Ultrasonic welding technology is a cutting-edge process used to bond materials, particularly thermoplastics and metals, by applying high-frequency ultrasonic vibrations to create a weld. This method is highly efficient and widely adopted in industries that require fast, reliable, and clean joining of components.

The process works without the need for adhesives, fasteners, or external heat, making it an ideal choice for high-precision applications where a strong, durable bond is needed.

In this blog post, we will explore the fundamentals of ultrasonic welding technology, how the process works, its key components, advantages, disadvantages, and its various applications across different industries.

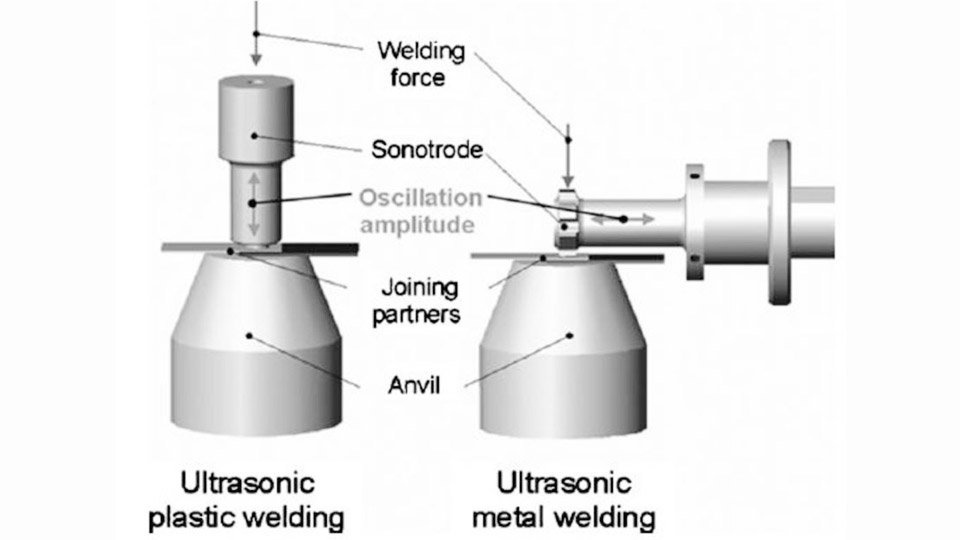

Image by amdmachines

Ultrasonic Welding Technology

Ultrasonic welding is a non-contact, solid-state welding process that uses mechanical vibrations at ultrasonic frequencies, typically ranging between 20 kHz and 40 kHz. The energy generated by these vibrations is transferred to the materials being welded, causing the molecules at the joint to heat up due to friction.

As the materials reach their melting point, the surfaces bond together under pressure, creating a solid weld. The entire process is extremely fast, often taking less than a second to complete.

How Ultrasonic Welding Works

The ultrasonic welding process involves several key steps that ensure the proper transmission of ultrasonic energy, melting, and fusion of the materials being joined.

Key Steps in Ultrasonic Welding

Energy Generation: The ultrasonic generator converts electrical energy into high-frequency mechanical vibrations. These vibrations are then transferred to the transducer.

Vibration Transmission: The transducer converts electrical energy into mechanical vibrations, which are amplified and directed through the sonotrode, a tool that directly contacts the material.

Pressure Application: The sonotrode applies mechanical pressure and delivers ultrasonic energy to the materials. This pressure ensures that the surfaces are in proper contact during the welding process.

Heat Generation: As the ultrasonic vibrations pass through the materials, the friction at the interface generates heat, causing the materials to melt and fuse.

Cooling and Bonding: After the materials have melted and fused, the ultrasonic energy is stopped, and the parts cool, forming a strong and reliable weld.

Key Components of Ultrasonic Welding Technology

Several key components work together to make ultrasonic welding a successful and efficient process. Understanding these components helps provide insight into how the technology works.

Ultrasonic Generator

The ultrasonic generator is the core component responsible for producing the high-frequency electrical signals that are later converted into mechanical vibrations. The generator typically operates at frequencies between 20 kHz and 40 kHz, depending on the application.

Transducer

The transducer is responsible for converting the electrical energy from the generator into mechanical vibrations. It achieves this by using piezoelectric crystals that oscillate when exposed to an electric field, thus producing the desired ultrasonic vibrations.

Booster

The booster amplifies the mechanical vibrations generated by the transducer and helps direct these vibrations toward the sonotrode. Boosters can be adjusted to increase or decrease the amplitude of the vibrations based on the specific requirements of the welding process.

Sonotrode

The sonotrode is the tool that makes direct contact with the materials being welded. It delivers the ultrasonic vibrations and pressure to the materials, ensuring that the necessary energy is transferred for successful welding. Sonotrodes come in various shapes and sizes depending on the application and material being joined.

Anvil

The anvil is a supportive component that holds the materials in place during the welding process. It ensures proper alignment and contact between the materials to create a strong weld.

Advantages of Ultrasonic Welding Technology

Ultrasonic welding technology offers several advantages over traditional welding and joining techniques. Below are some of the key benefits of using ultrasonic welding:

Fast Process

Ultrasonic welding is an extremely fast process, often taking less than a second to complete. This speed is advantageous for high-volume production environments where efficiency is critical.

No Additional Materials Required

Unlike other welding methods that may require adhesives, fasteners, or solder, ultrasonic welding relies solely on mechanical vibrations to create a bond. This reduces material costs and simplifies the production process.

Strong and Reliable Welds

Ultrasonic welding produces high-quality welds that are strong and durable. The resulting bonds are capable of withstanding mechanical stress and are resistant to environmental factors such as moisture, temperature fluctuations, and corrosion.

Clean and Environmentally Friendly

Because ultrasonic welding does not require external heat or chemicals, it is considered a clean and eco-friendly process. The absence of fumes, solvents, or waste makes it safe for operators and reduces the environmental impact.

Versatile

Ultrasonic welding can be used for a wide range of materials, including thermoplastics, metals, and composite materials. Its versatility makes it suitable for many industries, including automotive, electronics, packaging, and medical devices.

Energy-Efficient

Ultrasonic welding consumes less energy compared to other welding methods that rely on high heat or extended bonding times. The energy efficiency of ultrasonic welding contributes to reduced operating costs in manufacturing environments.

Disadvantages of Ultrasonic Welding Technology

While ultrasonic welding offers numerous advantages, there are some limitations and challenges associated with the technology:

Limited to Small or Medium-Sized Parts

Ultrasonic welding is most effective for small or medium-sized parts. Larger components may require more energy than the ultrasonic vibrations can provide, making the process less suitable for large-scale applications.

High Initial Equipment Costs

The initial investment in ultrasonic welding equipment can be high. Specialized machinery, such as ultrasonic generators, transducers, and sonotrodes, can be expensive, which may be a barrier for small businesses or low-volume production.

Material Compatibility

Ultrasonic welding works best with thermoplastics and certain metals. However, it may not be effective for welding materials with vastly different properties or thicknesses. The process is also less effective for materials that are brittle or prone to cracking.

Skilled Operator Requirement

Ultrasonic welding requires skilled operators who understand how to set up the equipment and adjust the parameters for optimal performance. Training and expertise are essential to ensure high-quality welds, which can increase labor costs.

Comparison of Ultrasonic Welding vs Traditional Welding Methods

Ultrasonic welding differs from traditional welding methods in several ways. Below is a comparison of ultrasonic welding and common welding techniques such as arc welding, resistance welding, and laser welding:

| Aspect | Ultrasonic Welding | Traditional Welding Methods |

|---|---|---|

| Process Time | Extremely fast, often less than a second | Slower, with extended heating and cooling times |

| Heat Source | Mechanical vibrations generate frictional heat | External heat sources, such as electric arcs or lasers |

| Material Use | No need for adhesives, fasteners, or consumables | Often requires filler materials, solder, or other bonding agents |

| Energy Efficiency | Low energy consumption | Higher energy consumption due to reliance on external heat |

| Material Compatibility | Best for thermoplastics and thin metals | Suitable for a wide range of materials, including thicker metals |

| Equipment Cost | High initial equipment cost | Varies depending on the method, but often lower initial costs |

| Environmental Impact | Clean and environmentally friendly, no fumes or waste | Can produce harmful fumes, slag, and other waste products |

Applications of Ultrasonic Welding Technology

Ultrasonic welding technology is widely used across various industries due to its speed, precision, and reliability. Below are some of the key applications:

Automotive Industry

Ultrasonic welding is used in the automotive industry to assemble components such as dashboards, door panels, and electrical systems. The process ensures strong and durable bonds for critical parts, making vehicles safer and more reliable.

Electronics Industry

In the electronics industry, ultrasonic welding is used to join small, delicate components such as circuit boards, sensors, and battery packs. The precision and control of the process make it ideal for assembling sensitive electronic devices.

Medical Devices

Ultrasonic welding is widely used in the medical field to produce sterile, reliable devices such as surgical instruments, catheters, and blood filters. The clean and controlled nature of ultrasonic welding makes it suitable for creating devices that meet stringent hygiene and safety standards.

Packaging Industry

Ultrasonic welding is used in the packaging industry to seal plastic containers, pouches, and films. The process ensures that products are securely sealed, protecting them from contamination and extending their shelf life.

Consumer Products

Ultrasonic welding is commonly used to manufacture consumer goods such as household appliances, toys, and sporting equipment. It allows for the efficient assembly of plastic and metal parts, resulting in durable and well-finished products.

Conclusion

Ultrasonic welding technology is a fast, efficient, and versatile process that has transformed the manufacturing industry. By using high-frequency vibrations to create strong, durable bonds without the need for additional materials or external heat, ultrasonic welding offers several advantages, including speed, energy efficiency, and environmental friendliness.

Despite its limitations, such as high initial equipment costs and material compatibility issues, ultrasonic welding remains an essential tool in industries ranging from automotive and electronics to medical devices and packaging. As the technology continues to evolve, ultrasonic welding is likely to become even more integral to modern manufacturing processes.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.