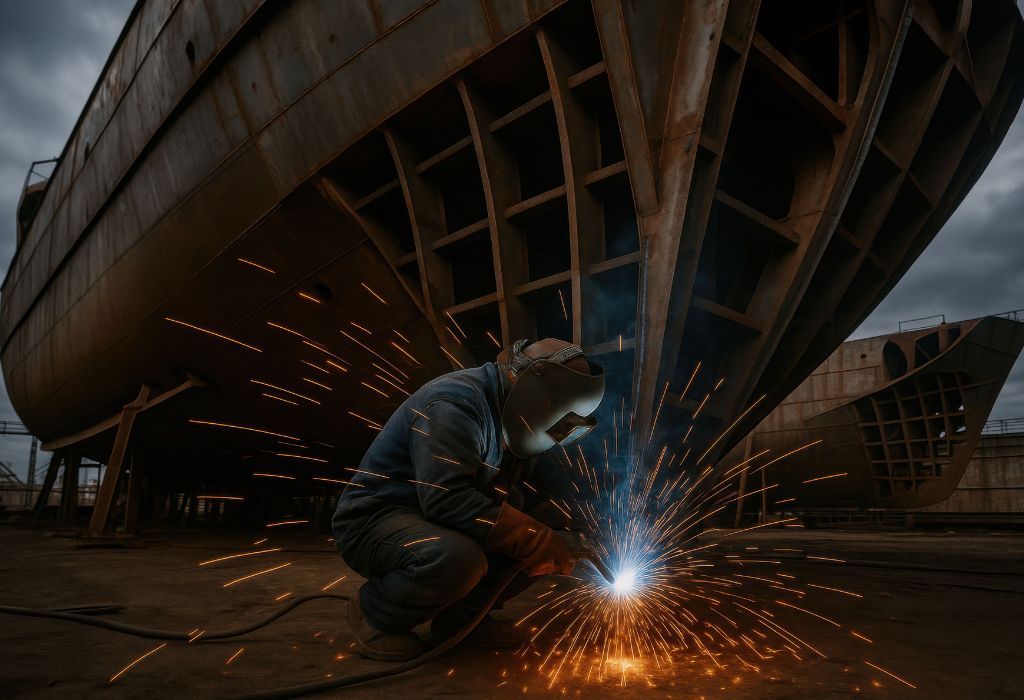

Dawn breaks over a bustling shipyard as steel plates swing from cranes and sparks shower across the dock.

In this world of towering hulls and constant motion, a vital question often arises: what does a shipyard welder do behind the mask and flame?

The role is more than melting metal together. Shipyard welders work in environments where precision and safety determine the seaworthiness of entire vessels.

Their duties stretch from fabricating new hull modules to repairing corroded sections on massive cargo ships.

Every bead laid down carries the weight of global trade and naval readiness.

Shipyards are complex workplaces, combining heavy construction with strict safety measures

. According to OSHA, shipyard employees face higher accident risks than most construction sectors, with hazards ranging from hot work and confined spaces to toxic fume exposure (OSHA).

Yet with training, protective equipment, and adherence to codes, welders transform steel into reliable structures that last decades.

The profession is also in steady demand. The U.S. Bureau of Labor Statistics reports more than 45,000 welding openings each year through 2034, fueled by retirements and shipbuilding projects (BLS).

For new workers entering the trade, this means both opportunity and responsibility.

This guide explores the full scope of shipyard welding—core duties, tools, processes, safety practices, and career paths.

By understanding these responsibilities, aspiring welders and curious readers alike will gain a clear picture of the craft that keeps fleets afloat and shipyards thriving.

Quick Answer — What Does a Shipyard Welder Do?

A shipyard welder fabricates, repairs, and maintains steel and alloy structures on ships. They read blueprints, prepare joints, set up equipment, and lay down welds that meet strict codes. Their work ensures the structural integrity of hulls, decks, bulkheads, and piping systems.

Welders in shipyards may spend their day in workshops, dry docks, or confined spaces inside vessels. They often switch between processes like FCAW, SMAW, GMAW, and GTAW, depending on the job’s requirements.

Do shipyard welders only weld all day?

No. They also cut, bevel, grind, fit parts, and inspect welds before and after completion.

Do they work on new builds or repairs?

Both. Shipyard welders are assigned to construction of new vessels and to maintenance or retrofitting of older ships.

Which welding processes are most common in shipyards?

FCAW and GMAW dominate for speed and efficiency, while SMAW and GTAW are used in repairs and specialized work.

Is blueprint reading part of the job?

Yes. Welders must interpret drawings, weld maps, and procedure specifications before striking an arc.

Do they work indoors or outdoors?

Both. Tasks range from shop fabrication to welding in open-air docks and tight spaces below deck.

Core Duties (Day-to-Day Tasks)

Shipyard welders move through a predictable cycle: preparation, welding, and inspection. Each stage requires discipline and technical knowledge.

Prep & Fit-Up

Preparation starts long before the arc is lit. Welders bevel edges, clean surfaces, and align heavy plates with clamps, wedges, and strongbacks.

Do welders bevel plates themselves?

Yes. They often use grinders or torches to create bevels per welding procedure.

Why is cleanliness so critical?

Contaminants like paint or rust weaken welds and cause defects.

Do welders set preheat conditions?

They follow specifications, using torches or heaters to prevent cracking.

How is alignment checked?

Fit-up is verified with gauges and adjusted using clamps or wedges.

Do supervisors approve before welding starts?

Yes. Inspections confirm joints meet code before arcs are struck.

Welding & Gouging

After prep, welders strike arcs with processes suited to the job. FCAW dominates for heavy plate, while SMAW is used in tight repairs.

Why is FCAW popular in shipyards?

It offers high deposition rates and works well on thick steel.

Is stick welding still common?

Yes. It’s versatile and useful outdoors or in confined spaces.

What about TIG welding?

TIG is essential for thin metals, stainless steel, and piping systems.

Do welders gouge out old welds?

Yes. Air carbon arc gouging removes defects before repairs.

Can welders switch processes in one shift?

Absolutely. Shipyard jobs often demand multiple techniques in a single day.

Inspection & Rework

No weld leaves without checks. Welders clean, inspect, and assist NDT technicians with testing.

Do welders perform NDT themselves?

Usually not. Certified technicians handle UT, MT, or RT testing.

What happens if a weld fails inspection?

It’s gouged out and rewelded until it meets quality standards.

Are all defects serious?

Some, like porosity, can be minor. Others, like lack of fusion, require major repairs.

Do welders document their work?

Yes. They record heat numbers, filler batches, and inspection results.

Is rework common?

Yes. Even skilled welders face repairs due to complex shipyard conditions.

Work Environment & Conditions

Shipyard welding blends heavy industry with marine challenges. Tasks are performed indoors, outdoors, and often in confined areas.

Locations & Shifts

Welders rotate between block assembly shops, dry docks, and vessel interiors. Shifts can last 8 to 12 hours with frequent overtime.

Do welders work in confined spaces?

Yes. Tanks and bilges require permits, ventilation, and safety attendants.

Does weather impact welding?

Yes. Wind, rain, and tides can disrupt shielding gas and access.

Are night shifts common?

Yes. Deadlines drive around-the-clock work.

Is overtime expected?

Often. Ship launches and deadlines demand extra hours.

Can welders be reassigned daily?

Yes. Job sites and tasks change with project needs.

Tools & Equipment

Shipyard welders rely on heavy-duty machines and portable tools. Wire feeders, torches, grinders, and positioners are everyday essentials.

Do welders bring their own tools?

Yes. Hand tools are personal, but yards provide power equipment.

Are lifts and platforms used?

Yes. Welders often work from cherry pickers or scaffolding.

Is fume extraction required?

Yes. Ventilation reduces exposure to hazardous gases.

Are special clamps used?

Yes. Strongbacks, wedges, and dogs hold steel plates in alignment.

Is PPE considered part of equipment?

Yes. Helmets, gloves, and respirators are non-negotiable gear.

Welding Processes in Shipyards

Processes are chosen for speed, precision, and environment.

Flux-Cored Arc Welding (FCAW)

Why use FCAW?

It’s fast, efficient, and handles thick steel plate.

Self-shielded or gas-shielded?

Both. Gas-shielded dominates shops, while self-shielded works outdoors.

Does FCAW create more fumes?

Yes, which is why ventilation is critical.

Can FCAW be used overhead?

Yes, with the right consumables.

Is it cost-effective?

Yes. Its productivity outweighs higher filler costs.

Gas Metal Arc Welding (GMAW/MIG)

Where is MIG used in shipyards?

Outfitting, thin plate, and controlled environments.

Is it faster than stick welding?

Yes, but requires shielding gas protection.

Does MIG handle thick steel?

Not as effectively as FCAW.

What’s the main risk?

Porosity from poor prep or gas coverage.

Is MIG beginner-friendly?

Yes, but precision is still needed.

Shielded Metal Arc Welding (SMAW/Stick)

Why is SMAW still relevant?

It works in repairs and difficult positions.

Which electrodes are used?

E7018 is standard for shipyard structural welding.

Is SMAW portable?

Yes. It’s ideal for remote and outdoor jobs.

Does it require gas?

No. The electrode flux provides shielding.

Is it slower than other processes?

Yes, but extremely versatile.

Gas Tungsten Arc Welding (GTAW/TIG)

When is TIG used?

For piping, stainless steel, and cosmetic welds.

Is it slower than other methods?

Yes, but offers unmatched precision.

Does TIG require high skill?

Yes. It demands steady hands and expertise.

Is TIG common in repairs?

Yes, especially for critical components.

Does TIG need special shielding gas?

Yes. Argon or mixed gases are used for protection.

Safety: Hazards, Controls, and PPE

Welding in shipyards comes with serious risks. OSHA highlights fire, fumes, and confined-space dangers as top hazards.

What are the biggest hazards?

Fires, toxic fumes, electrical shock, and falls.

How are risks controlled?

Permits, ventilation, PPE, and strict procedures.

Is confined-space work dangerous?

Yes. Atmosphere testing and attendants are mandatory.

Do welders face hearing loss risks?

Yes. Noise levels demand hearing protection.

Are respiratory hazards common?

Yes. Fumes from fluxes and metals require respirators.

Skills & Qualifications

Shipyard welders need both technical ability and discipline.

Do they need certifications?

Yes. AWS or employer-specific tickets are required.

Is blueprint reading essential?

Absolutely. Welders must interpret symbols and maps.

What soft skills help?

Teamwork, focus, and adaptability.

Do shipyards train new welders?

Yes. Many offer apprenticeships or on-site programs.

Are specialized tests common?

Yes. Welders must pass procedure qualification tests.

Career Paths, Pay & Outlook

The U.S. Bureau of Labor Statistics shows welders earn a median of $51,000 annually with growth tied to industry demand (BLS).

Do shipyard welders earn more than shop welders?

Often. Marine projects pay higher for difficulty and hazards.

Can welders move into inspection roles?

Yes. Many transition into NDT or QC.

Is overtime common in paychecks?

Yes. Launch schedules create lucrative overtime opportunities.

Do unions exist in shipyards?

Yes. They influence pay and benefits in many regions.

Are welding jobs secure?

Yes. Retirements and shipbuilding backlogs sustain demand.

A Day on the Job

A shipyard welder might begin in a panel shop, spend midday in a dry dock, and finish in a confined space inside a hull. Each setting requires flexibility.

Is every day the same?

No. Tasks vary by project phase.

Do welders follow strict schedules?

Yes. Deadlines shape daily work.

Are inspections daily?

Yes. QC checks happen continuously.

Do welders always work in teams?

Usually. Safety and efficiency require coordination.

Is paperwork part of the job?

Yes. Documentation tracks compliance and materials.

Conclusion

So, what does a shipyard welder do? They cut, fit, weld, and repair the massive steel structures that carry the world’s cargo and navies across oceans. From FCAW on hull modules to TIG on stainless piping, every task demands precision, safety, and resilience.

The role is challenging, but it offers steady work, solid pay, and the pride of contributing to global industries. For those willing to master the craft, the shipyard is a classroom and career path rolled into one.

Final advice: Learn multiple welding processes, respect safety rules, and document your skills. That approach turns shipyard work into a long and rewarding career.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.