Submerged Arc Welding (SAW) is a highly efficient and productive welding process widely used in various industries, including shipbuilding, pressure vessel manufacturing, and heavy structural steelwork. This advanced welding technique offers unique advantages in terms of weld quality, productivity, and operator safety. In this guide, we’ll explore the intricacies of submerged arc welding, its working principles, components, and applications.

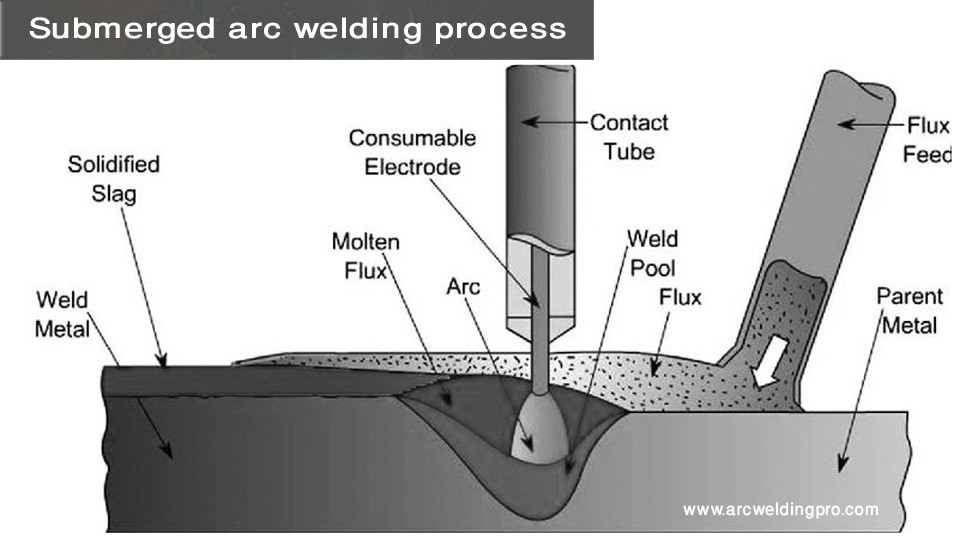

Image by weldingpros

Basics of Submerged Arc Welding

Submerged Arc Welding is an arc welding process that uses a continuously fed electrode and a separate granular flux to protect the weld area. The term “submerged” refers to the fact that the arc is completely covered by a layer of flux during the welding process, making it invisible to the naked eye.

Key Components of SAW

To understand how submerged arc welding works, it’s essential to familiarize yourself with its main components:

- Electrode: A continuous wire that serves as both the filler material and one of the electrodes in the arc.

- Flux: A granular material that covers the welding area, protecting it from atmospheric contamination and stabilizing the arc.

- Power Source: Provides the electrical energy necessary for the welding process.

- Wire Feeder: Continuously supplies the electrode wire to the welding area.

- Flux Hopper: Stores and dispenses the granular flux over the weld area.

- Welding Head: Houses the contact tip for the electrode and guides the flux onto the weld joint.

- Travel Mechanism: Moves the welding head along the joint, either manually or automatically.

Submerged Arc Welding Process

Now that we’ve covered the basic components, let’s dive into how the submerged arc welding process actually works.

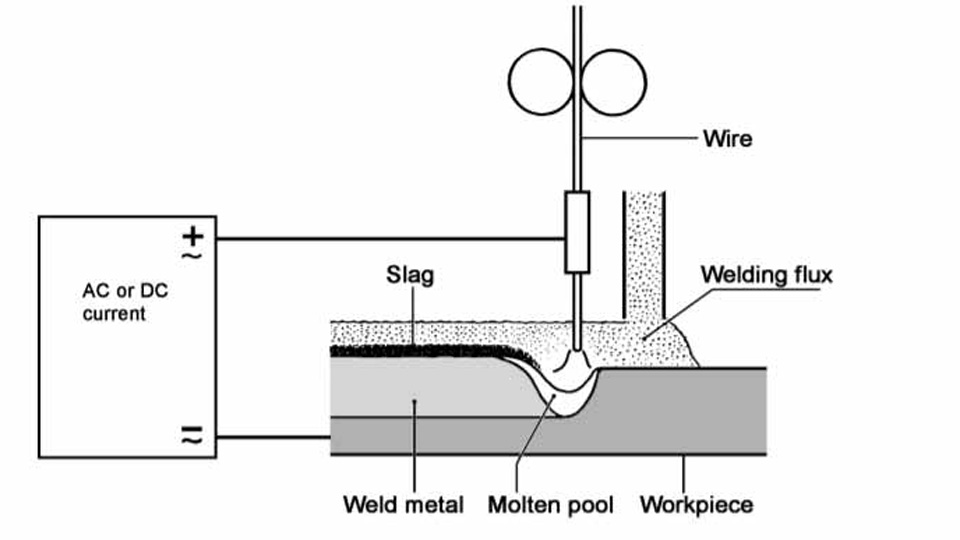

Image by westermans

Arc Initiation

The process begins with the initiation of an electric arc between the continuously fed electrode wire and the workpiece. This arc is struck beneath a layer of granular flux, which is deposited ahead of the welding head.

Flux Melting and Slag Formation

As the arc generates intense heat, it melts both the electrode wire and the surrounding flux. The molten flux forms a protective slag layer over the weld pool, shielding it from atmospheric contamination and helping to shape the weld bead.

Metal Transfer and Weld Pool Formation

The heat from the arc melts the electrode wire, which then transfers to the workpiece, forming a weld pool. The molten metal from the base material also contributes to this pool. The high current used in SAW allows for deep penetration and efficient melting of the base metal.

Solidification and Slag Removal

As the welding head moves along the joint, the weld pool behind it begins to solidify. The slag layer on top of the weld also cools and solidifies, often separating from the weld bead naturally as it cools. Any remaining slag can be easily removed after welding.

Flux Recovery

Unused flux that hasn’t melted during the welding process can be recovered and reused, making SAW an economical choice for large-scale welding operations.

Unique Aspects of Submerged Arc Welding

Several features make submerged arc welding stand out from other welding processes:

Invisible Arc

One of the most distinctive characteristics of SAW is that the arc is completely covered by the flux layer. This feature offers several advantages:

- Improved operator safety by eliminating the risk of arc eye

- Reduced need for personal protective equipment

- Minimal welding fumes and spatter, creating a cleaner work environment

High Deposition Rates

SAW is known for its high deposition rates, which can be attributed to:

- The use of high welding currents (often up to 2000 amperes)

- Continuous wire feeding

- The ability to use larger diameter electrodes

These factors allow SAW to deposit more weld metal in less time compared to many other welding processes.

Deep Penetration

The submerged arc welding process achieves deep penetration into the base metal, which is beneficial for welding thick materials. This deep penetration is due to:

- High heat input from the powerful arc

- The insulating effect of the flux layer, which concentrates heat in the weld zone

- The pressure exerted by the arc on the weld pool

Power Sources and Electrical Characteristics

Submerged arc welding can be performed using either direct current (DC) or alternating current (AC) power sources, each with its own characteristics and applications.

Image by cruxweld

Direct Current (DC) Welding

DC welding is the most common choice for SAW, offering:

- Stable arc characteristics

- Good penetration when using electrode positive (DCEP) polarity

- Higher deposition rates when using electrode negative (DCEN) polarity

Alternating Current (AC) Welding

AC welding in SAW is often used for:

- Reducing arc blow in magnetic materials

- Balancing penetration and deposition rate

- Multiple wire systems to prevent magnetic interference between arcs

Flux Types and Their Role

The flux used in submerged arc welding plays a crucial role in the process. There are several types of fluxes, each with specific characteristics and applications:

Fused Fluxes

These fluxes are produced by melting raw materials and then crushing the cooled mass. Fused fluxes offer:

- Consistent performance

- Low moisture absorption

- Good arc stability

Bonded Fluxes

Bonded fluxes are made by binding powdered ingredients with a liquid binder. They provide:

- Greater flexibility in composition

- Ability to introduce alloying elements into the weld metal

- Often lower cost compared to fused fluxes

Agglomerated Fluxes

These fluxes are similar to bonded fluxes but use a different manufacturing process. They offer:

- Excellent control over flux composition

- Good moisture resistance

- Consistent performance

The choice of flux depends on factors such as the base metal composition, desired weld properties, and specific application requirements.

Electrode Types and Selection

Electrodes for submerged arc welding come in various forms:

Solid Wire Electrodes

The most common type, solid wire electrodes are available in a range of diameters and compositions to suit different applications.

Cored Wire Electrodes

These electrodes contain a metal sheath filled with powdered materials, allowing for the addition of alloying elements or flux components.

Strip Electrodes

Used for specialized applications, strip electrodes offer high deposition rates and are often used for surfacing or cladding operations.

Selecting the right electrode depends on factors such as the base metal composition, required mechanical properties, and the chosen flux type.

Applications of Submerged Arc Welding

Submerged arc welding finds extensive use in various industries due to its high productivity and quality welds. Some common applications include:

Shipbuilding

SAW is widely used in shipyards for:

- Joining thick steel plates for ship hulls

- Welding longitudinal and circumferential seams in large diameter pipes

- Fabricating structural components

Pressure Vessel Manufacturing

The deep penetration and high quality welds make SAW ideal for:

- Welding thick-walled vessels

- Joining domed ends to cylindrical shells

- Longitudinal and circumferential seams in large tanks

Heavy Structural Steelwork

In the construction of large structures, SAW is used for:

- Fabricating large beams and columns

- Joining thick plates in bridge construction

- Manufacturing wind turbine towers

Pipeline Construction

SAW plays a crucial role in pipeline welding, particularly for:

- Longitudinal seam welding of large diameter pipes

- Double-sided welding of pipe sections in the field

Automotive Industry

In automotive manufacturing, SAW is employed for:

- Welding wheel rims

- Fabricating truck frames

- Joining components in heavy equipment

Image by deprest

Advantages and Limitations of Submerged Arc Welding

Like any welding process, SAW has its strengths and limitations. Understanding these can help in determining whether it’s the right choice for a particular application.

Advantages

- High Productivity: SAW offers high deposition rates and can be easily automated, leading to increased productivity.

- Excellent Weld Quality: The process produces high-quality welds with good mechanical properties and minimal defects.

- Deep Penetration: SAW can achieve deep penetration, making it suitable for welding thick materials.

- Improved Work Environment: The submerged arc eliminates visible arc radiation and reduces fumes and spatter.

- Flux Recovery: Unused flux can be recovered and reused, reducing material waste.

- Versatility: SAW can be used for a wide range of materials and thicknesses, from about 5mm upwards.

Limitations

Positional Limitations: SAW is primarily limited to flat and horizontal welding positions due to the fluid nature of the weld pool and flux.

Equipment Complexity: The process requires specialized equipment, including flux handling systems, which can be more complex than some other welding methods.

Initial Cost: The equipment for SAW can be more expensive than that for simpler welding processes.

Not Suitable for Thin Materials: SAW is generally not practical for materials thinner than about 5mm due to the high heat input.

Limited Visibility: The submerged arc means that the operator cannot directly observe the weld pool, requiring precise setup and control.

Conclusion

Submerged arc welding is a powerful and efficient welding process that has revolutionized many industries requiring high-volume, high-quality welds. Its unique approach of using a granular flux to shield the arc and weld pool offers numerous advantages in terms of weld quality, productivity, and operator safety.

While it may not be suitable for every welding application due to its positional limitations and equipment requirements, SAW remains an indispensable tool in the fabrication of large structures, pressure vessels, ships, and many other products requiring robust, high-quality welds.

As welding technology continues to advance, we can expect to see further innovations in submerged arc welding, potentially expanding its capabilities and applications. For engineers, welders, and fabricators working on large-scale projects, understanding the principles and applications of submerged arc welding is crucial for making informed decisions about welding processes and achieving optimal results in their work.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.