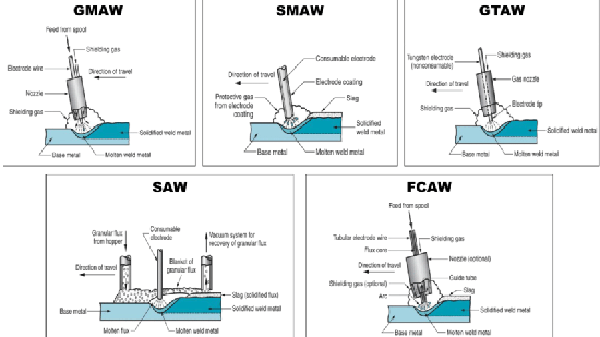

Whether you’re a beginner welder or just looking to expand your knowledge in the field, understanding the different types of welding is essential. From Flux-Cored Arc Welding (FCAW) to Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), Shielded Metal Arc Welding (SMAW), and Submerged Arc Welding (SAW), each method has its unique characteristics and applications. In this article, we’ll delve into the common types of welding and explore their advantages and limitations.

Photo by researchgate

FCAW (Flux-Cored Arc Welding)

Flux-Cored Arc Welding (FCAW), also known as “wire welding,” is a widely used welding process that offers high versatility and is suitable for both thick and thin materials.

This method utilizes a continuously-fed consumable electrode, which contains flux and provides the shielding gas needed to protect the weld pool from atmospheric contamination. FCAW can be performed with or without the use of external shielding gas, depending on the specific application.

One of the advantages of FCAW is its ability to penetrate through rust, dirt, and other contaminants, making it ideal for outdoor and construction projects.

FCAW produces high-quality welds with excellent strength and good impact resistance. It is commonly used in shipbuilding, structural steel fabrication, and pipeline welding. FCAW can produce more smoke and fumes compared to other welding methods, requiring proper ventilation and safety precautions.

GMAW (Gas Metal Arc Welding)

Gas Metal Arc Welding (GMAW), also known as Metal Inert Gas (MIG) welding, is a popular welding technique that uses a consumable wire electrode and a shielding gas to create an arc between the electrode and the workpiece. GMAW is known for its versatility, ease of use, and ability to produce clean and visually appealing welds.

One of the main advantages of GMAW is its high welding speed, making it suitable for projects that require efficiency. It can be used on a wide range of materials, including carbon steel, stainless steel, and aluminum. GMAW also allows for better control over the weld pool, resulting in minimal spatter and reduced post-weld cleaning.

GMAW may not be suitable for welding thick materials due to its lower penetration capabilities. It also requires the use of shielding gas, which adds to the overall cost of the welding process. GMAW is commonly used in automotive, manufacturing, and fabrication industries.

Image by waybuilder

GTAW (Gas Tungsten Arc Welding)

Gas Tungsten Arc Welding (GTAW), often referred to as Tungsten Inert Gas (TIG) welding, is a precise and meticulous welding process that produces high-quality welds. GTAW uses a non-consumable tungsten electrode and a shielding gas to protect the weld area from atmospheric contamination.

One of the key advantages of GTAW is its ability to weld a wide range of materials, including stainless steel, aluminum, copper, and exotic metals. It produces welds with excellent visual appearance, minimal spatter, and high strength. GTAW also allows for precise control over the heat input, resulting in minimal distortion and warping of the workpiece.

GTAW requires a higher level of skill and experience compared to other welding methods. It is a slower process and may not be suitable for high-speed production. GTAW is commonly used in aerospace, nuclear, and food processing industries, where weld quality and aesthetics are of utmost importance.

SMAW (Shielded Metal Arc Welding)

Shielded Metal Arc Welding (SMAW), also known as stick welding, is a versatile and portable welding method that utilizes a consumable electrode coated with flux. The flux coating provides both shielding gas and a slag layer to protect the weld pool from atmospheric contamination.

SMAW is known for its simplicity and can be performed in various positions, making it ideal for outdoor and rugged conditions. It is commonly used in construction, maintenance, and repair applications. SMAW can be used on a wide range of materials, including carbon steel, stainless steel, and cast iron.

One of the advantages of SMAW is its ability to penetrate through rust, paint, and other surface contaminants, making it suitable for welding in less-than-ideal conditions. SMAW has a lower deposition rate compared to other welding methods, resulting in slower welding speeds.

It also requires frequent electrode changes and produces more spatter. Proper safety precautions, such as wearing protective clothing and using adequate ventilation, are essential when performing SMAW.

Image by hunkmachining

SAW (Submerged Arc Welding)

Submerged Arc Welding (SAW) is a welding process that utilizes a continuously-fed consumable electrode and a granular flux. The flux is poured over the welding area, creating a protective blanket that shields the arc and weld pool from atmospheric contamination.

SAW is commonly used for welding thick materials and is known for its high deposition rates, resulting in increased productivity. It is often employed in large-scale projects, such as the construction of ships, bridges, and pressure vessels. SAW produces welds with excellent quality and structural integrity.

One of the advantages of SAW is its ability to create deep welds with excellent penetration. It also produces minimal spatter and fumes, making it a relatively clean welding process. SAW requires specialized equipment, making it less portable compared to other welding methods. The use of granular flux also adds to the overall cost of the welding process.

Pros and Cons of Each Welding Type

FCAW:

Pros:

- Versatile and suitable for both thick and thin materials

- High-quality welds with excellent strength and impact resistance

- Can penetrate through rust and contaminants

Cons:

- Produces more smoke and fumes compared to other methods

- Requires proper ventilation and safety precautions

GMAW:

Pros:

- Versatile and easy to use

- High welding speed and efficiency

- Produces clean and visually appealing welds

Cons:

- Not suitable for welding thick materials

- Requires the use of shielding gas, adding to the cost

GTAW:

Pros:

- Precise and meticulous welding process

- Suitable for a wide range of materials

- Produces high-quality welds with minimal distortion

Cons:

- Requires a higher level of skill and experience

- Slower welding process compared to others

SMAW:

Pros:

- Versatile and portable, ideal for outdoor and rugged conditions

- Can penetrate through surface contaminants

- Suitable for a wide range of materials

Cons:

- Lower deposition rate and slower welding speeds

- Requires frequent electrode changes and produces more spatter

SAW:

Pros:

- High deposition rates, resulting in increased productivity

- Suitable for welding thick materials and large-scale projects

- Produces welds with excellent quality and structural integrity

Cons:

- Requires specialized equipment, less portable

- Use of granular flux adds to the overall cost

Choosing the Right Welding Type for Your Project

When selecting the appropriate welding method for your project, several factors should be considered, including the type and thickness of the material, desired weld quality, project timeline, and available resources. Each welding type has its own strengths and limitations, so it’s essential to assess your specific requirements and goals.

Image by fractory

For example, if you’re working on a construction site and need to weld thick materials, FCAW or SAW may be suitable options due to their high penetration capabilities. On the other hand, if you prioritize visual appearance and cleanliness, GMAW or GTAW might be more appropriate.

It’s also crucial to evaluate your skill level and experience with different welding methods. Some techniques, such as GTAW, require more advanced skills and precise control, while others, like SMAW, are more forgiving and can be learned relatively quickly.

Consulting with experienced welders or professionals in the industry can provide valuable insights and guidance in choosing the right welding type for your project. Additionally, conducting thorough research and considering the specific requirements of your application will help ensure successful welds and project outcomes.

Welding Safety Precautions

Welding can be a hazardous process, and proper safety precautions should always be followed to protect yourself and others in the vicinity. Here are some essential safety measures to consider:

Personal Protective Equipment (PPE)

Wear appropriate PPE, including a welding helmet, safety glasses, welding gloves, flame-resistant clothing, and steel-toed boots.

Adequate Ventilation

Ensure proper ventilation in the welding area to minimize exposure to welding fumes and gases. Welding in an enclosed space should be avoided whenever possible.

Fire Prevention

Keep a fire extinguisher nearby and clear any flammable materials from the welding area. Be cautious of sparks and hot workpieces that may ignite surrounding objects.

Electrical Safety

Ensure that the welding equipment is properly grounded and follow electrical safety guidelines to prevent electrical shock or fire hazards.

Conclusion

Understanding the common types of welding is crucial for welders of all levels. From Flux-Cored Arc Welding (FCAW) to Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), Shielded Metal Arc Welding (SMAW), and Submerged Arc Welding (SAW), each method offers its own unique advantages and limitations.

By familiarizing yourself with these different welding types, you can better comprehend which one suits your specific needs and make informed decisions in your industry. Whether you’re working on construction projects, automotive applications, or precision welding, choosing the right welding method can significantly impact the quality and efficiency of your work.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.