Welding is an energy-intensive process that plays a crucial role in various industries, from manufacturing to construction. As energy costs continue to rise and environmental concerns grow, it’s becoming increasingly important for welders and fabrication shops to find ways to reduce their energy consumption.

This guide will explore various strategies and techniques to save energy when welding, helping you to reduce costs, improve efficiency, and minimize your environmental impact.

Image by megmeet-welding

Energy Consumption in Welding

Before diving into energy-saving techniques, it’s essential to understand how energy is consumed during the welding process.

Primary Sources of Energy Consumption

- Arc Generation: The electrical energy required to create and maintain the welding arc.

- Melting Metal: Energy used to melt the base metal and filler material.

- Equipment Operation: Power consumed by welding machines, cooling systems, and auxiliary equipment.

- Idle Time: Energy wasted when equipment is powered on but not actively welding.

Factors Affecting Energy Consumption

- Welding Process: Different welding methods have varying energy requirements.

- Material Properties: The type and thickness of the metal being welded affect energy needs.

- Equipment Efficiency: Older or poorly maintained equipment may consume more energy.

- Welding Parameters: Factors like amperage, voltage, and arc length influence energy use.

Choosing Energy-Efficient Welding Equipment

One of the most effective ways to save energy when welding is to invest in modern, energy-efficient equipment.

Inverter-Based Welding Machines

Inverter technology has revolutionized welding power sources, offering significant energy savings compared to older transformer-based machines. Inverter welders:

- Are more efficient in converting input power to welding power

- Have lower idle power consumption

- Offer better control over welding parameters, reducing waste

- Are typically smaller and lighter, making them more portable

When considering an upgrade to inverter technology, factor in the potential energy savings over the life of the equipment to justify the initial investment.

Multi-Process Welding Machines

Multi-process welders can perform various welding techniques (e.g., MIG, TIG, Stick) using a single power source. This versatility can lead to energy savings by:

- Reducing the need for multiple machines

- Minimizing idle time when switching between processes

- Optimizing power usage for each welding method

Energy-Efficient Auxiliary Equipment

Don’t overlook the energy consumption of auxiliary equipment such as:

- Wire feeders

- Cooling systems

- Fume extractors

Look for energy-efficient models with features like automatic shut-off or power-saving modes when not in use.

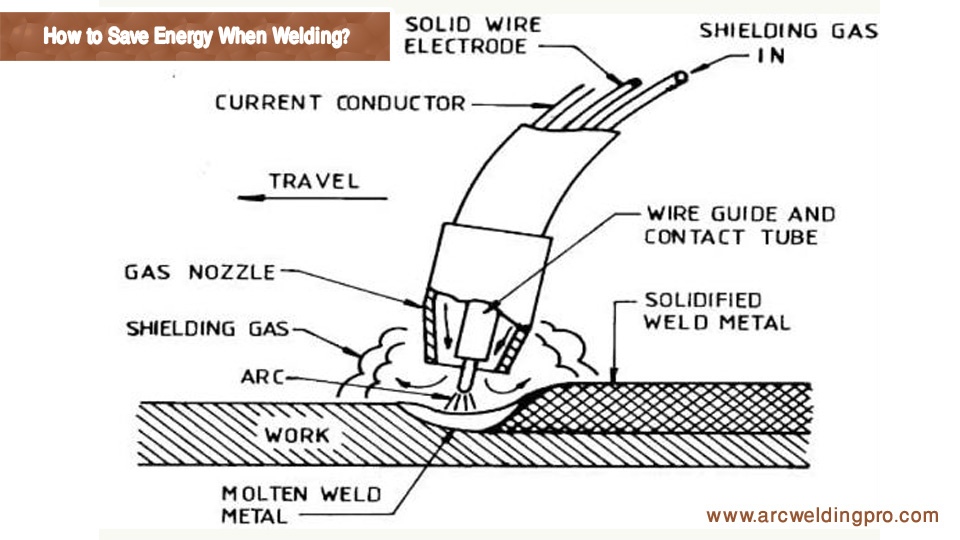

Optimizing Welding Processes for Energy Efficiency

The choice of welding process and how it’s implemented can significantly impact energy consumption.

Image by canadianmetalworking

Selecting the Right Welding Process

Different welding processes have varying energy requirements. Consider the following:

- MIG (GMAW) welding is generally more energy-efficient for thicker materials and longer welds.

- TIG (GTAW) welding, while precise, can be less energy-efficient due to slower speeds.

- Stick (SMAW) welding is often less energy-efficient but may be necessary for certain applications.

Choose the most appropriate process for each job, balancing energy efficiency with weld quality requirements.

Implementing Advanced Welding Techniques

Modern welding technologies can offer energy savings through improved efficiency:

- Pulsed MIG welding can reduce heat input and increase deposition rates.

- Cold Metal Transfer (CMT) processes use less heat, reducing energy consumption.

- Narrow gap welding techniques can minimize the amount of filler material needed, saving energy in both welding and material production.

Optimizing Welding Parameters

Fine-tuning welding parameters can lead to significant energy savings:

- Use the lowest acceptable amperage and voltage for the job.

- Minimize arc time by optimizing travel speed and technique.

- Reduce arc length to improve energy transfer efficiency.

- Use synergic welding programs when available to automatically optimize parameters.

Improving Welding Efficiency and Reducing Waste

Efficient welding practices not only save energy but also improve welding productivity and reduce material waste.

Proper Joint Preparation

Investing time in proper joint preparation can pay off in energy savings:

- Ensure clean, properly aligned joints to minimize rework.

- Use appropriate joint designs to reduce the volume of weld metal required.

- Consider using backing strips or ceramic backing to improve efficiency on single-pass welds.

Minimizing Overwelding

Overwelding is a common source of energy waste:

- Use weld sizing charts to determine the appropriate weld size for the application.

- Train welders to recognize and avoid over welding.

- Implement quality control measures to ensure welds meet, but don’t exceed, requirements.

Reducing Rework and Repairs

Rework and repairs consume additional energy and materials:

- Implement robust quality control procedures to catch issues early.

- Provide ongoing training to improve welder skills and reduce defects.

- Use welding procedure specifications (WPS) to ensure consistent, high-quality welds.

Image fsmdirect

Maximizing Equipment Efficiency

Proper maintenance and operation of welding equipment can lead to significant energy savings.

Regular Maintenance

Well-maintained equipment operates more efficiently:

- Clean or replace air filters regularly to ensure proper cooling.

- Check and tighten electrical connections to reduce resistance and heat generation.

- Lubricate moving parts as recommended by the manufacturer.

- Replace worn consumables (contact tips, nozzles) to maintain arc stability and efficiency.

Proper Cable Management

Welding cables can be a source of energy loss:

- Use the shortest possible cable lengths to minimize resistance.

- Choose cables with appropriate ampacity for the welding current.

- Regularly inspect cables for damage and replace as needed.

- Keep cables untangled and avoid sharp bends to reduce resistance.

Minimizing Idle Time

Reducing equipment idle time can lead to substantial energy savings:

- Implement automatic shut-off features for equipment not in use.

- Train welders to turn off machines during breaks or between jobs.

- Use power management systems to monitor and control energy use across multiple welding stations.

Implementing Energy-Efficient Facility Practices

Energy savings in welding extend beyond the welding process itself to the entire facility.

Optimizing Ventilation and Fume Extraction

Welding fume extraction systems can consume significant energy:

- Use local exhaust ventilation instead of general ventilation where possible.

- Implement variable speed drives on extraction systems to match airflow to demand.

- Regularly clean and maintain filtration systems to ensure efficient operation.

Lighting and HVAC Considerations

The welding environment can impact overall energy consumption:

- Use energy-efficient LED lighting in welding areas.

- Implement zoned lighting controls to illuminate only active work areas.

- Optimize HVAC systems for welding environments, considering heat generated by welding processes.

Compressed Air Systems

Many welding operations rely on compressed air:

- Regularly check for and repair air leaks.

- Use appropriately sized compressors for the facility’s needs.

- Implement heat recovery systems to utilize waste heat from air compressors.

Leveraging Technology for Energy Management

Modern technology offers powerful tools for managing and reducing energy consumption in welding operations.

Welding Data Monitoring Systems

Advanced monitoring systems can provide valuable insights into energy use:

- Track energy consumption per weld or per project.

- Identify inefficiencies and opportunities for improvement.

- Set and monitor energy usage targets.

Predictive Maintenance

Use data analytics to predict maintenance needs:

- Identify equipment that may be consuming excess energy due to wear or malfunction.

- Schedule maintenance proactively to maintain peak efficiency.

- Track energy consumption trends to spot gradual declines in efficiency.

Simulation and Virtual Welding

Leverage simulation tools to optimize processes before actual welding:

- Use virtual welding systems for training to reduce material and energy waste.

- Simulate welding processes to optimize parameters without consuming real materials or energy.

- Plan complex welding projects virtually to minimize rework and energy waste.

Training and Employee Engagement

Effective energy-saving strategies rely on the engagement and skills of welding personnel.

Energy Awareness Training

Educate welders and support staff on energy conservation:

- Provide training on the impact of welding practices on energy consumption.

- Share energy-saving goals and progress with the team.

- Encourage suggestions for energy-saving improvements from staff.

Skill Development

Invest in ongoing skill development for welders:

- Train welders in energy-efficient welding techniques.

- Provide opportunities for welders to learn about new, energy-efficient technologies.

- Implement certification programs that include energy efficiency as a key component.

Incentive Programs

Consider implementing incentive programs to encourage energy-saving behaviors:

- Recognize and reward individuals or teams that achieve energy-saving targets.

- Implement friendly competitions focused on energy efficiency.

- Share the benefits of energy savings with employees through bonuses or improved facilities.

Conclusion

Saving energy when welding requires a comprehensive approach that considers equipment, processes, facility management, and human factors. By implementing the strategies outlined in this guide, welding operations can significantly reduce their energy consumption, leading to cost savings, improved efficiency, and a reduced environmental impact.

Energy-saving initiatives should be an ongoing process. Regularly review and update your energy-saving strategies, stay informed about new technologies and techniques, and continue to engage your team in the pursuit of greater energy efficiency. With dedication and the right approach, substantial energy savings are achievable in any welding operation.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.