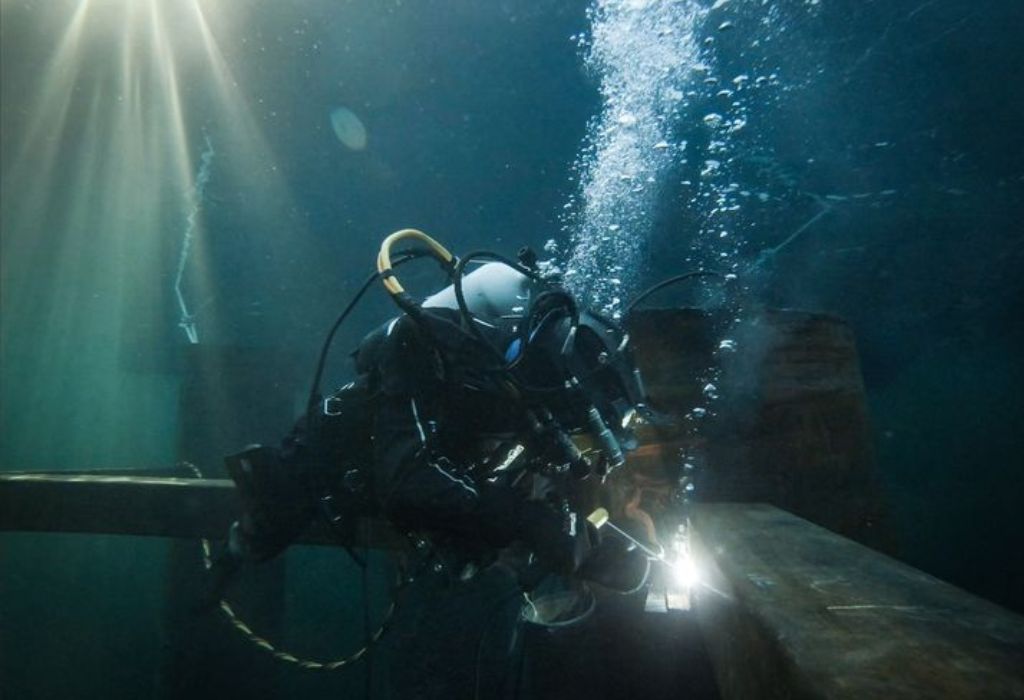

Underwater welding, also called hyperbaric welding, is the process of joining metal components while submerged in water — often at extreme depths where pressure and visibility challenge even the most skilled divers. It is one of the rare trades that blend engineering, metallurgy, and professional diving into one specialized discipline.

In essence, underwater welding works by creating a controlled arc between the electrode and the metal surface, even under high water pressure.

The heat generated melts the metal surfaces, forming a strong bond that restores or reinforces structures like pipelines, rigs, or ship hulls.

There are two primary types of underwater welding — wet welding and dry welding .

Wet welding happens directly in the water, where the diver uses a specially designed waterproof electrode, while dry welding occurs inside a sealed, pressurized chamber filled with a breathable gas mixture, such as helium and oxygen.

Wet welding is faster and more cost-effective but produces lower-quality joints due to rapid cooling and hydrogen embrittlement.

In contrast, dry or hyperbaric welding delivers cleaner, stronger welds but demands extensive setup and higher operational costs.

This distinction defines how professionals plan and execute how to weld underwater, depending on factors like depth, structure type, and environmental conditions.

What Is Underwater Welding (Hyperbaric & Wet)?

Underwater welding, also called hyperbaric welding, is the process of joining metal components while submerged in water — often at extreme depths where pressure and visibility challenge even the most skilled divers. It is one of the few trades that combine engineering, metallurgy, and commercial diving.

In essence, underwater welding works by creating an electric arc between the electrode and the metal surface. The intense heat melts the metal edges, forming a solid bond when cooled.

There are two main types of underwater welding: wet welding and dry (hyperbaric) welding. Wet welding occurs directly in the water, while dry welding takes place in a sealed chamber pressurized with gas.

Wet welding is faster and cheaper but more prone to defects like porosity and cracking. Dry welding delivers stronger joints but requires complex setup and high operational costs.

This distinction is fundamental to mastering how to weld underwater, as the choice between wet and dry welding depends on project needs, depth, and safety conditions.

What does “hyperbaric” mean in underwater welding?

It refers to welding done inside a pressurized gas chamber to create a dry environment underwater.

What’s the difference between wet and dry welding?

Wet welding happens directly in water using waterproof electrodes, while dry welding takes place in a sealed chamber.

Why is underwater welding necessary?

It allows fast, cost-effective repair of ships, pipelines, and offshore structures without removing them from the water.

Can standard welding be done underwater?

No. Underwater welding requires insulated power systems and specialized electrodes to prevent electric shock.

Which method produces stronger welds?

Dry welding creates stronger, cleaner joints due to its controlled atmosphere.

Techniques and Processes in How to Weld Underwater

The process of how to weld underwater begins with understanding two core methods: wet and dry welding. Each technique demands specialized preparation, precise coordination, and advanced knowledge of underwater environments.

In wet welding, divers use waterproof electrodes powered by a DC current, forming an arc through a gas bubble around the weld tip. The gas bubble insulates the arc from water, though cooling happens fast, affecting weld quality.

Dry or hyperbaric welding, on the other hand, involves enclosing the work area within a chamber filled with helium and oxygen. The welder operates in this dry habitat using conventional techniques like SMAW or TIG, achieving near-surface quality results.

Several welding methods are used underwater — shielded metal arc welding (SMAW), flux-cored arc welding (FCAW), and friction stud welding are the most common. The choice depends on material type, accessibility, and environmental factors.

Understanding the arc behavior, electrode type, and pressure control is essential for consistent results when learning how to weld underwater.

How does the arc stay stable underwater?

A gas bubble created by the electrode shields the arc from water, maintaining stability.

What welding methods are used underwater?

SMAW, FCAW, and friction stud welding are common for both wet and dry environments.

Can TIG welding be used underwater?

Yes, but it’s limited to dry chamber setups where inert gas can be properly controlled.

How is pressure managed in dry welding?

Chambers are pressurized to match surrounding water pressure, preventing collapse.

Why is cooling a problem in wet welding?

Rapid cooling from water exposure can lead to brittle welds and cracking.

Equipment and Tools for Underwater Welding

Mastering how to weld underwater requires more than skill — it depends on precision-engineered equipment built for extreme pressure and moisture resistance.

Every diver-welder wears a commercial diving suit equipped with a helmet, breathing apparatus, and communication system. These ensure safety and constant contact with surface crews.

For wet welding, specialized waterproof electrodes, power cables, and insulated stingers prevent current leakage. The power source must supply steady DC current with negative polarity to minimize hydrogen generation.

Dry or hyperbaric welding uses chambers or “habitats” — sealed capsules fitted with gas supplies, pressure controls, and lighting systems. Inside, welders use standard tools similar to those used on land, including TIG and MIG equipment.

Additional tools include non-destructive testing devices, grounding clamps, and emergency cut-off switches. Each is vital for safety and precision during underwater operations.

What certification is required for underwater welders?

Divers must hold a commercial diving license and specialized underwater welding certification.

What are waterproof electrodes made of?

They’re coated with special compounds that prevent moisture intrusion and stabilize the arc.

How do welding chambers work underwater?

They trap dry air or inert gas around the weld zone, allowing traditional welding techniques.

What type of power is used underwater?

Direct current (DC) with negative polarity is preferred to reduce electric shock risk.

What safety gear is mandatory?

Insulated gloves, dry suits, full-face helmets, and backup air systems are essential.

Challenges, Risks, and Quality Issues in How to Weld Underwater

While lucrative, underwater welding is among the most dangerous jobs in industrial trades.

The combination of electricity, water, and pressure makes safety the top priority in learning how to weld underwater.

The most critical hazard is electric shock, which can occur from faulty insulation or damaged cables. Hydrogen and oxygen gas bubbles formed during welding can cause underwater explosions if not vented properly.

Other challenges include hydrogen embrittlement, rapid cooling, and material cracking. Water pressure and limited visibility make precision welding difficult, leading to quality inconsistencies.

Depth is another factor — for every 10 m descended, pressure increases significantly, making physical exertion and decompression management harder. Poor welds can compromise entire marine structures, making testing essential.

What makes underwater welding dangerous?

The mix of electricity and water poses shock and explosion risks.

What is hydrogen embrittlement?

Hydrogen absorbed into the metal weakens its structure, causing cracks.

How is weld quality tested underwater?

Ultrasonic and radiographic inspections ensure structural integrity.

Does depth affect weld performance?

Yes. Increased pressure alters gas behavior and cooling rates, affecting fusion quality.

How do divers handle visibility issues?

Powerful lights and camera systems are used, but training and experience remain crucial.

Best Practices and Safety Protocols for How to Weld Underwater

Safety is the cornerstone of professional underwater welding.

Before any operation, divers and engineers must perform a detailed site survey, review structure integrity, and confirm environmental conditions.

Proper grounding and insulation are essential to avoid electric current leakage. Cables should be routed carefully, and electrodes changed only when circuits are de-energized.

Decompression procedures must be strictly followed to prevent the “bends.” Divers often use saturation systems allowing longer work times and controlled ascent schedules.

Every project requires communication protocols, surface supervision, and emergency recovery plans.

Following these standards ensures that learning how to weld underwater becomes a sustainable, safe profession.

How is safety ensured underwater?

Continuous monitoring, proper insulation, and emergency readiness are key.

Why is decompression so critical?

Improper decompression causes nitrogen bubbles in the bloodstream, leading to serious injury.

How do teams manage communication?

Full-duplex wired or wireless comms link divers with surface supervisors.

Are there fire risks underwater?

Yes. Gas mixtures can ignite in confined dry habitats if oxygen levels are uncontrolled.

What’s the safest way to change electrodes underwater?

Always disconnect power before replacing electrodes to prevent shock.

Applications and Use Cases of Underwater Welding

Underwater welding keeps vital marine infrastructure functioning around the globe.

It’s used for ship repair, offshore oil and gas platforms, pipelines, bridge foundations, and hydroelectric dams.

In shipping, it allows hull maintenance without dry-docking, saving days of downtime. Offshore rigs rely on underwater welders to repair risers, support frames, and wellheads.

Civil engineers use the same skills for underwater construction in ports, piers, and floodgates.

Emerging renewable energy projects like offshore wind farms increasingly depend on divers who understand how to weld underwater safely.

Where is underwater welding commonly used?

Marine, offshore oil, renewable energy, and civil engineering sectors.

Can welders work at great depths?

Yes, but specialized gas mixtures and decompression systems are needed beyond 300 m.

How does welding help offshore wind farms?

It maintains turbine foundations and support structures in harsh sea conditions.

Is underwater welding used in military operations?

Yes. Navies employ divers for ship repair and salvage missions.

How does it support infrastructure?

It enables real-time repair of critical underwater assets without relocation.

Emerging Trends and the Future of How to Weld Underwater

Technology is transforming how to weld underwater.

Remote-operated vehicles (ROVs) and robotic arms are increasingly used to handle repetitive or high-risk welds.

Automation and artificial intelligence assist in real-time monitoring, ensuring precision under variable conditions.

New electrode coatings are being developed to resist hydrogen absorption and improve arc stability.

Research into ultra-deep hyperbaric welding aims to push depth limits beyond 1,000 m, expanding applications in subsea energy and exploration.

Advanced sensors and smart helmets are also being introduced to monitor diver health and oxygen levels during missions.

Are robots replacing human underwater welders?

Not entirely. Robots handle repetitive work, but humans are still needed for complex repairs.

What new materials are used for electrodes?

High-nickel and flux-core variants reduce hydrogen absorption and improve strength.

Will AI change underwater welding?

Yes. AI assists in detecting flaws and adjusting current or gas flow automatically.

Can hyperbaric welding reach new depths?

Research suggests future chambers could operate safely beyond 1,000 m.

What’s next for underwater welders?

Hybrid teams of divers and robots will define the future of subsea engineering.

Conclusion

Learning how to weld underwater is mastering one of the most complex and rewarding crafts in the industrial world. It combines the discipline of diving, the precision of welding, and the resilience of working in extreme environments.

From wet welding in open water to dry hyperbaric operations, every method demands technical skill, physical endurance, and absolute safety awareness. As technology advances, new tools and robotic systems promise to make underwater welding safer and more efficient — but the courage of the diver-welder remains irreplaceable.For those ready to explore this remarkable profession, start by pursuing commercial diving certification and specialized training in underwater welding. With skill, discipline, and respect for the ocean’s power, you can master the art of how to weld underwater and join the elite community of underwater engineers shaping the world beneath the waves.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.