Welding heat input is a crucial parameter in the welding process that significantly influences the quality and properties of the resulting weld. Accurately calculating and controlling heat input is essential for welders, engineers, and fabricators to produce high-quality welds that meet specific requirements.

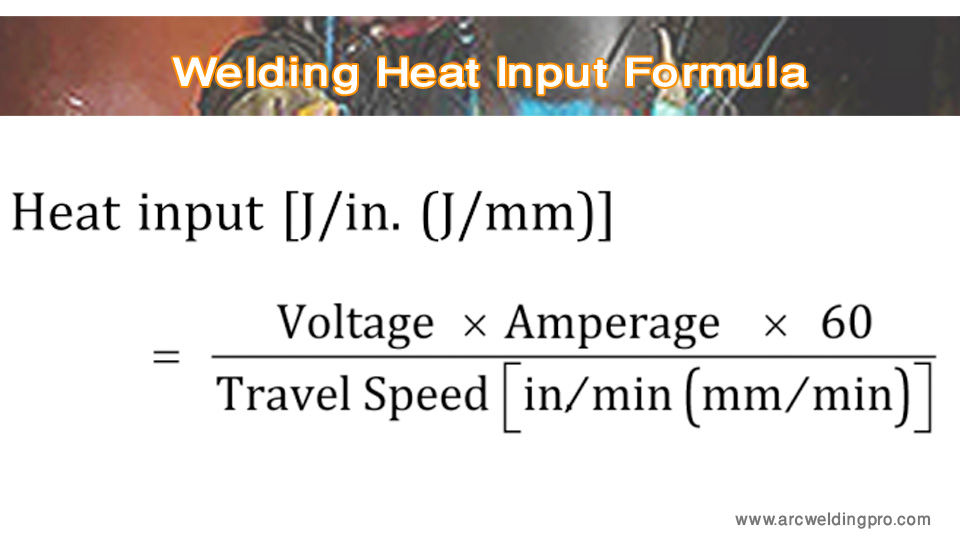

Welding Heat Input Formula

Basic Heat Input Formula

The most commonly used formula for calculating welding heat input is:

Heat Input = (Voltage ? Amperage ? 60) / (Travel Speed ? 1000)

Where:

- Heat Input is in kJ/in or J/mm

- Voltage is in volts (V)

- Amperage is in amperes (A)

- Travel Speed is in inches per minute (in/min) or millimeters per minute (mm/min)

Advanced Heat Input Formula

For more accurate calculations, a process efficiency factor can be included:

Heat Input = (Voltage ? Amperage ? 60 ? Efficiency) / (Travel Speed ? 1000)

Typical efficiency factors for common welding processes:

- SMAW (Stick welding): 0.7-0.8

- GMAW (MIG welding): 0.7-0.8

- GTAW (TIG welding): 0.6-0.7

- SAW (Submerged Arc Welding): 0.9-0.99

What is Welding Heat Input?

Welding heat input is defined as the amount of energy transferred per unit length of weld. It represents the thermal energy delivered to the base material during the welding process. Heat input is typically expressed in units of joules per millimeter (J/mm) or kilojoules per inch (kJ/in).

Importance of Heat Input

Proper control of heat input is crucial for several reasons:

- Influences weld bead geometry

- Affects mechanical properties of the weld

- Determines the microstructure of the weld and heat-affected zone (HAZ)

- Impacts susceptibility to weld defects

- Controls residual stresses and distortion

Factors Affecting Heat Input

Voltage

Higher voltage increases arc length, which can lead to a wider weld bead and increased heat input.

Amperage

Higher amperage increases the amount of heat generated, directly affecting heat input.

Travel Speed

Slower travel speeds result in higher heat input, as more energy is deposited per unit length of weld.

Welding Process Efficiency

Different welding processes have varying efficiencies in transferring heat to the base material.

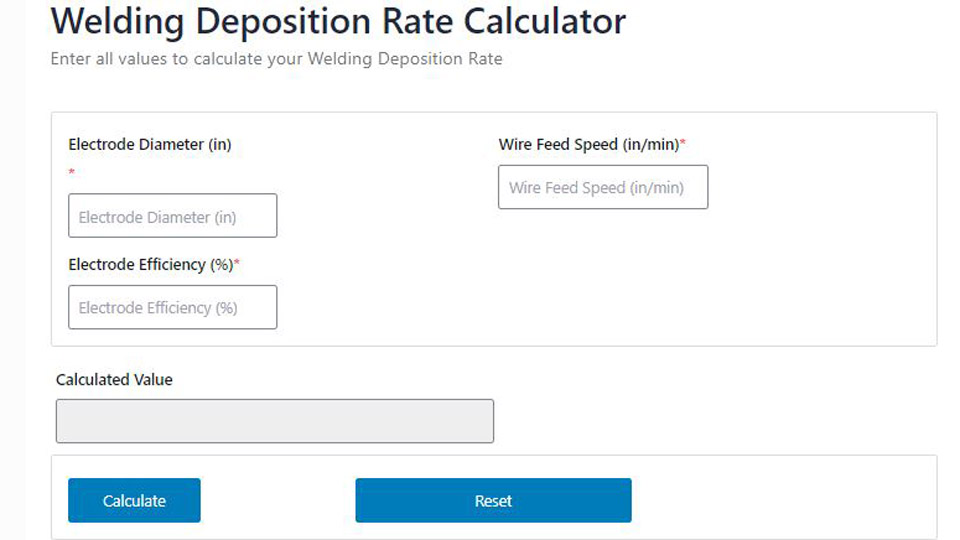

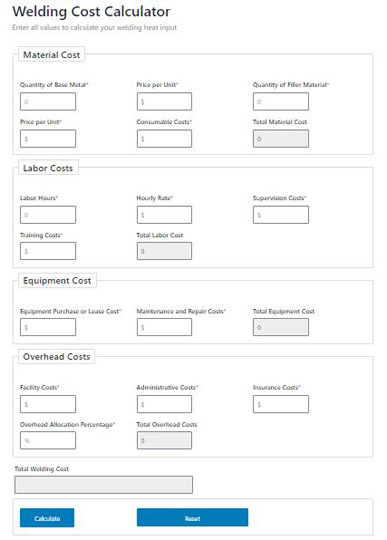

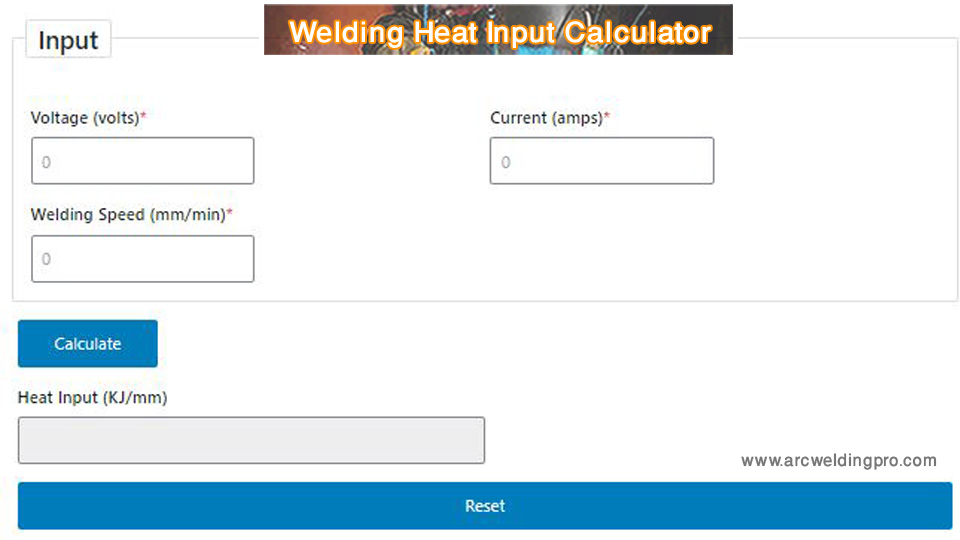

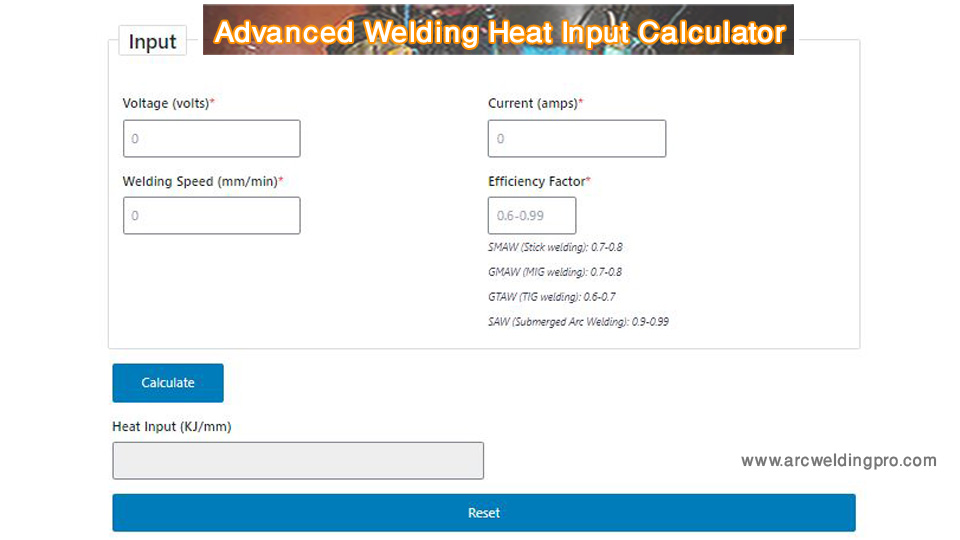

Welding Heat Input Calculator

Purpose of Heat Input Calculators

Welding heat input calculators are tools designed to simplify the process of determining heat input for various welding applications. These calculators typically take input parameters such as voltage, amperage, travel speed, and sometimes process efficiency to compute the heat input quickly and accurately.

Types of Heat Input Calculators

- Online Calculators: Web-based tools that allow users to input parameters and receive instant results.

- Mobile Apps: Smartphone applications that provide heat input calculations on-the-go.

- Spreadsheet-based Calculators: Excel or Google Sheets templates that perform heat input calculations.

- Integrated Calculators: Features built into welding power sources or data acquisition systems.

Benefits of Using Heat Input Calculators

- Quick and accurate calculations

- Reduced risk of human error in manual calculations

- Easy comparison of different welding parameters

- Ability to save and track heat input data for multiple welds

- Some advanced calculators may provide additional information like cooling rates or HAZ size estimates

Interpreting Heat Input Values

Low Heat Input

Typically considered as values below 1 kJ/mm (25 kJ/in)

Characteristics:

- Faster cooling rates

- Smaller HAZ

- Higher strength and hardness

- Potential for incomplete fusion or lack of penetration

Moderate Heat Input

Generally ranges from 1-2 kJ/mm (25-50 kJ/in)

Characteristics:

- Balanced cooling rates

- Moderate HAZ size

- Good balance of strength and ductility

- Suitable for many general welding applications

High Heat Input

Usually considered as values above 2 kJ/mm (50 kJ/in)

Characteristics:

- Slower cooling rates

- Larger HAZ

- Potential for reduced strength and increased ductility

- May lead to excessive grain growth in some materials

Optimizing Heat Input for Different Materials

Carbon and Low-Alloy Steels

- Moderate heat input is generally preferred

- Typical range: 0.8-2.5 kJ/mm (20-60 kJ/in)

- Higher heat inputs may be used for thicker sections

Stainless Steels

- Lower heat input is often preferred to maintain corrosion resistance

- Typical range: 0.5-1.5 kJ/mm (12-38 kJ/in)

- Austenitic grades may tolerate higher heat inputs than ferritic or martensitic grades

Aluminum Alloys

- Lower heat input is generally preferred due to high thermal conductivity

- Typical range: 0.3-1.2 kJ/mm (8-30 kJ/in)

- Heat-treatable alloys may require stricter control of heat input

High-Strength Steels

- Careful control of heat input is critical

- Typical range: 0.5-1.5 kJ/mm (12-38 kJ/in)

- Lower heat inputs are often preferred to maintain strength and toughness

Keep records of heat input calculations for quality control and process optimization purposes.

Heat Input Ranges for Different Materials

| Material | Low Heat Input (kJ/mm) | Moderate Heat Input (kJ/mm) | High Heat Input (kJ/mm) |

|---|---|---|---|

| Carbon Steel | 0.5 – 1.0 | 1.0 – 2.0 | 2.0 – 3.0 |

| Stainless Steel | 0.3 – 0.8 | 0.8 – 1.5 | 1.5 – 2.5 |

| Aluminum Alloys | 0.3 – 0.6 | 0.6 – 1.0 | 1.0 – 1.5 |

| High-Strength Steel | 0.3 – 0.7 | 0.7 – 1.2 | 1.2 – 2.0 |

Best Practices for Using Heat Input Calculators

Verify Input Parameters

Ensure that voltage, amperage, and travel speed values are accurate and representative of the actual welding conditions.

Consider Process Efficiency

Use appropriate efficiency factors for the welding process being used to obtain more accurate heat input values.

Account for Preheat

Some advanced calculators allow for the input of preheat temperature, which can affect the overall heat input and cooling rates.

Use Consistent Units

Ensure that all input parameters use consistent units (metric or imperial) to avoid calculation errors.

Validate Results

Cross-check calculator results with manual calculations or other calculators to ensure accuracy.

Document and Track

Conclusion

Welding heat input calculators and formulas are essential tools for welders, engineers, and fabricators to ensure proper control of the welding process. By accurately calculating and managing heat input, it’s possible to optimize weld quality, mechanical properties, and overall structural integrity of welded components.

Understanding the factors that influence heat input and how to interpret the calculated values is crucial for producing high-quality welds across a wide range of materials and applications. By leveraging heat input calculators and following best practices, welding professionals can streamline their processes, improve consistency, and achieve better welding outcomes.

As welding technology continues to advance, we can expect to see more sophisticated heat input calculators integrated into welding equipment and data management systems. These tools will provide even greater insights into the welding process, allowing for real-time adjustments and optimizations to produce superior welds with enhanced efficiency and reliability.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.