The first time I tried to TIG weld cast iron to mild steel, I treated it like any other weld—clean the joint, strike an arc, and lay a bead. Within minutes of cooling, the whole thing cracked like glass. That’s when it hit me: cast iron and mild steel expand and contract at completely different rates, and if you don’t account for that, your weld doesn’t stand a chance.

I’ve figured out how to make the two metals work together—using nickel filler rods, careful preheating, and slow, controlled cooling to keep stress out of the weld. It’s not about rushing; it’s about managing heat and respecting the materials. In this guide, I’ll walk you through the exact method I use to TIG weld cast iron to mild steel without ending up with a brittle, cracked mess.

Image by reddit

Can You TIG Weld Cast Iron to Mild Steel?

Absolutely, you can TIG weld cast iron to mild steel, but it’s not always the first choice. TIG, or Tungsten Inert Gas welding, uses a non-consumable tungsten electrode and inert gas like argon to shield the weld. It gives you precise control over heat input, which is crucial when dealing with cast iron’s sensitivity to thermal stress.

Why consider it? For repairs where you need a clean, high-quality joint without spatter, like on automotive parts or machinery brackets. I’ve used TIG on thin cast iron brackets attached to mild steel frames, and it worked like a charm when I controlled the heat. But if the part is load-bearing or under high stress, think twice—cast iron’s brittleness can lead to cracks if not handled right.

In practice, TIG is better for thinner sections or non-critical applications. For thicker pieces, other methods like stick welding might be more forgiving. Always check if your project aligns with US welding codes like AWS D14.1 for machinery repairs to ensure compliance.

Why Choose TIG for Welding Cast Iron to Steel?

TIG stands out for its precision and low heat input compared to MIG or stick. When welding dissimilar metals like cast iron (high carbon, brittle) to mild steel (low carbon, ductile), you need to minimize distortion and cracking. TIG lets you add filler slowly, building the weld puddle with control.

In real-world scenarios, this matters for safety— a cracked weld on a pressure vessel or structural support could be disastrous. It also boosts weld integrity by reducing porosity and inclusions. Cost-wise, while TIG machines like a Miller Dynasty or Lincoln Square Wave cost more upfront, they save on rework by getting it right the first time.

I remember a job where I TIGged a cast iron flange to a mild steel pipe for a custom exhaust system. The low heat prevented warping, and the joint held up under heat cycles. For students or hobbyists, TIG teaches finesse, helping you understand material compatibility better.

Materials Needed for TIG Welding Cast Iron to Mild Steel

Gather your gear before striking an arc. You’ll need a TIG welder capable of DC output for steel and cast iron—AC is for aluminum, but stick to DC here. A foot pedal for amperage control is a must for heat management.

For filler, high-nickel rods are key. More on that later, but stock up on ERNi-1 or similar. Argon gas at 15-20 CFH flow rate shields the weld. Don’t forget PPE: welding helmet with shade 10-12, leather gloves, and a respirator for fumes.

Other tools: Angle grinder for prep, wire brush for cleaning, and a hammer for peening. For preheat, a propane torch or oven works. I’ve used a basic setup in my garage—a Harbor Freight TIG machine did the trick for small jobs, proving you don’t need top-dollar gear to start.

Best Filler Rods for TIG Welding Cast Iron to Mild Steel

Choosing the right filler is half the battle. High-nickel fillers like Ni99 or ERNi-CI are top picks because they provide ductility, bridging the gap between brittle cast iron and flexible mild steel. They absorb stresses and prevent cracking.

I’ve had success with Ni55 rods on repairs—they’re machinable and resist carbon migration from the cast iron. Stainless fillers like ER309 or ER312 can work in a pinch for their high alloy content, but they’re not ideal; they can lead to brittle zones if not preheated properly.

For TIG brazing alternative, silicon bronze like ERCuSi-A flows at lower temps, reducing heat input. Avoid standard steel fillers like ER70S-6—they’ll crack due to carbon dilution.

Here’s a quick comparison:

| Filler Type | Pros | Cons | Best For |

|---|---|---|---|

| High-Nickel (Ni99) | Ductile, crack-resistant, machinable | Expensive, requires slow cooling | Critical repairs |

| Stainless (ER309) | Readily available, good for dissimilar metals | Can form brittle zones, less ductile | Non-structural joints |

| Silicon Bronze | Low heat, easy flow | Weaker than welded joint | Brazing thin sections |

Pick based on your project— for a hobbyist fixing a bracket, bronze might suffice; pros on industrial work, go nickel.

Preparation Tips for TIG Welding Cast Iron and Mild Steel

Prep work sets you up for success. Start by cleaning both metals thoroughly—cast iron often has graphite and oils that cause porosity. Use a wire brush or grinder to remove rust, paint, and scale. For cast iron, avoid carbide tools; they can embed particles.

Bevel the edges for better penetration, especially on thicker pieces. A 60-degree V-groove works well. Match the joint type—butt for flat plates, lap for brackets.

Personal tip: I once skipped thorough cleaning on a cast iron to steel weld, and the porosity ruined the joint. Lesson learned—degrease with acetone and brush until shiny.

For material compatibility, remember cast iron expands more than mild steel, so plan for that in your setup to avoid distortion.

Preheat Requirements for Cast Iron Before TIG Welding

Preheat is non-negotiable to prevent cracking. Heat the cast iron to 500-700°F evenly—use a temp stick or infrared thermometer. For small parts, a propane torch suffices; larger ones, an oven.

Why? Cast iron cools fast, creating stresses. Preheat equalizes expansion. I’ve preheated a cast iron manifold to 600°F before TIGging it to mild steel tubing, and it held without a hitch.

Common mistake: Uneven heating—spot heat leads to hot spots and cracks. Fix: Heat the whole piece slowly. For DIYers, wrap in insulation to hold heat.

Step-by-Step Guide to TIG Welding Cast Iron to Mild Steel

Let’s get hands-on. This guide assumes you’re set up with your TIG machine on DCEN (electrode negative) for penetration.

Step 1: Prep the materials—clean, bevel, and clamp securely. Ensure good fit-up to minimize gaps.

Step 2: Preheat the cast iron to 500-700°F. Keep the mild steel at room temp or lightly warm.

Step 3: Set your machine—start at 80-120 amps for 1/8-inch material, adjust with foot pedal. Gas flow 15-20 CFH argon.

Step 4: Tack weld first—short bursts to hold position without full heat.

Step 5: Weld in short runs, 1-2 inches at a time. Dip the nickel filler into the puddle, keeping a tight arc.

Step 6: Peen each bead while hot—use a hammer to relieve stress. This stretches the weld as it cools.

Step 7: Allow cooling between runs—touch test: if you can touch it, proceed.

Step 8: Complete the weld, building layers if needed for strength.

I followed this on a repair for a friend’s vintage tractor part—short runs and peening saved it from cracking.

Machine Settings for TIG Welding Dissimilar Metals

Settings vary by thickness, but here’s a baseline for 1/4-inch cast iron to mild steel:

- Amperage: 100-150 amps, pedal control for ramping.

- Voltage: 10-15V.

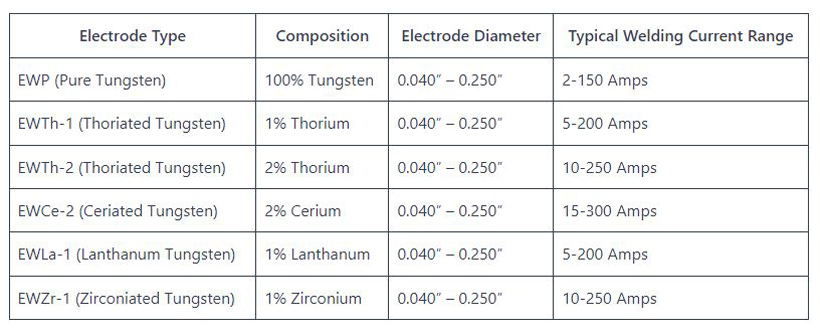

- Tungsten: 3/32-inch thoriated or lanthanated, sharpened to a point.

- Filler diameter: 1/16-inch for fine control.

- Polarity: DCEN.

Tip: Start low and increase—overheating cast iron is a killer. On my Miller machine, I use pulse mode at 50-100 PPS to control heat input.

Common fix: If the puddle’s too hot, back off the pedal and increase travel speed.

Techniques to Avoid Cracking in Cast Iron Welds

Cracking is the enemy. Use short beads to limit heat zones. Peen immediately after welding—hit the bead 20-30 times with a chipping hammer to expand it.

Maintain interpass temp around 500°F. I’ve seen cracks form from long continuous welds; breaking it up fixed that.

For thin sections, TIG brazing with bronze reduces risk—no melting the base metal, just flowing filler.

Anecdote: On a job site, a trainee welded too long without peening—crack city. We ground it out, preheated more, and short-beaded it successfully.

Post-Weld Cooling and Treatment for Weld Integrity

Slow cooling is as important as preheat. Bury the piece in dry sand or vermiculite, or use a ceramic blanket to insulate. Drop temp gradually, like 100°F per hour.

Why? Rapid cooling hardens the heat-affected zone. I’ve wrapped parts in welding blankets overnight, and it prevented stress cracks.

Inspect after cooling—use dye penetrant for hidden flaws. If machining, use nickel fillers for easier work.

Mistake: Quenching in water— instant cracks. Fix: Always air or insulated cool.

Common Mistakes and Fixes in TIG Welding Cast Iron to Steel

Mistake 1: No preheat—leads to immediate cracks. Fix: Always preheat to at least 500°F.

Mistake 2: Wrong filler—steel rods cause brittleness. Fix: Switch to nickel-based.

Mistake 3: Fast cooling—stresses build up. Fix: Insulate for slow cool.

Mistake 4: Poor cleaning—porosity galore. Fix: Brush and degrease thoroughly.

I’ve made these early on, like using ER70S on a test piece—snapped right away. Learning curve, but now I double-check everything.

Pros and Cons of TIG Welding vs Other Methods for Cast Iron to Steel

TIG isn’t always best—compare it:

| Method | Pros | Cons |

|---|---|---|

| TIG | Precise, low spatter, good control | Slow, requires skill, heat sensitive |

| Stick (SMAW) | Forgiving, good for thick sections | Spatter, less clean |

| MIG | Faster, easier for beginners | Higher heat, potential distortion |

| Brazing | Low heat, no cracking | Weaker joint, not for high stress |

For hobbyists, TIG’s control is great; pros might stick weld for speed on site.

Real-World Applications and Examples

In the US, this comes up in auto repairs—like welding cast iron exhaust manifolds to mild steel pipes. Or fabrication: attaching cast iron feet to mild steel tables.

On a job, I TIGged cast iron brackets to mild steel frames for heavy machinery—preheat and nickel filler ensured it met safety specs.

For students, practice on scrap: join a cast iron skillet piece to steel plate. Hobbyists, think custom grills or art pieces.

Safety Considerations When TIG Welding Cast Iron

Safety first—cast iron fumes can be nasty, so use a fume extractor or respirator. Preheat risks burns, so wear full leather.

TIG’s UV light demands a good helmet. Ground properly to avoid shocks. I’ve seen guys skip ventilation and regret it—don’t be them.

Follow OSHA guidelines for welding in confined spaces.

Alternatives to TIG for Joining Cast Iron and Mild Steel

If TIG’s not clicking, try brazing with oxy-acetylene and bronze rod—lower heat, less crack risk. Mechanical fastening with bolts works for non-welded joints.

Stick with nickel electrodes like ENi-CI is simpler for some. I’ve switched to brazing on delicate repairs, saving time and frustration.

Conclusion

Wrapping this up, you’ve got the tools to tackle how to TIG weld cast iron to mild steel with confidence. Key takeaways: Preheat to 500-700°F, use high-nickel fillers, weld in short beads with peening, and cool slowly to avoid cracks. You’re now better prepared because you understand the why behind each step—material differences, heat control, and stress relief. This knowledge lets you choose the right process, whether TIG, brazing, or another, for safe, strong welds.

FAQ

Can cast iron be TIG welded to steel without cracking?

Yes, but preheat to 500-700°F, use nickel filler, peen the beads, and cool slowly in sand or insulation to minimize cracking risks.

What filler rod is best for welding cast iron to mild steel?

High-nickel rods like Ni99 or ERNi-1 are best for ductility and crack resistance; stainless like ER309 works but isn’t ideal.

Do I need to preheat cast iron for TIG welding?

Absolutely—preheat prevents thermal shock and cracking; aim for even heating to 500-700°F with a torch or oven.

Is TIG better than MIG for cast iron to steel welds?

TIG offers better heat control for precision, but MIG is faster; choose TIG for clean, critical joints and MIG for production.

How do I cool a cast iron to steel weld properly?

Insulate with sand, vermiculite, or a ceramic blanket for gradual cooling—avoid rapid cooling to prevent stress cracks.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.