Rivets are essential fasteners used in various industries to join materials together permanently. These simple yet effective tools have been used for centuries, evolving to meet the demands of modern manufacturing and construction. In this guide, we’ll explore the different types of rivets available and their specific uses, helping you understand which rivet is best suited for your particular application.

Image by engineeringlearn

What is the Rivets

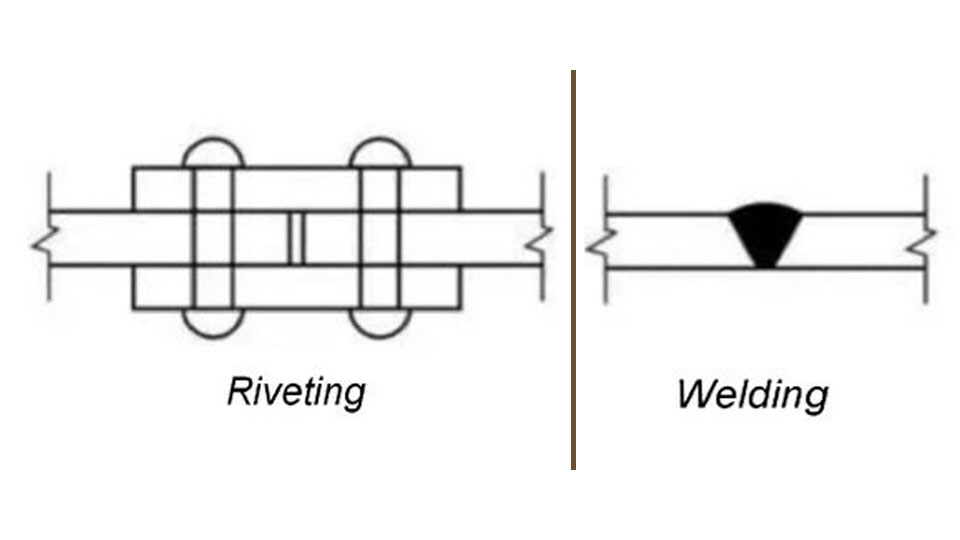

Before diving into the various types of rivets, it’s important to understand what a rivet is and how it works. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a head on one end. The rivet is inserted through aligned holes in the materials to be joined, and the tail end is then deformed (usually by hammering or pressing) to create a second head, securing the materials together.

Basic Components of a Rivet

- Head: The pre-formed end of the rivet that remains visible after installation.

- Shank: The cylindrical body of the rivet that passes through the materials being joined.

- Tail: The end of the rivet that is deformed during installation to create the second head.

Types of Rivets

There are several types of rivets available, each designed for specific applications and materials. Let’s explore the most common types:

Solid Rivets

Solid rivets are the oldest and most traditional type of rivet. They consist of a solid shaft with a pre-formed head on one end.

Characteristics:

- Made from a single piece of metal

- Require access to both sides of the joint for installation

- Provide excellent strength and reliability

Uses:

- Aircraft construction

- Shipbuilding

- Heavy machinery

- Structural steel work

Advantages:

- Extremely strong and durable

- Suitable for high-stress applications

- Resistant to vibration loosening

Disadvantages:

- Require specialized tools for installation

- Not suitable for blind applications (where only one side is accessible)

Blind Rivets (Pop Rivets)

Blind rivets, also known as pop rivets, are one of the most versatile and widely used types of rivets. They can be installed from one side of the workpiece, making them ideal for applications where access to the back side is limited or impossible.

Characteristics:

- Consist of a hollow rivet body and a mandrel

- Can be installed using a hand-operated or pneumatic rivet gun

- Available in various materials and sizes

Uses:

- Automotive body work

- HVAC systems

- Electronics enclosures

- General sheet metal work

Advantages:

- Easy to install

- Suitable for blind applications

- Available in a wide range of materials and sizes

Disadvantages:

- Generally not as strong as solid rivets

- The mandrel may fall out after installation in some applications

Tubular Rivets

Tubular rivets are similar to solid rivets but have a hollow shaft. This design makes them easier to deform during installation, requiring less force to create the second head.

Characteristics:

- Hollow shaft with a pre-formed head

- Easier to install than solid rivets

- Available in various materials, including soft metals like copper and brass

Uses:

- Leather goods manufacturing

- Bookbinding

- Light-duty sheet metal work

- Textile industry

Advantages:

- Require less force to install compared to solid rivets

- Suitable for softer materials

- Can provide a decorative finish

Disadvantages:

- Not as strong as solid rivets

- May not be suitable for high-stress applications

Split Rivets

Split rivets, also known as bifurcated rivets, have a split tail that spreads apart when driven, creating a secure fastening.

Characteristics:

- Shaft is split at the tail end

- Can be installed with a hammer or press

- Often used with softer materials

Uses:

- Leather goods

- Textile products

- Wood joining

- Light-duty applications

Advantages:

- Easy to install

- Suitable for softer materials

- Provide a decorative finish

Disadvantages:

- Limited strength compared to other rivet types

- Not suitable for high-stress applications

Drive Rivets

Drive rivets are a type of blind rivet that can be installed using a hammer. They have a pin protruding from the head that, when struck, expands the rivet body.

Characteristics:

- Self-setting rivet with a pin in the head

- Can be installed with a hammer

- Available in various materials

Uses:

- Automotive trim

- Signage

- Light-duty sheet metal work

- Plastic assemblies

Advantages:

- Simple installation without specialized tools

- Suitable for blind applications

- Can be used with a variety of materials

Disadvantages:

- Limited strength compared to other rivet types

- May not provide a flush finish

- Structural Rivets

Structural rivets are high-strength fasteners designed for use in critical load-bearing applications. They are similar to solid rivets but are typically larger and made from stronger materials.

Characteristics:

- Large diameter and high-strength materials

- Require specialized installation equipment

- Provide excellent shear and tensile strength

Uses:

- Bridge construction

- High-rise buildings

- Heavy machinery

- Industrial equipment

Advantages:

- Extremely high strength and durability

- Suitable for critical structural applications

- Resistant to vibration and fatigue

Disadvantages:

- Require specialized installation equipment

- More expensive than standard rivets

- Not suitable for thin or delicate materials

Comparison of Rivet Types

To help you choose the right rivet for your application, here’s a comparison table of the different types of rivets:

| Rivet Type | Strength | Ease of Installation | Blind Application | Material Versatility | Cost |

|---|---|---|---|---|---|

| Solid Rivets | High | Difficult | No | Limited | Low |

| Blind Rivets | Medium | Easy | Yes | High | Medium |

| Tubular Rivets | Low-Medium | Medium | No | Medium | Low |

| Split Rivets | Low | Easy | No | High | Low |

| Drive Rivets | Low-Medium | Easy | Yes | Medium | Low |

| Structural Rivets | Very High | Difficult | No | Limited | High |

Factors to Consider When Choosing Rivets

Selecting the right type of rivet for your application is crucial for ensuring a secure and long-lasting joint. Here are some key factors to consider:

Material Compatibility

The rivet material should be compatible with the materials being joined to prevent galvanic corrosion. Common rivet materials include:

- Aluminum

- Steel

- Stainless Steel

- Copper

- Brass

Joint Strength Requirements

Consider the load and stress the joint will be subjected to. High-stress applications may require solid or structural rivets, while lighter loads can be handled by blind or tubular rivets.

Accessibility

If you only have access to one side of the joint, blind rivets or drive rivets are your best options. For applications where both sides are accessible, solid or tubular rivets may be more suitable.

Aesthetics

In visible applications, consider the appearance of the rivet head. Some rivets, like countersunk rivets, can provide a flush finish, while others may have a decorative head design.

Installation Equipment

Different rivet types require different installation tools. Consider the availability and cost of the necessary equipment when choosing your rivet type.

Environmental Factors

Consider the environment in which the riveted joint will be used. Factors such as temperature, humidity, and exposure to chemicals can affect the choice of rivet material and type.

Rivet Installation Techniques

Proper installation is crucial for ensuring the strength and reliability of riveted joints. Here are some general guidelines for installing rivets:

Hole Preparation

- Ensure holes are properly aligned and sized for the rivet

- Deburr holes to prevent interference with rivet seating

Rivet Selection

- Choose the appropriate rivet length based on the total thickness of the materials being joined

- Select the correct rivet diameter for the hole size

Installation

- For solid rivets: Use a pneumatic rivet gun or manual hammer and bucking bar

- For blind rivets: Use a hand-operated or pneumatic rivet gun

- For drive rivets: Use a hammer to drive the pin into the rivet body

Quality Check

- Inspect the installed rivet for proper seating and head formation

- Check for any gaps or looseness in the joint

Conclusion

Rivets are versatile and reliable fasteners that play a crucial role in many industries. By understanding the different types of rivets available and their specific uses, you can make informed decisions about which rivet is best suited for your particular application.

Whether you’re working on a DIY project or a large-scale industrial application, choosing the right rivet can ensure the strength, durability, and longevity of your joined materials.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.