Ultrasonic welding is a fast, efficient, and widely used method of joining materials, particularly thermoplastics and some metals. This technique uses high-frequency ultrasonic vibrations to generate heat through friction, causing the materials to fuse without the need for external heat or adhesives.

While ultrasonic welding offers many benefits, it also has limitations that need to be considered depending on the application. We will dive into the advantages and disadvantages of ultrasonic welding, examining how does ultrasonic welding works and where it excels or falls short.

Image by folienvorschub

How Ultrasonic Welding Works

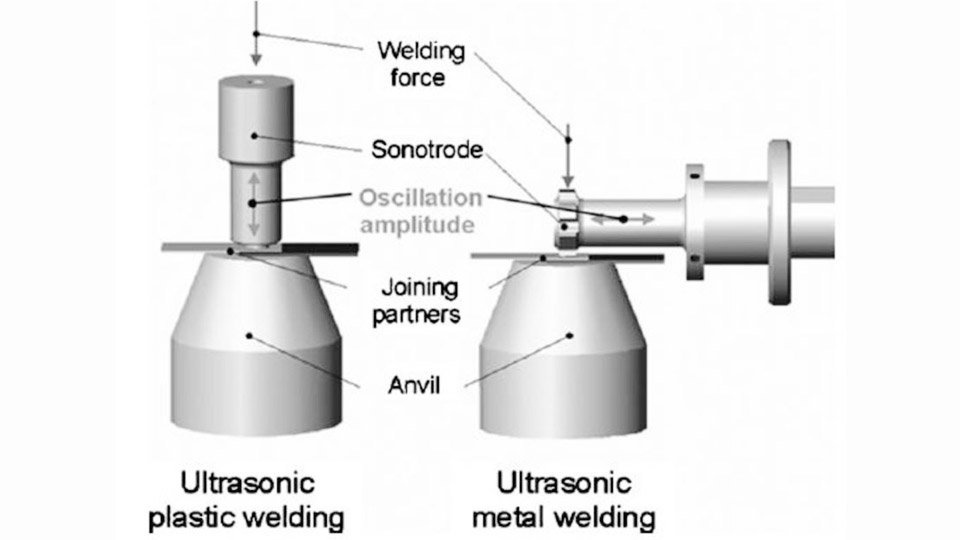

Ultrasonic welding operates by converting electrical energy into high-frequency mechanical vibrations. These vibrations are transmitted through a tool called a sonotrode, which applies pressure and delivers energy to the materials being joined. The friction generated by the ultrasonic waves causes localized heating at the interface of the materials, resulting in a solid-state weld without melting the materials entirely.

The process is quick, often taking just seconds, and can be used for a wide range of applications, from small electronics and medical devices to automotive parts and packaging.

Advantages of Ultrasonic Welding

Fast and Efficient

One of the most significant advantages of ultrasonic welding is its speed. The entire process typically takes just a few seconds, making it ideal for high-volume production environments. Unlike traditional welding methods that require time for heating, cooling, or curing, ultrasonic welding creates a bond almost instantly, allowing manufacturers to increase production rates.

Clean and Eco-Friendly

Ultrasonic welding does not require additional materials such as adhesives, solvents, or fasteners. This eliminates the need for potentially harmful chemicals, making it an environmentally friendly process. Because the process generates minimal waste and does not produce fumes, it creates a cleaner and safer working environment.

No External Heat Required

Unlike traditional welding techniques, which rely on high temperatures to melt the materials, ultrasonic welding generates heat through high-frequency vibrations. This eliminates the need for external heat sources, reducing the risk of thermal damage to surrounding materials and components. This feature is especially beneficial when working with heat-sensitive materials, such as electronics and plastics.

Strong, High-Quality Welds

Ultrasonic welding produces strong, reliable bonds without introducing any foreign materials, such as solder or glue. The welds created are of high quality, with minimal distortion or deformation, because the materials are only softened at the contact points rather than melted entirely. This results in welds that are durable and capable of withstanding mechanical stress.

Versatile Applications

Ultrasonic welding can be used for a variety of materials and applications. It is most commonly employed for welding plastics, but it can also be used to join thin metal sheets and composite materials. Industries such as automotive, medical, electronics, and packaging rely on ultrasonic welding for assembling components quickly and efficiently.

Low Energy Consumption

Ultrasonic welding consumes less energy compared to traditional welding methods because it does not require high levels of heat to create the bond. This makes it a cost-effective solution for manufacturers seeking to reduce their energy usage and overall production costs.

Precision and Control

The precision and control offered by ultrasonic welding make it suitable for applications requiring intricate welds. The process can be fine-tuned to achieve the desired weld strength, making it ideal for joining small, delicate components, such as microelectronics and medical devices.

Disadvantages of Ultrasonic Welding

Limited Material Compatibility

While ultrasonic welding works well with thermoplastics and some metals, it is not suitable for all materials. The process is generally ineffective for materials that are too thick, too hard, or have dissimilar properties. Certain metals, ceramics, and composites may not bond well or at all with ultrasonic welding, limiting its use in some industries.

Size and Thickness Limitations

Ultrasonic welding is most effective for small or medium-sized parts, especially those made from thin materials. Larger or thicker components may not receive enough ultrasonic energy to create a strong weld, as the vibrations may not penetrate deeply enough into the material. This limits its applicability for large-scale industrial or structural applications.

High Initial Equipment Cost

Ultrasonic welding equipment is specialized and can be expensive to purchase and maintain. While the process itself is cost-effective in the long run, the initial investment in ultrasonic welding machines and tools can be high. This may pose a barrier for smaller manufacturers or businesses that cannot justify the upfront costs.

Skilled Operator Requirement

Ultrasonic welding requires skilled operators to ensure proper setup and execution of the process. Factors such as material compatibility, weld parameters, and equipment settings must be carefully controlled to achieve optimal results. Training and expertise are essential to maximize the efficiency and quality of the welds, which can add to the operational costs.

Noise Levels

Ultrasonic welding can generate high-frequency noise, particularly when operating at lower frequencies (around 20 kHz). This noise can be disruptive to workers and may require soundproofing or the use of hearing protection in the manufacturing environment. Addressing the noise issue can add complexity and cost to the workspace setup.

Limited Use for Dissimilar Materials

Ultrasonic welding is generally more effective when joining materials of the same or similar properties. When attempting to weld dissimilar materials, the process may not achieve the same level of bond strength, or the materials may not weld at all. This limitation reduces its versatility in applications where different materials need to be joined together.

Equipment Maintenance

Maintaining ultrasonic welding equipment can be challenging. The sonotrode, which delivers the ultrasonic energy, is subject to wear and tear over time, especially when used with harder materials. Regular maintenance and calibration are required to keep the equipment functioning optimally, which can result in additional costs and downtime.

Advantages vs Disadvantages of Ultrasonic Welding

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Speed | Fast welding process, typically taking seconds | Limited to small and thin materials, slower for larger applications |

| Energy Use | Low energy consumption compared to traditional welding | High initial equipment costs |

| Material Usage | No need for adhesives, fasteners, or consumables | Limited material compatibility, especially with metals and composites |

| Weld Quality | Strong, durable welds with minimal distortion | Limited effectiveness with larger, thicker parts |

| Precision | High precision, suitable for delicate and small components | Skilled operator required for optimal results |

| Environmental Impact | Clean and eco-friendly, no harmful fumes or chemicals | Noise levels may require soundproofing and protective equipment |

| Versatility | Can weld a wide range of thermoplastics and thin metals | Limited when welding dissimilar materials |

| Maintenance | Durable welds, less wear on materials | Equipment requires regular maintenance and can experience wear on sonotrodes |

Applications of Ultrasonic Welding

Ultrasonic welding is used in a wide variety of industries due to its versatility, efficiency, and ability to produce high-quality welds. Some of the most common applications include:

Automotive Industry

Ultrasonic welding is widely used in the automotive industry to assemble components such as dashboards, door panels, and electrical systems. It allows manufacturers to create strong, reliable bonds between plastic parts, which are essential for vehicle safety and performance.

Medical Device Manufacturing

In the medical field, ultrasonic welding is used to assemble small, delicate devices such as catheters, blood filters, and surgical instruments. The precision and cleanliness of the process make it ideal for creating medical devices that meet strict hygiene and safety standards.

Electronics Industry

Ultrasonic welding is commonly used in the electronics industry to bond delicate components, such as circuit boards, connectors, and battery packs. The process’s precision and control ensure that electronic devices are assembled with minimal risk of damage or defects.

Packaging Industry

In the packaging industry, ultrasonic welding is employed to seal plastic packaging, such as food containers and medical bags. The process provides strong, airtight seals that protect the contents from contamination or leakage.

Consumer Products

Ultrasonic welding is used in the production of various consumer goods, including toys, household appliances, and sporting equipment. It enables manufacturers to create durable, high-quality products with a clean, finished appearance.

Conclusion

Ultrasonic welding offers numerous advantages, including speed, precision, and eco-friendliness, making it a popular choice for industries such as automotive, medical, electronics, and packaging. Its ability to create strong, high-quality welds without external heat or adhesives provides manufacturers with a clean and efficient method of joining materials.

The process is not without its limitations. High initial equipment costs, material compatibility issues, and size restrictions can present challenges for certain applications. Understanding the advantages and disadvantages of ultrasonic welding is crucial for manufacturers looking to implement this technology effectively and optimize their production processes.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.