Ever tried to weld aluminum with TIG and ended up with a messy, bubbly weld instead of a clean, shiny one? You’re not alone. Choosing the right shielding gas for TIG welding aluminum can feel like navigating a maze, and picking the wrong one can lead to frustration, wasted time, and disappointing results.

Aluminum is a fantastic material, but it’s also a bit tricky to weld. It needs a specific gas to protect it from the air while you’re melting it. If you use the wrong gas, your weld can become weak, porous, or just plain ugly. This is where understanding your gas options becomes super important for anyone wanting to achieve strong, beautiful aluminum welds.

In this post, we’re going to break down exactly what you need to know. We’ll explore the different gases available, explain why they matter, and help you figure out which one is best for your specific aluminum welding projects. Get ready to say goodbye to welding headaches and hello to smooth, solid aluminum welds!

Our Top 5 Gas For Tig Welding Aluminum Recommendations at a Glance

Top 5 Gas For Tig Welding Aluminum Detailed Reviews

1. Aluminum TIG Welding Rod 3/32″x 16″ 1.8LB

Rating: 8.5/10

Get ready to weld like a pro with this Aluminum TIG Welding Rod! This rod is designed to make your aluminum welding projects easier and produce cleaner results. It’s a great choice for hobbyists and professionals alike who want reliable performance.

What We Like:

- The 5% added silicon helps the melted metal flow smoothly, making it easier to create strong, clean welds.

- It’s less likely to crack, which means fewer headaches and better-looking welds.

- You’ll experience a steady welding arc and very little messy splatter.

- This rod works with a wide range of aluminum types, including common ones like 6061 and 5052, and even some casting alloys.

- It comes in a convenient 1.8LB package.

- You can choose from different diameters (3/32″, 1/8″, 1/16″) to fit your specific needs.

What Could Be Improved:

- You’ll need to use a shielding gas, usually 100% Argon, Helium, or a mix, which is an extra item to have on hand.

This Aluminum TIG Welding Rod is a solid performer that helps you achieve excellent results on various aluminum projects. It’s a dependable choice for anyone looking to improve their TIG welding game.

2. YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB

Rating: 8.7/10

TIG welding aluminum can be tricky, but the YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB makes it much easier. This welding rod is a go-to choice for many welders because it’s reliable and works well for many jobs. It’s made with 5% silicon, which helps the melted metal flow smoothly. This makes it easier to create clean, strong welds. This rod is a great option for general aluminum welding.

What We Like:

- ER4043 is a very common and trusted aluminum welding wire.

- The silicon in the rod helps the weld pool flow nicely, making it easier to use.

- It’s less likely to crack when you weld, which means fewer problems.

- Welds made with this rod often look brighter and cleaner.

- It works on many different types of aluminum, including common grades like 6061 and 5052.

- It’s also good for welding aluminum castings and forged parts.

- The 5LB package gives you plenty of rod for your projects.

What Could Be Improved:

- This rod typically requires 100% Argon shielding gas, which is an extra cost if you don’t already have it.

- While it’s good for general use, very specific or high-strength aluminum might need a different rod.

Overall, the YESWELDER ER4043 welding rods are a solid choice for most aluminum TIG welding tasks. They offer good performance and versatility for welders of all skill levels.

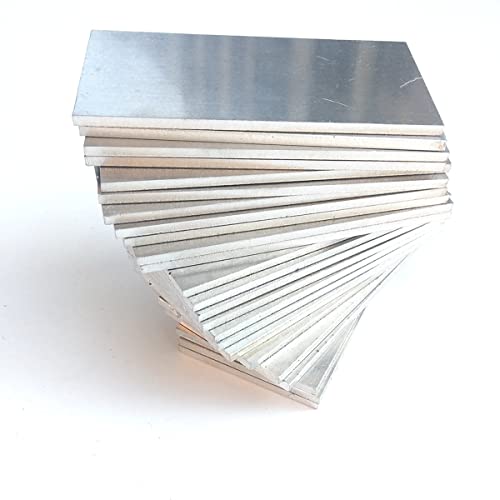

3. Biscuits Welding Practice Aluminum Parts- 5052 Aluminum – 2*4inch- 24Tablets-Very Suitable- Practice and Training for MIG

Rating: 8.7/10

Unlock your welding potential with these Biscuits Welding Practice Aluminum Parts. Made from high-quality 5052 aluminum, these 2×4 inch plates are your ideal training partners. You get 24 pieces in this pack, offering plenty of material to hone your skills. They are super useful for anyone learning to weld, whether you’re practicing MIG, TIG, stick, arc, gas welding, or brazing. Regular practice with these will make you a better welder and bring you lots of satisfaction.

What We Like:

- Excellent material: 5052 aluminum is great for practicing different welding types.

- Generous quantity: 24 pieces give you lots of welding opportunities.

- Perfect size: 2 inches by 4 inches is a convenient size for practice.

- Versatile: Works for MIG, TIG, Stick, Arc, Gas, and Brazing.

- Skill improvement: Helps beginners and experienced welders get better.

- Builds confidence: Continuous practice leads to happiness and better results.

What Could Be Improved:

- Thickness variation: While 0.125 inch is common, a few different thicknesses could offer more varied practice.

- Marking: Some clear markings or pre-drilled holes might help with specific training exercises.

These aluminum practice plates are a smart investment for any aspiring welder. They provide a reliable and plentiful surface to master your welding techniques and achieve your goals.

4. YESWELDER Aluminum TIG Welding Rod ER4043 1/16″x16″ 5LB

Rating: 8.5/10

If you’re looking for a reliable aluminum TIG welding rod, the YESWELDER ER4043 is a solid option. This rod is made with 5% silicon, which makes it a popular choice for many welding jobs. It’s an older, trusted type of welding wire that works well for general purposes. You’ll typically use it with 100% Argon shielding gas.

What We Like:

- The silicon in this rod helps the molten metal flow smoothly, making it easier to weld.

- It’s less likely to crack when you weld, giving you stronger joints.

- Welds made with this rod tend to be brighter and cleaner looking.

- It works well on many types of aluminum, including common ones like 3003 and 6061.

- It’s also good for welding cast aluminum parts.

- You can use it on materials that will be heat-treated later.

What Could Be Improved:

- While great for many jobs, ER4043 might not be the best choice for some high-strength aluminum alloys.

- For very demanding applications, you might need a different type of rod.

Overall, the YESWELDER ER4043 is a versatile and user-friendly welding rod that handles many common aluminum welding tasks with ease. It’s a great choice for hobbyists and professionals alike who need a dependable rod for everyday projects.

5. WeldingCity 2-Lb ER5356 TIG Welding Rod Aluminum 5356 3/32″ (2.4mm) x 36″ (914mm)

Rating: 8.6/10

The WeldingCity 2-Lb ER5356 TIG Welding Rod Aluminum 5356 3/32″ (2.4mm) x 36″ (914mm) | Pack of 2-Lb is a top-notch choice for anyone needing reliable aluminum TIG welding. These rods are made with premium quality ER5356 aluminum, meeting strict AWS A5.10/ASME SFA A5.10/ER5356 specifications. They are 36 inches long and come in a convenient 2-pound package. This rod is great for welding 5000 series aluminum, offering strong welds and good protection against saltwater corrosion. You’ll need shielding gas like Argon for best results.

What We Like:

- Premium quality ER5356 aluminum for strong, corrosion-resistant welds.

- Versatile for general-purpose, all-position TIG welding.

- Available in multiple diameters (1/16″, 3/32″, 1/8″) and package sizes (2-Lb, 5-Lb, 10-Lb) for different project needs.

- U.S. based supplier offers strong technical support and experienced customer service.

- Volume discounts encourage buying more to save money.

What Could Be Improved:

- Specific chemical composition details are provided, which is good, but the exact tolerances could be more clearly stated for advanced users.

This WeldingCity aluminum TIG welding rod is a solid performer for many aluminum welding jobs. Its quality and customer support make it a worthwhile investment for your workshop.

Choosing the Right Gas for TIG Welding Aluminum

TIG welding aluminum is a fantastic skill. It lets you create strong and clean welds. But to get the best results, you need the right gas. This guide will help you pick the perfect gas for your aluminum TIG welding projects.

What to Look For in Your Welding Gas

When you’re buying gas for TIG welding aluminum, a few things are super important.

Key Features to Look For:

- Purity: You want gas that is very clean. Even tiny bits of other stuff can mess up your weld. High purity means fewer problems.

- Type of Gas: For aluminum, you almost always use a noble gas. These gases don’t react easily.

- Flow Rate Control: You need to be able to control how much gas comes out. Too much or too little gas causes bad welds.

- Cylinder Size: Think about how much you’ll weld. Bigger tanks last longer but are heavier.

Important Materials and Why They Matter

The gas you choose is a critical material for your weld.

The Main Gas: Argon

Argon is the king of TIG welding gases, especially for aluminum. It’s a noble gas. This means it’s very stable and doesn’t want to mix with other elements. When you’re welding aluminum, argon creates a protective shield. This shield stops oxygen and other bad things from getting into your hot, melting metal. Oxygen makes aluminum welds weak and ugly.

Can You Mix Gases?

Sometimes, welders mix a little bit of helium with argon. This is called an argon-helium mix. Helium adds more heat to the weld puddle. This can help you weld thicker aluminum faster. It also makes the arc more stable. But, helium is more expensive than argon. For most jobs, pure argon is perfectly fine.

What Makes a Weld Good or Bad?

Many things can affect the quality of your aluminum TIG welds. The gas you use is a big one.

Factors That Improve Quality:

- Pure Argon: As we said, pure argon gives you a clean, strong weld. It helps remove oxides from the aluminum surface too.

- Correct Flow Rate: If you use the right amount of gas, it makes a good shield. This stops air pollution.

- Good Gas Lenses: These parts on your TIG torch help direct the gas flow better. They make a more focused shield.

Factors That Reduce Quality:

- Dirty Gas: If your gas tank or lines have dirt or moisture, it can get into your weld. This causes holes and weak spots.

- Too Little Gas: If not enough gas comes out, air can get to your hot metal. This makes the weld look rough and burnt.

- Too Much Gas: Using too much gas can actually pull in air from the sides. It can also make your arc unstable and hard to control.

- Using the Wrong Gas: Trying to weld aluminum with a gas meant for steel, like CO2, will not work well at all.

How You’ll Use It: User Experience and Use Cases

The gas you choose affects how easy and enjoyable your welding experience is.

User Experience:

When you have good gas, welding aluminum feels smoother. The arc is steady and easy to control. You see a nice, clean puddle that moves predictably. Cleaning up after welding is also easier because you have fewer defects. If you’re just starting, pure argon is the easiest to learn with. It’s forgiving and gives you great results.

Use Cases:

- Hobbyist Projects: Building custom bike frames, making decorative pieces, or repairing aluminum parts around the house. Pure argon is great for these.

- Automotive Repair: Welding aluminum parts like oil pans, intake manifolds, or body panels. You might use argon or an argon-helium mix for thicker parts.

- Marine Applications: Building or repairing aluminum boats and other marine equipment. These often need strong, corrosion-resistant welds, which pure argon helps achieve.

- Aerospace: While more advanced, aerospace welding often uses argon with precise helium additions for critical components.

Choosing the right gas is a simple step that makes a huge difference in your aluminum TIG welding. Stick with pure argon for most jobs, and consider adding helium for thicker materials if you need extra heat.

Frequently Asked Questions About Welding Gas for Aluminum

Here are some common questions people have about choosing gas for TIG welding aluminum.

Q: What is the best gas for TIG welding aluminum?

A: The best gas for TIG welding aluminum is pure Argon. It creates a clean shield and works very well.

Q: Can I use a gas mix for aluminum?

A: Yes, you can use an argon-helium mix. Helium adds more heat and can help you weld thicker aluminum faster.

Q: Why is Argon good for aluminum?

A: Argon is a noble gas. It forms a protective shield around the weld puddle. This stops oxygen and other bad things from getting into the hot metal.

Q: What happens if I use too little gas?

A: If you use too little gas, air can get to your hot weld. This makes the weld weak and look bad.

Q: What happens if I use too much gas?

A: Using too much gas can actually pull in air from the sides. It can also make your welding arc unstable.

Q: How do I know what flow rate to use?

A: The right flow rate depends on your torch, the size of the cup, and how windy it is. A good starting point for pure argon is often between 15-25 cubic feet per hour (CFH).

Q: Do I need a special regulator for welding gas?

A: Yes, you need a flowmeter regulator. This attaches to your gas cylinder and lets you set and control the gas flow rate precisely.

Q: Can I use the same gas for steel and aluminum?

A: No. For steel, you often use mixes with CO2 or Argon/CO2. For aluminum, pure Argon or Argon/Helium is best.

Q: Where can I buy welding gas?

A: You can buy welding gas from welding supply stores, industrial gas suppliers, or sometimes from larger hardware stores.

Q: How often do I need to change my gas cylinder?

A: You change your cylinder when it’s empty. How long it lasts depends on the size of the tank and how much gas you use.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.