Ever tried to join two thick pieces of metal, only to have your weld look weak and disappointing? Working with half-inch steel can feel like a challenge, especially when you’re not sure what tool to use. It’s tough to know which MIG welder has enough power and the right features to get the job done right. You don’t want to spend your hard-earned money on a machine that can’t handle the thick stuff, or worse, end up with a weld that won’t hold.

Choosing the best MIG welder for half-inch steel is crucial for anyone building or repairing projects that need serious strength. This post cuts through the confusion. We’ll help you understand what makes a MIG welder powerful enough for thick metal and what features really matter. By the time you finish reading, you’ll know exactly what to look for, saving you time and frustration.

Let’s dive in and find the perfect MIG welder to tackle your half-inch steel projects with confidence. We’ll explore the key factors that make a MIG welder a champion for thick materials, ensuring your welds are strong and reliable.

Our Top 5 Mig Welder For 1/2 Steel Recommendations at a Glance

Top 5 Mig Welder For 1/2 Steel Detailed Reviews

1. ARCCAPTAIN Mig Welding Wire

Rating: 8.6/10

This ARCCAPTAIN Mig Welding Wire, 0.030 10Lb Mig Wire ER70S-6 10Lbs Gas Solid Carbon Steel Low Splatter Mig Welding Wire Compatible With Lincoln Miller Forney Harbor Welder 0.08 4.5KG is designed to help you create strong, clean welds. It’s made with high-quality materials and tested to meet industry standards. This wire works with many popular welding machines, making it a versatile choice for your projects.

What We Like:

- High-quality construction ensures consistent and strong welds.

- TÜV tested and approved, meaning it’s reliable and safe.

- Produces smooth weld beads with minimal cleanup needed.

- Offers optimal performance with less spatter for a cleaner look.

- Easy to use for both beginners and experienced welders.

- Works with many popular welding machines like Lincoln, Miller, and Forney.

What Could Be Improved:

- The 10lb spool might be too large for very small projects.

- Availability could be better in some local hardware stores.

This ARCCAPTAIN welding wire is a solid choice for anyone looking to improve their welding results. It offers great performance and ease of use for a variety of carbon steel projects.

2. Blue Demon ER70S6 X .030 X 11 LB MIG/GMAW Carbon Steel Welding Wire

Rating: 8.7/10

The Blue Demon ER70S6 X .030 X 11 LB MIG/GMAW Carbon Steel Welding Wire is a fantastic choice for many welding projects. This wire is .030 inches in diameter, making it great for detailed work. It’s designed for all positions, meaning you can weld up, down, and all around. You’ll love that it creates very little spatter, keeping your workspace cleaner. Plus, it’s made to give you welds that are free of holes and strong enough to pass X-ray tests.

What We Like:

- It works great for general shop jobs, even when the metal pieces don’t fit together perfectly.

- This wire is a lifesaver for fixing steel castings or worn-out forgings.

- Home DIYers will find this wire perfect for their projects.

- It’s engineered to produce welds that have no holes (porosity-free) and are strong enough for X-ray inspection, offering the highest tensile strength among plain carbon steel wires.

- You get all-position welding capability.

- Low spatter means less cleanup.

What Could Be Improved:

- This product requires a shielding gas like CO2 or a CO2 mix. You’ll need to have this on hand to use the wire.

This Blue Demon welding wire offers excellent performance for a wide range of applications. It’s a reliable option for both professional shops and home enthusiasts looking for quality welds.

3. AZZUNO Mig Solid Welding Wire

Rating: 9.1/10

If you’re looking for a reliable welding wire for your next project, the AZZUNO Mig Solid Welding Wire, ER70S-6 Mild Steel Gas Mig Wire .035″ 2-LB, 1-PACK is a great choice. This wire is designed for mild steel and works with gas MIG welding. It’s a popular option for both hobbyists and professionals.

What We Like:

- It’s easy for beginners to use, thanks to smooth feeding and low splatter.

- You get great welding results with a high deposition rate and deep penetration.

- The packaging is improved with a stronger spool and a moisture absorber to keep the wire in good condition.

- The wire has excellent arc stability, making it easy to get a good weld every time.

- AZZUNO offers helpful customer service if you have any questions or need support.

What Could Be Improved:

- The 2lb spool size might be a bit small for very large projects, requiring more frequent changes.

- While designed for ease of use, mastering any welding technique still takes practice.

This AZZUNO welding wire offers a user-friendly experience with impressive results. It’s a solid option for anyone wanting to achieve clean and strong welds.

4. ANDELI Plasma Cutter Welder Combo 160Amp Pulse MIG/HF TIG/HF Cut/Stick/Flux Core 6-in 1 Multi-Process Welder 110V/220V Dual Voltage Aluminium MIG Welding Machine Multi-Functional Welder MCT-416P

Rating: 8.7/10

The ANDELI Plasma Cutter Welder Combo MCT-416P is a powerful 6-in-1 welding and cutting machine. It handles various tasks like Pulse MIG, HF TIG, Plasma Cutting, MMA, SYN MIG, and MAN MIG. This makes it ideal for both pros and DIYers working on projects from building things to fixing equipment. It’s especially good for welding aluminum types like AlMg and Alsi.

What We Like:

- It’s a 6-in-1 machine, meaning it can do many different welding and cutting jobs.

- It works with both 110V and 220V power, giving you flexibility.

- The 5-inch LED screen makes it easy to see and choose your settings.

- It remembers your welding settings automatically, saving you time.

- It has safety features like auto shut-off and overheat protection.

- It comes with a two-year warranty and replacement parts.

- It includes all the necessary torches and accessories to get started.

What Could Be Improved:

- The maximum cutting current is 40A, which might not be enough for very thick materials.

- While it handles aluminum, some very specialized or thick aluminum projects might require a dedicated aluminum welder.

This ANDELI welder combo offers a lot of versatility for its price. It’s a solid choice for anyone needing a multi-functional machine for a variety of welding and cutting needs.

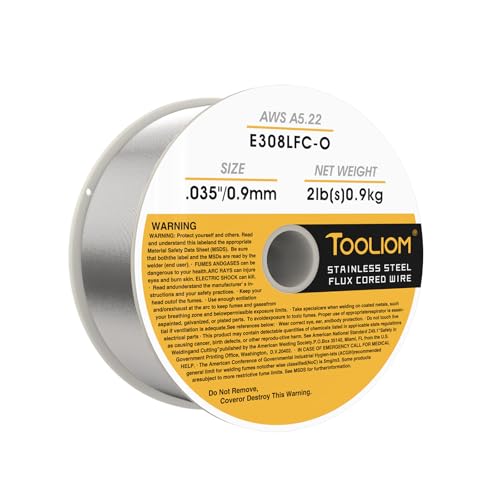

5. TOOLIOM Gasless Flux-Cored MIG Welding Wire

Rating: 9.2/10

The TOOLIOM Gasless Flux-Cored MIG Welding Wire is a game-changer for stainless steel projects. Its E308LFC-O formulation and .035″ diameter make it a versatile choice for many welding tasks. This 2 lb spool is designed for convenience and performance.

What We Like:

- The built-in flux core is a big help. It makes the welding arc steady and improves how well the wire works. This core also protects the weld.

- You get fewer messy splatters. This means your welds look cleaner and are of better quality.

- It’s great for welding materials that aren’t perfectly clean. Rusty, dirty, or even painted surfaces are no problem.

- This wire handles oil on the metal really well. It’s perfect for outdoor jobs, working at high places, or in tough spots.

- You can weld in any direction. Whether it’s flat, sideways, up, or overhead, this wire works.

- It’s good for both quick, single passes and more detailed, multi-pass welds.

- TOOLIOM stands behind its products. They want you to be happy and are there to help if you have questions.

What Could Be Improved:

- While it’s gasless, for very specific, high-end cosmetic stainless steel work, some professionals might prefer a gas-shielded option for ultimate control.

- The 2 lb spool is great for smaller projects, but for very large jobs, you might need to plan for multiple spools.

This TOOLIOM welding wire offers impressive performance and ease of use, especially for challenging materials. It’s a solid choice for DIYers and professionals looking for reliable gasless welding.

Choosing the Right MIG Welder for 1/2 Inch Steel

Welding half-inch steel can be a tough job. You need a MIG welder that’s strong and reliable. This guide will help you find the best one. We’ll look at what makes a good welder for thick metal and what to watch out for.

Key Features to Look For

When you’re buying a MIG welder for 1/2 inch steel, some features are more important than others.

- Amperage Output: This is how much power the welder has. For 1/2 inch steel, you’ll need at least 200 amps. More is better for faster welding and deeper penetration.

- Duty Cycle: This tells you how long the welder can run at a certain amperage before it needs to cool down. A higher duty cycle is crucial for working with thick steel. Look for something like 60% at 200 amps or more. This means it can weld for 6 minutes out of every 10 minutes at that power level.

- Wire Feed Speed Control: Good control over how fast the wire feeds helps you adjust for different metal thicknesses. This ensures a strong, clean weld.

- Voltage Control: Being able to adjust the voltage lets you fine-tune your weld. This is important for getting the right heat and preventing burn-through.

- Spool Gun Compatibility: Some welders can use a spool gun. This is a special tool that holds a small spool of wire. It’s great for welding aluminum, but can also be helpful for other metals.

- Portability: If you need to move your welder around a lot, consider its weight and size. Some powerful welders are quite heavy.

Important Materials and Build Quality

The materials and how the welder is put together matter a lot.

- Durable Casing: A strong metal casing protects the inner parts. It should be able to handle bumps and scrapes in a workshop or job site.

- Quality Internal Components: Look for welders with well-made transformers and circuit boards. These are the heart of the machine. Good quality parts mean the welder lasts longer and performs better.

- Robust Wire Feeder: The wire feeder needs to be strong and reliable. It pushes the welding wire through the gun. A metal feeder is usually better than plastic.

- Good Ground Clamp: A solid ground clamp makes sure you have a good electrical connection. This is essential for a good weld.

Factors That Improve or Reduce Quality

Several things can make a welder great or not so great.

- Brand Reputation: Well-known brands often have a history of making reliable equipment. They also usually offer good customer support and warranties.

- User Reviews: Reading what other people say about a welder is very helpful. Look for consistent positive feedback on performance and durability.

- Warranty: A good warranty shows the manufacturer stands behind their product. A longer warranty period is a sign of quality.

- Ease of Setup: A welder that’s easy to set up and start using is a big plus. You don’t want to spend hours figuring out complicated controls.

- Power Source Requirements: Make sure your power supply can handle the welder’s needs. A 200+ amp welder often needs a 230-volt outlet, which is different from a standard household outlet.

User Experience and Use Cases

How a welder feels to use and what you can do with it are important.

- Smooth Arc: A good MIG welder produces a smooth, stable arc. This makes it easier to control the weld puddle.

- Consistent Wire Feed: The wire should feed smoothly without jamming. This prevents interruptions and improves weld quality.

- Versatility: While you need it for 1/2 inch steel, can it also handle thinner metals? Many welders can do both, making them more useful.

- Common Uses: Welders strong enough for 1/2 inch steel are great for building custom car frames, heavy machinery repair, fabricating metal structures, and serious DIY projects.

Frequently Asked Questions (FAQ)

Q: What is the minimum amperage needed for 1/2 inch steel?

A: For 1/2 inch steel, you should aim for a MIG welder with at least 200 amps. More amperage will give you better results and weld faster.

Q: Is a higher duty cycle always better?

A: Yes, a higher duty cycle is crucial for welding thick steel like 1/2 inch. It means the welder can work for longer periods before needing to cool down, which is essential for continuous welding.

Q: Can I use a MIG welder meant for thinner metal on 1/2 inch steel?

A: It’s not recommended. Thinner metal welders often don’t have enough power (amperage) or the right features to properly fuse 1/2 inch steel. You risk weak welds or not being able to weld it at all.

Q: What kind of gas do I need for welding 1/2 inch steel?

A: For MIG welding steel, you typically use a shielding gas mixture. Common choices include 75% Argon and 25% CO2 (often called C25) or 100% CO2. Your welder’s manual will give specific recommendations.

Q: Do I need a spool gun for 1/2 inch steel?

A: A spool gun is not usually required for welding 1/2 inch steel with solid wire. However, if you plan to weld aluminum or very thin steel, a spool gun can be beneficial.

Q: How important is the wire feeder mechanism?

A: The wire feeder is very important. A smooth and consistent wire feed ensures a steady welding arc and good weld quality. Metal wire feeders are generally more durable than plastic ones.

Q: What voltage outlet do I need for a powerful MIG welder?

A: Welders designed for 1/2 inch steel often require a 230-volt power outlet. Standard household outlets are usually 115 or 120 volts. You may need an electrician to install the correct outlet.

Q: Can I weld stainless steel with a MIG welder meant for 1/2 inch mild steel?

A: While some MIG welders can weld different types of metal, you need to check the welder’s specifications. Stainless steel often requires specific gas mixtures and sometimes different welding parameters.

Q: What is a MIG welder’s “stick-out”?

A: “Stick-out” is the length of the welding wire that extends from the tip of the MIG gun to the surface of the metal being welded. Keeping a consistent stick-out helps maintain a stable arc and good weld penetration.

Q: How do I maintain my MIG welder for 1/2 inch steel?

A: Regular maintenance includes cleaning the contact tip, checking the wire feed rollers, inspecting the welding gun and cable for damage, and ensuring the gas flow is correct. Keeping the welder clean and dry also helps.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.