In the world of structural engineering and metal fabrication, choosing the right method for joining materials is crucial for ensuring the integrity, durability, and efficiency of structures. While riveted and bolted connections have been used for centuries, welded connections have gained significant popularity in modern construction and manufacturing.

This blog post will explore the numerous advantages that welded connections offer over their riveted or bolted counterparts, helping you understand why welding has become the preferred method in many applications.

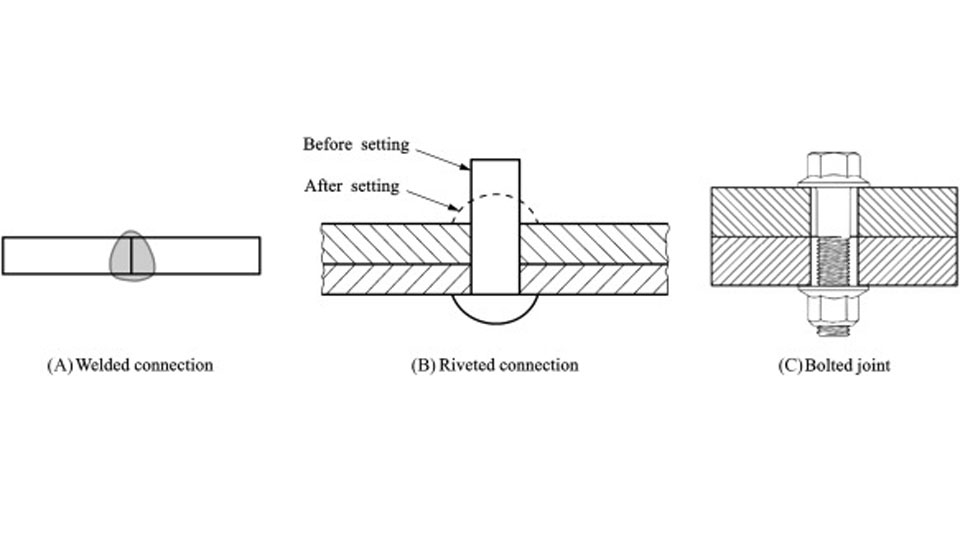

Image by sciencedirect

Welded, Riveted, and Bolted Connections

Before delving into the advantages of welded connections, let’s briefly define each joining method:

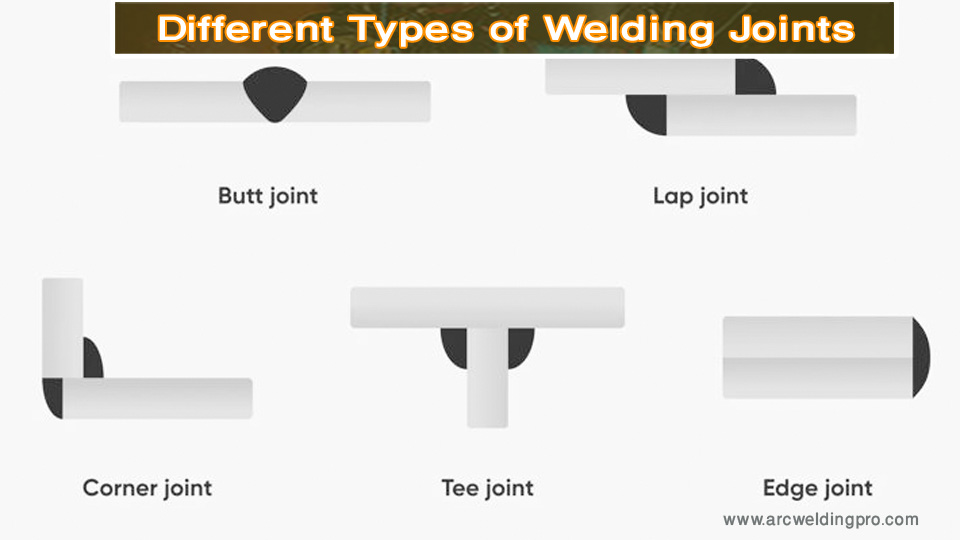

Welded Connections

Welding is a process that uses heat to melt and fuse materials together, creating a strong, permanent bond. There are various welding techniques, including arc welding, MIG welding, and TIG welding, each suited for different applications.

Riveted Connections

Riveting involves using metal fasteners (rivets) to join materials. The rivet is inserted through aligned holes in the materials and then deformed to create a permanent connection.

Bolted Connections

Bolted connections use threaded fasteners (bolts and nuts) to join materials. These connections can be easily disassembled and are considered non-permanent.

Advantages of Welded Connections

Now, let’s explore the key advantages that welded connections offer over riveted or bolted connections:

Superior Strength and Rigidity

One of the most significant advantages of welded connections is their superior strength and rigidity compared to riveted or bolted joints.

Continuous Bond

Welding creates a continuous, uninterrupted bond along the entire joint, distributing stress evenly across the connection. This results in a stronger, more rigid structure that can better withstand various loads and stresses.

Material Fusion

The welding process actually fuses the materials being joined, creating a bond that is often as strong as or even stronger than the base materials themselves. This is in contrast to riveted or bolted connections, which rely on mechanical fastening and friction to hold materials together.

Weight Reduction

Welded connections offer significant weight-saving benefits compared to riveted or bolted joints.

Elimination of Fasteners

By eliminating the need for rivets, bolts, nuts, and washers, welded connections reduce the overall weight of the structure. This weight reduction can be substantial in large-scale projects, leading to improved efficiency and reduced material costs.

Optimized Design

Welding allows for more streamlined and efficient designs, as there’s no need to accommodate overlapping plates or extra material for bolt holes. This optimization further contributes to weight reduction and material savings.

Improved Aesthetics

Welded connections often provide a cleaner, more aesthetically pleasing appearance compared to riveted or bolted joints.

Seamless Finish

Properly executed welds can create a smooth, seamless finish that blends with the surrounding material. This is particularly advantageous in applications where appearance is important, such as in architectural structures or consumer products.

Design Flexibility

Welding offers greater design flexibility, allowing for more complex and visually appealing shapes and structures that might be difficult or impossible to achieve with riveted or bolted connections.

Enhanced Leak and Corrosion Resistance

Welded connections provide superior protection against leaks and corrosion compared to riveted or bolted joints.

Continuous Seal

The continuous nature of a welded joint creates an effective seal against liquids and gases, making it ideal for applications requiring watertight or airtight connections.

Reduced Corrosion Points

Welded joints eliminate the crevices and gaps typically found in riveted or bolted connections, reducing potential points of corrosion initiation. This can significantly extend the lifespan of the structure, especially in harsh environments.

Cost-Effectiveness in Large-Scale Production

While the initial setup costs for welding equipment can be higher, welded connections often prove more cost-effective in large-scale production scenarios.

Reduced Labor Costs

Once set up, welding processes can be highly automated, reducing labor costs and increasing production efficiency. This is particularly advantageous in high-volume manufacturing environments.

Fewer Components

The elimination of fasteners and associated components (like washers and lock nuts) simplifies inventory management and reduces overall material costs in large-scale production.

Versatility in Material Joining

Welding offers greater versatility in joining different types and thicknesses of materials compared to riveting or bolting.

Joining Dissimilar Materials

Advanced welding techniques allow for the joining of dissimilar metals, which can be challenging or impossible with riveted or bolted connections.

Thickness Variations

Welding can easily accommodate joints between materials of varying thicknesses, providing more design flexibility and efficiency in material usage.

Improved Fatigue Resistance

Welded connections generally offer better fatigue resistance compared to riveted or bolted joints.

Stress Distribution

The continuous nature of welded joints allows for more even stress distribution, reducing stress concentrations that can lead to fatigue failure.

Elimination of Fretting

Welded connections eliminate the small movements between joined parts that can occur in bolted or riveted joints under cyclic loading. This fretting can lead to fatigue failure over time.

Space Efficiency

Welded connections often result in more space-efficient designs compared to riveted or bolted joints.

Compact Joints

Welded joints typically require less space than equivalent strength riveted or bolted connections, allowing for more compact and efficient designs.

Reduced Interference

The absence of protruding bolt heads or rivet tails means welded structures can be designed with tighter clearances and less interference with surrounding components.

Welded vs Riveted vs Bolted Connections

To summarize the advantages of welded connections, here’s a comparison table:

| Factor | Welded Connections | Riveted Connections | Bolted Connections |

|---|---|---|---|

| Strength | High | Medium | Medium |

| Weight | Low | High | High |

| Aesthetics | Excellent | Fair | Fair |

| Leak/Corrosion Resistance | Excellent | Fair | Poor |

| Cost-Effectiveness (Large-Scale) | High | Medium | Medium |

| Material Versatility | High | Medium | High |

| Fatigue Resistance | Excellent | Good | Fair |

| Space Efficiency | Excellent | Fair | Poor |

| Disassembly | Difficult | Difficult | Easy |

| Skill Required | High | Medium | Low |

Considerations and Limitations of Welded Connections

While welded connections offer numerous advantages, it’s important to consider their limitations and potential drawbacks:

Skill and Equipment Requirements

Welding requires skilled operators and specialized equipment, which can increase initial costs and training requirements.

Inspection and Quality Control

Ensuring the quality of welded joints often requires more rigorous inspection and testing procedures compared to riveted or bolted connections.

Heat-Affected Zone

The welding process creates a heat-affected zone in the base material, which can alter its properties and potentially weaken the structure if not properly managed.

Difficulty in Disassembly

Welded connections are permanent, making disassembly for maintenance or modification challenging compared to bolted connections.

Environmental Sensitivity

Welding processes can be sensitive to environmental conditions such as wind, moisture, and temperature, which may affect weld quality in field applications.

Conclusion

Welded connections offer significant advantages over riveted or bolted connections in many applications, including superior strength, weight reduction, improved aesthetics, enhanced leak and corrosion resistance, and cost-effectiveness in large-scale production. These benefits have made welding the preferred joining method in numerous industries, from automotive manufacturing to construction of large-scale structures.

The choice between welded, riveted, or bolted connections should always be based on the specific requirements of each project. Factors such as load conditions, material properties, environmental factors, maintenance needs, and cost considerations all play a role in determining the most suitable joining method.

As welding technology continues to advance, we can expect to see even greater adoption of welded connections across various industries. Innovations in welding processes, materials, and automation are likely to further enhance the advantages of welded connections, making them an increasingly attractive option for engineers and designers seeking to create strong, efficient, and durable structures.

Understanding the advantages and limitations of each joining method empowers professionals to make informed decisions, ensuring the optimal balance of strength, efficiency, and cost-effectiveness in their designs and constructions.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.