Soldering is a crucial process in various industries, from electronics manufacturing to plumbing and jewelry making. It involves joining two or more metal items together using a filler metal (solder) that has a lower melting point than the base metals being joined. While soldering is a fundamental skill, it requires precision and care to achieve strong, reliable connections.

One of the most common issues that can compromise the quality of a soldered joint is overheating. In this guide will explore the effects of overheating on soldering joints, its causes, and how to prevent it.

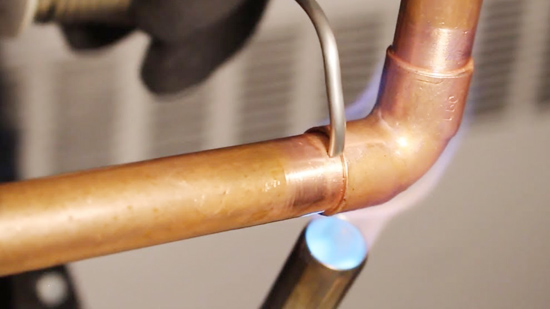

Image by reddit

Soldering Process

Before delving into the effects of overheating, it’s essential to understand the basics of the soldering process.

Key Components of Soldering

- Base metals: The materials being joined

- Solder: The filler metal used to create the joint

- Flux: A substance that helps clean the metal surfaces and promote better solder flow

- Heat source: Typically a soldering iron or torch

Ideal Soldering Process

In an ideal soldering scenario, the following steps occur:

- The base metals are cleaned and prepared.

- Flux is applied to the joint area.

- The joint is heated to the appropriate temperature.

- Solder is applied and melts, flowing into the joint.

- The heat is removed, allowing the solder to cool and solidify.

- A strong, conductive joint is formed.

Defining Overheating in Soldering

Overheating occurs when the temperature applied during the soldering process exceeds the optimal range for the materials involved. This can happen due to various factors, including:

- Using a soldering iron or heat source that’s too hot

- Applying heat for too long

- Poor heat control techniques

- Inadequate understanding of the materials’ properties

Temperature Ranges for Common Soldering Applications

| Application | Optimal Temperature Range | Overheating Threshold |

|---|---|---|

| Electronics (Lead-free) | 315?C – 370?C (600?F – 700?F) | >400?C (752?F) |

| Electronics (Leaded) | 300?C – 350?C (572?F – 662?F) | >380?C (716?F) |

| Plumbing (Copper) | 200?C – 250?C (392?F – 482?F) | >300?C (572?F) |

| Jewelry (Silver) | 650?C – 750?C (1202?F – 1382?F) | >800?C (1472?F) |

Effects of Overheating on Soldered Joints

Overheating can have several detrimental effects on the quality and reliability of soldered joints. Let’s explore these effects in detail.

Weakened Joint Strength

One of the most significant impacts of overheating is the reduction in the mechanical strength of the soldered joint.

Causes of Weakened Joints:

- Excessive growth of intermetallic compounds

- Formation of brittle phases in the solder

- Degradation of the base metal’s properties

Consequences:

- Reduced load-bearing capacity

- Increased susceptibility to mechanical failure

- Shorter lifespan of the soldered connection

Poor Electrical Conductivity

In electronic applications, overheating can significantly impact the electrical properties of the joint.

Factors Affecting Conductivity:

- Oxidation of the solder and base metals

- Formation of high-resistance intermetallic layers

- Voids and gaps in the solder joint

Results:

- Increased electrical resistance

- Signal integrity issues in high-frequency applications

- Potential for intermittent connections

Thermal Damage to Surrounding Components

Overheating doesn’t just affect the joint itself; it can also damage nearby components and materials.

Potential Damages:

- Melting or warping of plastic components

- Delamination of printed circuit boards

- Damage to heat-sensitive electronic components

Long-term Effects:

- Reduced reliability of the entire assembly

- Increased risk of system failures

- Higher repair and maintenance costs

Excessive Solder Consumption

Overheating can lead to the use of more solder than necessary, which has several negative consequences.

Issues with Excess Solder:

- Formation of solder bridges in electronic circuits

- Increased material costs

- Potential for cold joints due to uneven cooling

Implications:

- Quality control problems

- Increased rework and inspection time

- Higher production costs

Flux Degradation

Flux plays a crucial role in the soldering process, and overheating can severely impact its effectiveness.

Effects on Flux:

- Premature evaporation or burning of flux

- Reduced cleaning and oxide-removal capabilities

- Formation of harmful residues

Consequences:

- Poor solder wetting and flow

- Increased risk of oxidation and contamination

- Potential for corrosion in the long term

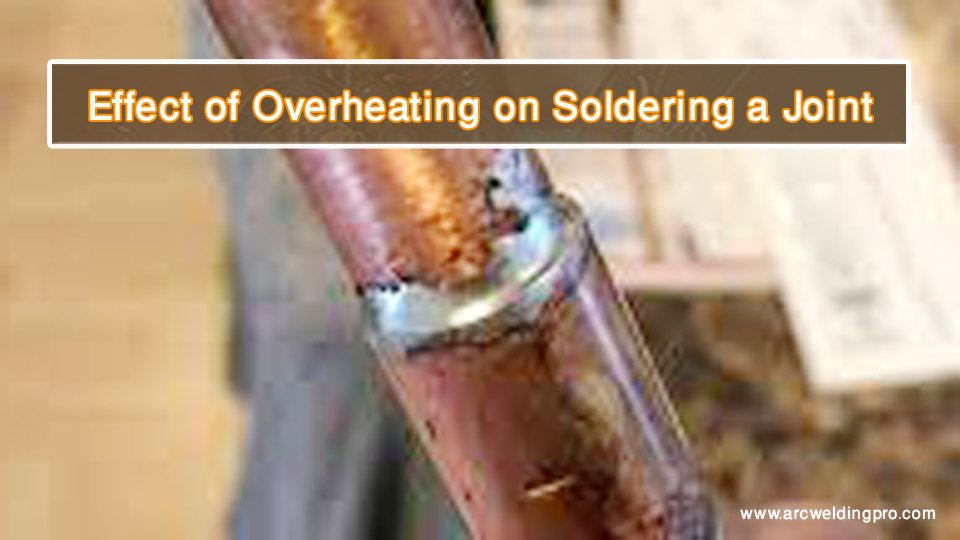

Identifying Overheated Solder Joints

Recognizing the signs of an overheated solder joint is crucial for quality control and troubleshooting. Here are some visual indicators:

Visual Cues of Overheated Joints:

- Dull, grainy appearance instead of a smooth, shiny surface

- Excessive solder flow or “flooding”

- Discoloration of the base metals or PCB

- Visible burning or charring of flux residues

- Solder spatter or “solder balls” around the joint

- Deformed or melted plastic components near the joint

Microscopic Indicators:

Under magnification, overheated joints may show:

- Enlarged grain structures in the solder

- Voids or gas pockets within the joint

- Excessive growth of intermetallic layers

- Cracks or fissures in the solder or base metals

Preventing Overheating During Soldering

To avoid the negative effects of overheating, it’s essential to implement proper soldering techniques and controls.

Temperature Control

Maintaining the correct temperature is crucial for successful soldering.

Best Practices:

- Use temperature-controlled solering irons

- Regularly calibrate and maintain soldering equipment

- Select the appropriate temperature for the materials and solder being used

- Allow sufficient time for the soldering iron to reach and stabilize at the desired temperature

Proper Heat Application Techniques

How you apply heat to the joint can significantly impact the risk of overheating.

Recommended Techniques:

- Apply heat to the largest thermal mass first

- Use the appropriate tip size for the joint

- Move the heat source continuously to distribute heat evenly

- Remove the heat source as soon as the solder flows and wets the joint

Time Management

Controlling the duration of heat application is as important as controlling the temperature.

Time Management Strategies:

- Practice to develop a sense of timing for different joint sizes and materials

- Use a timer or count seconds mentally when soldering

- Pre-tin components when possible to reduce soldering time

- Work efficiently to minimize heat exposure

Proper Material Selection

Choosing the right materials for your soldering project can help prevent overheating issues.

Material Considerations:

- Select solder with an appropriate melting point for your application

- Use flux formulated for your specific soldering needs

- Choose base metals and components with compatible thermal properties

- Consider using heat sinks for sensitive components

Education and Training

Proper education and training are essential for preventing overheating and other soldering issues.

Training Topics:

- Understanding of material properties and thermal behavior

- Proper use and maintenance of soldering equipment

- Recognition of good and bad solder joints

- Troubleshooting techniques for common soldering problems

Effects of Proper Soldering vs Overheating

To better understand the impact of overheating, let’s compare the characteristics of properly soldered joints with those that have been overheated.

| Characteristic | Proper Soldering | Overheated Joint |

|---|---|---|

| Appearance | Smooth, shiny surface | Dull, grainy, or discolored |

| Joint Strength | High mechanical strength | Weakened, prone to failure |

| Electrical Conductivity | Low resistance, good conductivity | Increased resistance, poor conductivity |

| Solder Flow | Controlled, even wetting | Excessive flow, potential bridging |

| Flux Action | Effective cleaning and oxide removal | Degraded flux, potential residues |

| Surrounding Components | Unaffected | Potential thermal damage |

| Long-term Reliability | High reliability, long lifespan | Reduced reliability, potential for early failure |

Remediation of Overheated Solder Joints

In cases where overheating has occurred, it may be necessary to remediate the affected joints. Here are some steps to address overheated solder joints:

Assessment

- Visually inspect the joint for signs of overheating

- Use magnification to identify microscopic issues

- Test the joint’s electrical properties if applicable

Removal of Damaged Joint

- Use a solder wick or desoldering pump to remove the overheated solder

- Clean the area thoroughly to remove any flux residues or oxidation

Preparation for Resoldering

- Inspect the base metals for damage and replace if necessary

- Apply fresh flux to the joint area

Careful Resoldering

- Use proper temperature control and heat application techniques

- Apply new solder to create a fresh joint

- Monitor the process closely to avoid repeating the overheating issue

Quality Control

- Inspect the new joint visually and electrically

- Perform any necessary testing to ensure joint integrity

Importance of Proper Heat Management in Soldering

Overheating during the soldering process can have severe and far-reaching consequences on the quality, reliability, and performance of soldered joints. From weakened mechanical strength and poor electrical conductivity to damage to surrounding components, the effects of overheating can compromise the integrity of entire systems and lead to costly failures.

By understanding the causes and effects of overheating, implementing proper soldering techniques, and maintaining strict temperature control, technicians and manufacturers can significantly reduce the risk of overheating-related issues. Proper training, equipment maintenance, and quality control procedures are essential for consistently producing high-quality soldered joints.

Soldering is both a science and an art. While following best practices and guidelines is crucial, developing a feel for proper heat application through practice and experience is equally important. By mastering the delicate balance of heat, time, and material properties, you can create strong, reliable soldered joints that stand the test of time.

As technology continues to advance and miniaturization trends persist, the importance of precise soldering techniques will only grow. Stay informed about new developments in soldering technology, materials, and best practices to ensure that your soldering skills remain sharp and your joints remain strong.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.