Welcome, fellow woodworkers! Finding the best miter saw blade for woodworking can truly transform your projects, making cuts cleaner, smoother, and more precise. A high-quality blade isn’t just an accessory; it’s a critical tool that enhances safety, improves efficiency, and elevates the final finish of your work. Whether you’re crafting intricate furniture, installing trim, or tackling a large framing job, having the right blade for your miter saw makes all the difference. We’ve put together a list of top-performing blades designed specifically for woodworking applications, tested for their durability, cut quality, and overall value, to help you make an informed decision.

Quick Product Comparison

Our Top 5 Best Miter Saw Blade For Woodworking Reviews – Expert Tested & Recommended

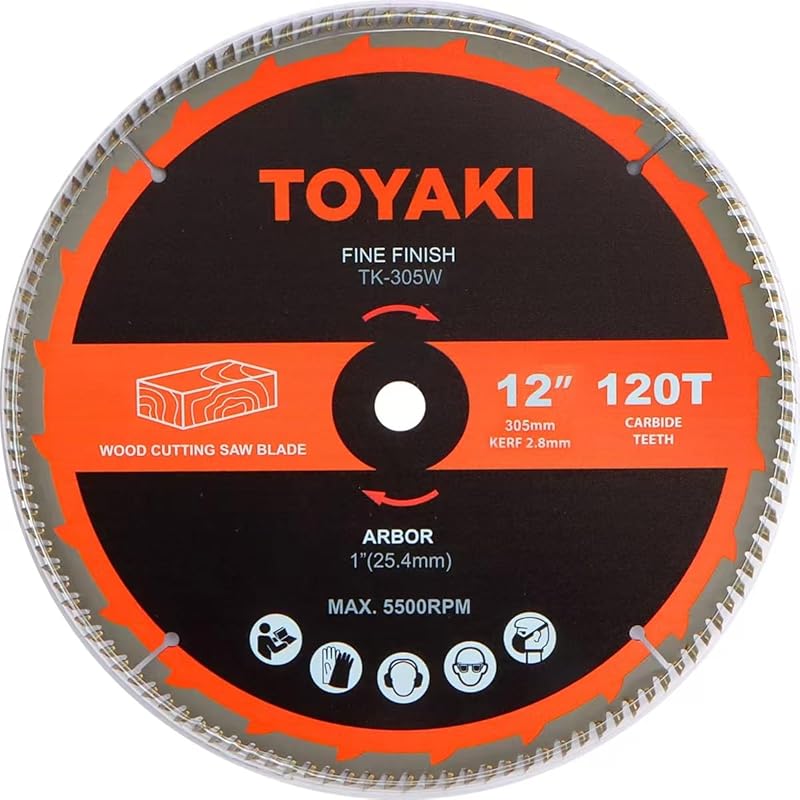

1. TOYAKl 12-Inch Miter Saw Blade,120-Tooth Carbide-Tipped Fine-Finish Professional Woodworking Saw …

The TOYAKl 12-Inch Miter Saw Blade stands out for its impressive 120-tooth count, making it ideal for achieving exceptionally smooth and fine finishes in woodworking. This carbide-tipped blade is designed for precision, ensuring consistent quality throughout its lifespan. It’s a professional-grade option that prioritizes clean cuts and reduced vibration for superior results.

Key Features That Stand Out

- ✓ 120-Tooth Design: Engineered for ultra-fine finish woodworking, leaving virtually no tear-out.

- ✓ Carbide-Tipped Teeth: Provides exceptional sharpness and extended durability for prolonged use.

- ✓ Reduced Vibration: Specialized tooth pattern ensures smooth operation and accurate cuts.

- ✓ Consistent Quality: Maintains cutting performance throughout its working life.

Why We Recommend It

We highly recommend the TOYAKl 12-inch blade for its commitment to fine-finish woodworking. If you’re tired of rough edges and inconsistent cuts, this blade delivers the precision you need. Its high tooth count is perfect for delicate projects where every cut needs to be flawless, making your work look professionally done.

Best For

This blade is best for finish carpenters, cabinet makers, and DIY enthusiasts focusing on projects that require an ultra-smooth, clean cut on various woods, especially trim work and furniture components.

Pros and Cons

Pros:

- Excellent for ultra-fine finishing with minimal tear-out.

- Carbide-tipped teeth ensure long-lasting sharpness.

- Reduces vibration for a smoother cutting experience.

- Offers professional-grade performance at a competitive price point.

Cons:

- Higher tooth count may cut slower on very thick materials.

- Not ideal for rough cutting or heavy construction tasks.

Customer Reviews

Customer Review: “Works great, especially at this price. Cannot speak to longevity yet but it does cut cleanly.”

Customer Review: “I used this saw blade in my miter saw to cut the trim for my kitchen cabinets. Smooth and no burrs. I recommend this blade and I bought another for my table saw.”

2. 10-Inch 40-Tooth Circular Saw Blade, Max 7000 RPM, Fine Finish Wood Crosscutting, Tungsten Carbid…

The 10-Inch 40-Tooth Circular Saw Blade is a versatile workhorse, perfect for fine finish crosscutting in various woodworking projects. With its tungsten carbide teeth and a thin kerf design, it promises efficient and smooth cuts at speeds up to 7000 RPM. This blade offers a great balance of durability and cutting performance for everyday tasks.

Key Features That Stand Out

- ✓ Universal Compatibility: Features a 10-inch diameter and 5/8-inch arbor, fitting most miter and table saws.

- ✓ Durable Construction: Made from high-quality alloy steel with tough tungsten carbide teeth for extended life.

- ✓ Efficient Cutting: Thin kerf design and sharp teeth allow for fast, smooth cuts at up to 7000 RPM.

- ✓ Fine Finish Crosscutting: Designed to provide clean edges on wood, suitable for detailed projects.

Why We Recommend It

We’ve selected this 40-tooth blade as an Editor’s Choice because it strikes an excellent balance between speed, durability, and the ability to produce clean cuts. It’s a reliable option for both enthusiastic DIYers and professionals who need a dependable blade for general woodworking tasks, from framing to fine crosscutting.

Best For

This is an ideal blade for general woodworking, crosscutting, and projects where both speed and a decent finish are required, such as building shelving, breaking down lumber, or making precise cuts for furniture.

Pros and Cons

Pros:

- Highly durable alloy steel construction.

- Tungsten carbide teeth offer long-lasting sharpness.

- Versatile for a range of wood crosscutting tasks.

- Thin kerf allows for efficient material removal and less strain on the saw.

Cons:

- 40 teeth might not provide an ultra-fine finish compared to higher-tooth blades.

- Some users may find it more suitable for course cutting than truly fine finishing despite the description.

Customer Reviews

Customer Review: “Solid course blade for my chop saw, miter saw. This blade is my go to for chopping 2×4’s with ease. Making those cuts for a giant wall of storage shelving. Its a solid workhorse at a very reasonable price point.I even use this for making those inlay cuts for furniture made out of hardware store l”

Customer Review: “This blade is holding up very will after using it for the last 2 days cutting up a bunch of 2.4’s. The teeth are still sharp and should last for a while. This is a good buy for the price but won’t hold up as good as the more expensive ones. It said it is for fine finishing but not so, see below fo”

3. ANGELSWORD 12-Inch Miter Saw Blade 2-Pack: 40T Ripping and 60T Fine Woodworking.

The ANGELSWORD 12-Inch Miter Saw Blade 2-Pack offers incredible value by providing two specialized blades for different woodworking tasks. You get a 40-tooth blade for efficient ripping and a 60-tooth blade for finer woodworking, both featuring a thin kerf and tungsten carbide teeth for smooth, clean cuts and extended durability. This set is a fantastic way to cover your bases without breaking the bank.

Key Features That Stand Out

- ✓ Versatile 2-Pack: Includes a 40T blade for ripping and a 60T blade for fine finish crosscutting.

- ✓ Optimal Dimensions: 12-inch diameter with a 1-inch arbor and 0.106-inch kerf for compatibility.

- ✓ High-Quality Construction: Features a robust plate and thin kerf for fast, clean, and smooth cuts.

- ✓ Durable Carbide Teeth: Tungsten carbide teeth offer excellent wear and heat resistance, ensuring a longer lifespan.

Why We Recommend It

This 2-pack from ANGELSWORD is an outstanding choice for anyone looking to equip their miter saw for various woodworking tasks on a budget. Having both a ripping and a finer finishing blade allows you to switch seamlessly between different applications, providing excellent versatility and performance for the price.

Best For

This blade set is best for woodworkers who need versatility for both aggressive ripping and smooth fine finish work, especially those on a budget or setting up a new workshop.

Pros and Cons

Pros:

- Exceptional value with two blades for different applications.

- Provides clean and smooth cuts for both ripping and fine woodworking.

- Durable tungsten carbide teeth ensure longevity.

- Thin kerf minimizes material waste and reduces saw strain.

Cons:

- May not match the absolute precision of premium single-purpose blades.

- The 60T blade, while good, might not be as fine as a 100+ tooth blade for ultra-delicate work.

Customer Reviews

Customer Review: “I use many top end 10” blades for my finish carpentry saws but needed a cheaper blade for a 12” compound saw I plucked from a trash bin at a construction site that needed a new electrical cord and some TLC.These blades are running very true and are staying sharp after moderate use for framing and P”

Customer Review: “These saw blades are a great value. I am a contractor who builds a lot of decks and the blades are holding up well. Will definitely buy them again.”

4. Freud Thin Kerf Sliding Compound Miter Saw Blade with Premium Tico Hi-Density Carbide Crosscuttin…

The Freud Thin Kerf Sliding Compound Miter Saw Blade is a premium choice for serious woodworkers who demand exceptional cut quality and longevity. Featuring Freud’s exclusive TiCo Hi-Density Carbide blend, this blade is specifically designed for crosscutting, ensuring maximum performance and edge retention. Its negative hook angle and thin kerf make it incredibly user-friendly and efficient, even for less powerful saws.

Key Features That Stand Out

- ✓ Negative Hook Angle: Engineered to gently push the workpiece down and against the fence, ensuring safer and more precise cuts.

- ✓ Premium TiCo Carbide Blend: Freud’s proprietary high-density carbide blend maximizes cutting performance, durability, and edge life.

- ✓ Thin Kerf Design: Removes less material, requiring less horsepower and producing equally good results with less effort.

- ✓ Perma-Shield Coating: Non-stick coating resists heat, corrosion, and pitch buildup, enhancing performance and blade life.

Why We Recommend It

Freud blades are synonymous with quality, and this model is no exception. We recommend it for its superior engineering, which results in remarkably clean cuts and extended blade life. The negative hook angle adds a layer of safety and control, making it a favorite among those who prioritize precision and consistency in their woodworking projects.

Best For

This blade is best for professional woodworkers, cabinet makers, and serious hobbyists who need top-tier precision and durability for fine crosscutting, trim work, and intricate joinery with a sliding compound miter saw.

Pros and Cons

Pros:

- Delivers exceptionally clean and accurate cuts on various woods.

- Premium TiCo carbide blend ensures long-lasting sharpness and durability.

- Negative hook angle enhances safety and cutting control.

- Thin kerf reduces material waste and power consumption.

Cons:

- Higher price point compared to entry-level blades.

- Primarily designed for crosscutting, less ideal for dedicated ripping.

Customer Reviews

Customer Review: “I purchased this Freud Industrial class blade from Amazon for use in my Ridgid sliding compound miter saw some time back, and it has worked in a championship way. It cuts clean, although it is no speed demon, and one thing it can do well is cut shallow dado grooves with no tear out. I did this when “

Customer Review: “This is one of the best blades I have put on yet. Clean cuts and little to no effort getting through the wood. I haven’t seen any burning yet from the crosscuts I’ve been making on hard and soft wood. Highly recommend. Will be staying with this company for the foreseeable future.”

5. WEN BL1080 10-Inch 80-Tooth Carbide-Tipped Ultra-Fine Finish Professional Woodworking Saw Blade f…

The WEN BL1080 10-Inch 80-Tooth Carbide-Tipped Ultra-Fine Finish Saw Blade is engineered for those who demand exceptionally clean and smooth cuts in a variety of wood types. With its 80 carbide-tipped teeth and ultra-thin kerf, this blade reduces splintering and delivers a professional-grade finish, making it a reliable choice for detailed woodworking tasks. It’s designed to maintain consistent performance up to 6000 RPM, perfect for both hard and softwoods.

Key Features That Stand Out

- ✓ High Tooth Count: 80 carbide-tipped teeth provide an ultra-fine finish, minimizing tear-out.

- ✓ Optimal Dimensions: 10-inch diameter with a 5/8-inch arbor, compatible with most standard miter saws.

- ✓ Ultra-Thin Kerf: A 1/10-inch (2.4 mm) kerf ensures clean cuts and efficient material removal.

- ✓ Versatile Performance: Capable of slicing through both hardwoods and softwoods effectively, rated up to 6000 RPM.

Why We Recommend It

We recommend the WEN BL1080 for its excellent balance of performance and affordability when it comes to fine finishing. It’s a fantastic upgrade for standard miter saw blades, offering a significantly cleaner cut for trim, cabinetry, and other woodworking projects where precision is key. Its durability ensures it will be a staple in your workshop for a long time.

Best For

This blade is best for hobbyists and professionals alike who prioritize ultra-fine finishes on both hard and softwoods, making it ideal for detailed cabinetry, molding, and furniture making.

Pros and Cons

Pros:

- Delivers exceptional ultra-fine finishes with minimal splintering.

- Carbide-tipped teeth offer enhanced durability and longevity.

- Ultra-thin kerf provides efficient cutting and less material waste.

- Effective on both hard and softwoods.

Cons:

- 80 teeth might be slower for very aggressive cuts or ripping.

- May require a bit more careful handling due to the fine teeth.

Customer Reviews

Customer Review: “This is a decent 80 tooth carbide blade at a very attractive price. I’m not making fine furniture for a living, and am not overly concerned about minimizing cutting time, tooth marks or sanding time, so very expensive blades are largely wasted on me. And having said that, this blade delivers a very”

Customer Review: “Works great, still going, sharp, strong great quality for the price. Cuts accurately for 1/8 the cost od DW junk”

Complete Buying Guide for Miter Saw Blade For Woodworking

Essential Factors We Consider

Choosing the best miter saw blade for woodworking means looking beyond just the price tag. We carefully consider several key factors to ensure you get a blade that perfectly matches your needs. First, the tooth count is crucial: fewer teeth (24-40) are great for fast, rough cuts and ripping, while more teeth (60-120+) provide smoother, cleaner finishes for crosscutting and delicate work. The kerf thickness also matters; thin kerf blades cut faster and require less power, ideal for underpowered saws, but might be less stable. Thicker kerf blades are more stable and durable, suitable for heavy-duty use. We also evaluate the carbide grade, as higher-quality carbide tips retain their sharpness longer, and special coatings can reduce friction and heat buildup, extending blade life and improving cut quality. Lastly, the hook angle affects how aggressively the blade cuts – a negative hook angle is safer for miter saws as it pushes the wood down, while a positive hook angle is more aggressive.

Budget Planning

When it comes to purchasing the best miter saw blade for woodworking, it’s easy to get lost in the sea of options. For basic DIY projects or occasional use, a mid-range blade (think $30-$60) often provides a good balance of performance and value. These blades are typically durable enough for common tasks and offer satisfactory cut quality. However, if you’re a professional woodworker or tackling intricate projects where precision is paramount, investing in a premium blade ($70-$150+) is a wise decision. These higher-end blades often feature superior carbide, advanced coatings, and specialized tooth geometries that deliver exceptional cut quality and significantly longer life, saving you money on replacements and sharpening in the long run. Remember, a cheap blade can often lead to frustration, poor results, and potentially costly material waste, so consider your usage frequency and project requirements when setting your budget.

Final Thoughts

Ultimately, the “best” miter saw blade depends on your specific woodworking applications. For general-purpose work, a good quality 60-80 tooth blade can handle most tasks effectively. For dedicated fine finish work, especially on expensive hardwoods or veneers, a 100-120 tooth blade will provide the pristine edges you desire. Always prioritize carbide quality and blade design features like thin kerf or specialized hook angles based on your saw and the type of cuts you’ll be making most often. Investing in the right blade is an investment in the quality of your work and the longevity of your tools.

Frequently Asked Questions

Q: What is the ideal tooth count for a miter saw blade for fine woodworking?

A: For fine woodworking, particularly crosscutting and trim work, an 80-tooth to 120-tooth blade is ideal. These higher tooth counts create very smooth, clean cuts with minimal tear-out, which is crucial for visible joints and finishes.

Q: Can I use a regular circular saw blade on my miter saw?

A: While some circular saw blades might fit the arbor, it’s generally not recommended. Miter saw blades are specifically designed with appropriate tooth configurations (like negative hook angles) and kerf thicknesses for the precision and safety required in miter cutting. Using the wrong blade can lead to poor cuts, kickback, or damage to your saw.

Q: What’s the difference between a thin kerf and a thick kerf blade?

A: A thin kerf blade removes less material (typically 3/32″ or less), which means less waste and less strain on your saw’s motor. This is great for underpowered saws or when conserving material. Thick kerf blades (typically 1/8″) are more robust, provide greater stability, and are less prone to deflection, making them suitable for heavy-duty tasks and more powerful saws.

Q: How often should I sharpen my miter saw blade?

A: The frequency depends on how often you use the blade and the types of wood you cut. Generally, a carbide-tipped blade can last for many hours of cutting. You’ll know it’s time for sharpening when cuts become rougher, the blade starts burning the wood, or you notice increased effort is needed to push the saw through the material. Professional sharpening is usually recommended for carbide blades.

Q: Are all carbide tips on blades the same quality?

A: No, carbide tips vary significantly in quality. Higher-quality carbide, often referred to as “premium” or “micro-grain” carbide, is denser and more resistant to wear and impact, meaning it stays sharper longer. Brands like Freud with their TiCo carbide blend use specific formulations to enhance durability and cutting performance. Cheaper blades often use lower-grade carbide that dulls faster.

Choosing the best miter saw blade for woodworking is a decision that significantly impacts the quality and efficiency of your projects. By understanding the nuances of tooth count, kerf, carbide quality, and hook angle, you can confidently select a blade that elevates your craftsmanship. We hope this guide has provided valuable insights to help you make an informed choice and achieve flawless results in your next woodworking endeavor. Happy cutting!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.