Hot pressure welding is a key process in the manufacturing and repair of various components, especially in industries like automotive, aerospace, and construction. We will delve into the specifics of hot pressure welding equipment, covering its types, applications, advantages, and considerations for selecting the right equipment.

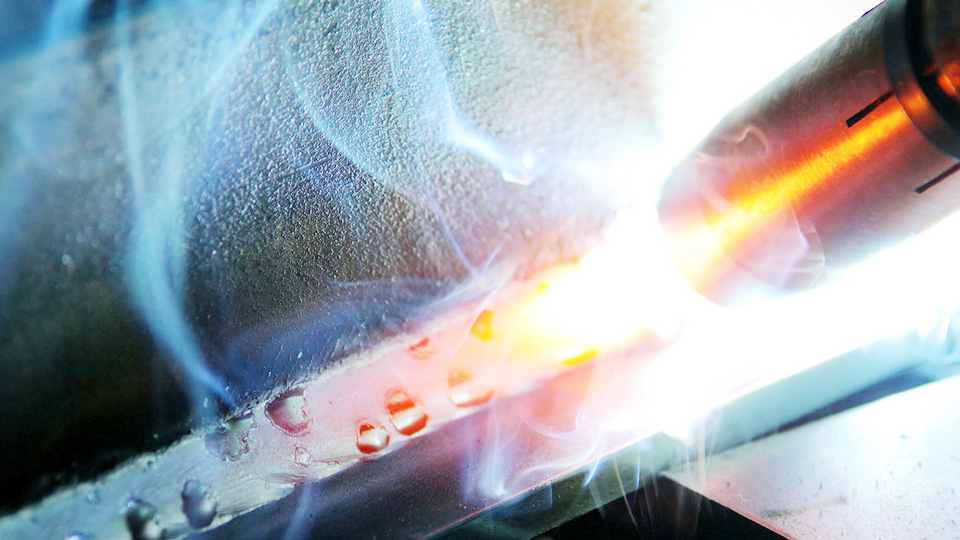

Image by directindustry

Hot Pressure Welding

Hot pressure welding is a solid-state welding process that involves applying heat and pressure to weld materials together. Unlike fusion welding, which melts the base materials, hot pressure welding relies on the application of heat to achieve plastic deformation, thereby joining the materials. This method is often used to weld metals that have high melting points or are difficult to weld using conventional techniques.

What is Hot Pressure Welding?

Hot pressure welding combines mechanical pressure and heat to create a weld. The process involves heating the materials to a temperature below their melting point, applying pressure, and holding them together until a solid bond forms. This method is ideal for materials that are sensitive to heat and require precise control to prevent degradation.

How Does Hot Pressure Welding Work?

The hot pressure welding process typically involves the following steps:

Preparation: The surfaces of the materials to be welded are cleaned and prepared to ensure a good bond.

Heating: The materials are heated to a specific temperature, usually below their melting point, to make them pliable.

Application of Pressure: Once the materials reach the desired temperature, pressure is applied to fuse them together.

Cooling: After the pressure is applied, the materials are allowed to cool under pressure to form a strong, solid weld.

Types of Hot Pressure Welding Equipment

Hot pressure welding equipment varies depending on the specific requirements of the welding process and the materials being welded. The main types of equipment used in hot pressure welding include:

Friction Welding Equipment

Friction welding involves the generation of heat through friction between the rotating workpieces. The heat generated softens the material, and pressure is applied to forge the pieces together. This equipment is typically used for welding cylindrical or cylindrical-shaped components.

Features:

- High Rotation Speed: Generates the necessary frictional heat.

- Pressure Control: Ensures the correct amount of force is applied.

- Cooling System: Cools the weld area after the process is complete.

Upset Welding Equipment

Upset welding, also known as forge welding, involves heating the materials and then applying pressure to upset or deform them at the weld interface. This method is commonly used for welding bolts, rods, and similar components.

Features:

- Heat Source: Often uses an electric or gas furnace.

- Pressure Mechanism: Typically includes hydraulic or pneumatic systems.

- Temperature Control: Ensures consistent heating of materials.

Diffusion Welding Equipment

Diffusion welding is a process that involves heating the materials to a temperature where diffusion occurs at the interface. Pressure is applied to achieve the weld. This type of equipment is used for welding complex geometries and high-strength materials.

Features:

- Controlled Atmosphere: Prevents contamination of the weld.

- High-Temperature Capability: Allows for welding of high-strength materials.

- Pressure System: Maintains consistent pressure during the welding process.

Explosion Welding Equipment

Explosion welding uses a controlled explosive charge to create high-pressure conditions that weld two materials together. This method is used for materials that are difficult to weld using conventional techniques.

Features:

- Explosive Charge: Creates the high-pressure conditions needed for welding.

- Protective Enclosures: Ensures safety during the explosive process.

- Precise Control: Manages the explosion to achieve the desired weld quality.

Applications of Hot Pressure Welding

Hot pressure welding is used in various industries due to its ability to create strong, durable welds. Some common applications include:

Automotive Industry

In the automotive industry, hot pressure welding is used to join components like engine parts, exhaust systems, and suspension components. The process ensures strong joints that can withstand high stress and temperatures.

Aerospace Industry

Aerospace components often require welding of high-strength materials, which makes hot pressure welding ideal. This method is used for joining parts of aircraft and spacecraft, where precision and strength are crucial.

Construction Industry

Hot pressure welding is used in the construction industry for joining structural components, such as beams and columns. This ensures the structural integrity of buildings and bridges.

Electronics Industry

In the electronics industry, hot pressure welding is used to join delicate components, such as sensors and connectors. The process allows for precise welding without damaging the components.

Advantages of Hot Pressure Welding

Hot pressure welding offers several advantages over other welding methods:

High-Quality Joints

The process produces high-quality welds with minimal defects, making it suitable for critical applications where strength and reliability are paramount.

Minimal Heat-Affected Zone

Since the materials are heated below their melting point, the heat-affected zone is minimized, reducing the risk of material degradation and maintaining the integrity of the weld.

Versatility

Hot pressure welding can be used to weld a wide range of materials, including metals that are difficult to weld using conventional methods.

Reduced Distortion

The controlled heating and pressure application help minimize distortion, ensuring that the welded components maintain their original dimensions and shapes.

Considerations for Selecting Hot Pressure Welding Equipment

When selecting hot pressure welding equipment, several factors should be considered:

Material Type

Different materials require different welding techniques and equipment. Ensure that the equipment you choose is suitable for the materials you plan to weld.

Weld Quality

Consider the quality of welds produced by the equipment. Look for features that enhance weld quality, such as precise temperature control and pressure mechanisms.

Equipment Size and Capacity

Select equipment that matches the size and capacity requirements of your welding projects. Larger projects may require more robust equipment with higher capacity.

Cost and Maintenance

Evaluate the cost of the equipment and the associated maintenance requirements. Higher-quality equipment may have a higher initial cost but could result in lower long-term maintenance expenses.

Safety Features

Ensure that the equipment has adequate safety features to protect operators and prevent accidents. This includes protective enclosures, safety alarms, and emergency shut-off mechanisms.

Conclusion

Hot pressure welding is a valuable process in various industries, offering high-quality welds with minimal material degradation. Understanding the different types of hot pressure welding equipment, their applications, advantages, and selection criteria can help you choose the right equipment for your needs.

If you’re working in automotive, aerospace, construction, or electronics, hot pressure welding provides a reliable and effective solution for creating strong, durable welds.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.