine

A welding machine capable of performing gasless flux core welding is essential. Look for a machine that has the necessary voltage and amperage settings to suit your welding needs.

Gasless flux core welding wire

Gasless flux core welding wire is specifically designed for this welding technique. It has a flux core that releases a protective gas when it melts, forming a shield around the weld. Make sure to choose the right wire diameter for your welding project.

Welding helmet

A welding helmet is essential for protecting your eyes and face from the intense light and heat generated during the welding process. Look for a helmet that provides adequate protection and has a suitable shade level for gasless flux core welding.

Welding gloves

Welding gloves are necessary to protect your hands from sparks, heat, and potential burns. Choose gloves that are heat-resistant and provide a good grip for better control over the welding process.

Welding apron or jacket

A welding apron or jacket is recommended to protect your body from sparks and molten metal. Look for a flame-resistant and durable apron or jacket that provides full coverage.

Welding pliers or wire cutters

Welding pliers or wire cutters are useful for trimming excess wire and removing spatter from the weld area. Choose pliers or cutters that are specifically designed for welding applications.

Safety precautions for gasless flux core welding

While gasless flux core welding offers convenience and efficiency, it is essential to prioritize safety. Here are some safety precautions to follow when performing gasless flux core welding:

Wear protective gear

Always wear appropriate protective gear, including a welding helmet, gloves, apron or jacket, and safety glasses. These will protect you from sparks, heat, and potential burns.

Work in a well-ventilated area

Gasless flux core welding produces fumes and smoke, so it is important to work in a well-ventilated area. If working indoors, ensure proper ventilation or use exhaust fans to remove fumes from the work area.

Use a welding screen or curtains

Setting up a welding screen or curtains around the work area can help to protect others from harmful UV rays and flying sparks.

Keep a fire extinguisher nearby

Accidents can happen, so it is important to have a fire extinguisher nearby to quickly extinguish any potential fires.

Inspect and maintain equipment

Regularly inspect and maintain your welding equipment to ensure it is in good working condition. Replace any damaged or worn-out parts promptly.

Safety should always be your top priority when performing any welding operation. Follow these precautions to ensure a safe and productive welding experience.

Tips for successful gasless flux core welding

To achieve successful gasless flux core welding, here are some tips to keep in mind:

Clean the workpiece

Ensure the workpiece is clean and free from rust, oil, and other contaminants. Use a wire brush or grinder to remove any surface impurities before welding.

Set the correct voltage and amperage

Refer to the manufacturer’s guidelines to determine the appropriate voltage and amperage settings for your specific welding wire and workpiece thickness. Adjust the settings accordingly for optimal welding performance.

Maintain the correct travel speed

Keep a steady and consistent travel speed to ensure proper fusion and penetration. Welding too fast or too slow can result in weak welds or excessive spatter.

Watch for proper wire feeding

Ensure the welding wire is feeding smoothly and consistently. If you encounter wire feeding issues, check for any obstructions or kinks in the wire and adjust the wire feed speed accordingly.

Practice proper technique

Maintain a stable welding position and use a slight weaving motion while welding to ensure even penetration. Practice your technique on scrap pieces before working on your actual project.

Pay attention to the weld appearance

Check the appearance of the weld bead to ensure it is smooth, uniform, and free from defects such as porosity or undercut. Adjust your welding parameters as needed to achieve the desired weld appearance.

Practice makes perfect. Take the time to familiarize yourself with the gasless flux core welding process and practice on various materials and thicknesses to improve your skills.

Common applications of gasless flux core welding

Gasless flux core welding is a versatile welding method that finds applications in various industries and projects. Some common applications include:

Construction

Gasless flux core welding is often used in construction projects, such as welding structural steel, reinforcing bars, and metal frames. Its deep penetration capabilities and ease of use make it ideal for these applications.

Automotive repair

Gasless flux core welding is commonly used in automotive repair shops for tasks such as repairing exhaust systems, welding body panels, and fabricating custom parts. Its portability and ability to weld in windy conditions make it a convenient choice for automotive repairs.

Farm and ranch equipment

Gasless flux core welding is widely used in the agricultural industry for repairing and fabricating farm and ranch equipment. Its versatility allows for welding a variety of materials commonly found in this industry, such as steel and aluminum.

DIY projects

Gasless flux core welding is popular among DIY enthusiasts for various projects, including creating metal sculptures, building furniture, and repairing household items. Its cost-effectiveness and ease of use make it an attractive option for those looking to tackle their own welding projects.

These are just a few examples of the many applications where gasless flux core welding can be used. Its versatility and convenience make it a valuable tool in various industries and projects.

Choosing the right gasless flux core welding wire

Choosing the right gasless flux core welding wire is essential for achieving optimal welding results. Here are some factors to consider when selecting the right wire:

Wire diameter

Gasless flux core welding wires come in different diameters, typically ranging from 0.030 to 0.045 inches. The wire diameter you choose will depend on the thickness of the material you are welding. Refer to the manufacturer’s guidelines for the recommended wire diameter for your specific application.

Material compatibility

Consider the type of material you will be welding. Gasless flux core welding wires are available for welding different materials, including mild steel, stainless steel, and aluminum. Ensure the wire you choose is compatible with the material you are working with.

Tensile strength

Pay attention to the tensile strength of the welding wire. The tensile strength determines the strength of the weld and its ability to withstand stress. Refer to the manufacturer’s specifications for the tensile strength of the wire and choose accordingly based on your project requirements.

Flux type

Gasless flux core welding wires use different types of flux, each with its own characteristics. Some fluxes are designed for deep penetration, while others are better suited for welding in windy conditions. Consider the specific requirements of your project and choose a wire with the appropriate flux type.

Manufacturer reputation

Look for reputable manufacturers that produce high-quality welding wires. Read reviews and seek recommendations from experienced welders to ensure you are choosing a reliable brand.

By considering these factors, you can select the right gasless flux core welding wire for your specific welding needs, ensuring optimal performance and weld quality.

Troubleshooting common issues in gasless flux core welding

Gasless flux core welding, like any welding process, can sometimes encounter issues that affect the quality of the welds. Here are some common issues and troubleshooting tips to help you overcome them:

Excessive spatter

Excessive spatter can occur when the wire feed speed is too high or when the contact tip is worn or clogged. Reduce the wire feed speed or replace the contact tip if necessary. Additionally, cleaning the workpiece thoroughly before welding can help reduce spatter.

Porosity

Porosity, which appears as small holes in the weld, can be caused by contamination or inadequate shielding. Ensure the workpiece is clean and free from oil, rust, or other contaminants. Maintain a consistent travel speed and ensure proper shielding during the welding process.

Lack of fusion

Lack of fusion occurs when the weld fails to fuse properly with the base metal. This can happen due to insufficient heat or improper welding technique. Increase the heat settings and adjust your technique to ensure proper fusion.

Burn-through

Burn-through can occur when welding thin materials or using excessive heat. Reduce the heat settings and adjust the travel speed to prevent burn-through. You can also use a backing plate or copper backing to help dissipate heat.

Uneven weld bead

An uneven weld bead can be caused by inconsistent travel speed or improper welding technique. Maintain a steady travel speed and use a slight weaving motion while welding to ensure an even weld bead.

If you encounter any issues during gasless flux core welding, don’t get discouraged. Troubleshoot the problem using the tips mentioned above, and with practice, you will improve your welding skills and achieve high-quality welds.

Conclusion

Gasless flux core welding is a cost-effective, versatile, and easy-to-use welding technique that eliminates the need for an external shielding gas. With its deep penetration capabilities and ability to weld in windy conditions, gasless flux core welding is a convenient solution for a wide range of applications.

By understanding the equipment, following safety precautions, and practicing proper technique, you can achieve successful gasless flux core welding. Whether you’re a professional welder or a DIY enthusiast, gasless flux core welding offers a convenient and efficient solution for your welding needs.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.