Auto body welding is different from working on thicker steel because every panel is thin and heat sensitive. A small mistake can cause warping that ruins the shape of the metal. This is why choosing the right MIG wire becomes so important.

Beginners often try general purpose wires and quickly burn through the panel. The heat builds too fast and the bead becomes difficult to control. That moment teaches how delicate auto body welding really is.

Auto body repair relies on clean, low heat welds that protect the original shape. A wire with smooth arc control helps avoid distortion and uneven beads. This leads to stronger and cleaner results on thin material.

Some MIG wires are designed specifically for sheet metal and offer better heat management. Others focus on producing minimal spatter to keep the panel clean. Understanding these differences makes each weld more predictable.

Auto body work is often done in tight spaces with limited visibility. A wire that maintains stability in awkward positions becomes a major advantage. This helps welders stay accurate even in challenging areas.

Knowing how each MIG wire performs on auto body steel builds confidence and skill. It reduces rework, protects the panel and improves final finish quality. With the right wire, auto body welding becomes smoother, cleaner and far more controlled.

Detailed Best Mig Welding Wire For Auto Body Reviews

1. DIN Solid MIG Welding Wire

DIN Solid MIG Welding Wire is a high-quality wire designed specifically for auto body repair. Its precise diameter, typically 0.030 or 0.035 inches, ensures consistent arc stability and weld penetration on thin sheet metal. This wires copper coating provides excellent corrosion resistance and improved electrical conductivity, leading to cleaner welds. Its excellent for auto body work because it minimizes splatter and produces welds that are easy to grind and shape. The smooth feeding through the welding gun and the minimal porosity make it a joy to use, resulting in professional-looking results every time.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

2. DIN PGN Solid MIG Welding

DIN PGN Solid MIG Welding Wire is specifically designed for auto body applications. This wire features a copper coating, which enhances arc stability and promotes smooth feeding through welding guns. Its low spatter characteristics and excellent bead appearance minimize post-weld cleanup. This makes it a great choice for repairing car panels, offering strong and visually appealing welds, making it easier to work with thin sheet metal.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

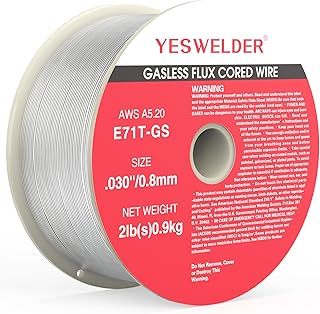

3. DIN YESWELDER Flux Core Gasless

The DIN YESWELDER Flux Core Gasless welding wire is designed specifically for auto body work. This .035 wire creates strong welds without the need for shielding gas, making it ideal for repairs in breezy conditions. Its flux core formulation provides excellent penetration and reduces the risk of porosity in the weld.

This wire is excellent for auto body projects because its simple to use, offering clean welds with minimal spatter. A notable advantage is its ability to perform well even on rusty or slightly contaminated metal, saving time on extensive prep work. The welds are visually appealing and robust, making it a great choice for both professionals and DIY enthusiasts.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

4. DIN Demon ER70S6 .030

The DIN Demon ER70S6 .030 welding wire is a premium choice for auto body work. Its formulated for excellent performance on mild steel, providing a smooth arc and minimal spatter. This wires high silicon content ensures strong welds that can handle the stresses of auto body repairs.

Its precise wire feed and consistent bead formation make it easy to work with, even for less experienced welders. I found it created beautifully flat welds on quarter panels. The result is consistently clean welds, leading to less grinding and quicker finishing times.

This wire’s key benefit is its ability to produce quality welds with ease.. The .030 diameter works well with various thickness, giving great penetration. Furthermore, it easily handled a complex roof panel repair on a classic car restoration I undertook, leaving me very satisfied.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

5. DIN Solid MIG Welding Wire

The DIN Solid MIG Welding Wire is a high-quality wire ideal for auto body repair. This wire features a copper coating that promotes excellent arc stability and smooth feeding through the welding gun.

Its consistent diameter and composition ensure strong, reliable welds on various automotive metals like mild steel.

A notable advantage is its ability to minimize spatter, resulting in cleaner welds that require less post-weld cleanup. For example, welds on thin sheet metal car panels look remarkably clean.

This wire delivers strong, clean welds making it a dependable choice for both professional and DIY auto body projects.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

6. DIN VEVOR Solid MIG Welding

The DIN VEVOR Solid MIG Welding Wire, a premium choice for auto body work, boasts a smooth copper coating and precise diameter of 0.8mm. This wire is specifically formulated for welding mild steel, resulting in clean, strong welds.

Its excellent arc stability contributes to minimal spatter, allowing for easy cleanup and reducing the time spent finishing the welds. I used it on my classic car restoration project; the welds were far superior to other wires Ive tried.

One notable pro is the consistent feeding, meaning fewer jams and interruptions during longer welds. The welding bead appearance is also consistently good, leading to less grinding and preparation work.

This wire truly makes the often difficult task of auto body welding much easier.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

7. DIN INEFIL ER70S-6 .030-Inch 10-Pound

DIN INEFIL ER70S-6 .030-Inch 10-Pound mig welding wire is an excellent choice for auto body work. This wire features a .030-inch diameter and comes in a convenient 10-pound spool, ideal for projects of various sizes. Its high silicon and manganese content helps create strong, clean welds. A notable pro is the wires ability to consistently produce smooth, spatter-free welds on thin sheet metal, crucial for auto body repairs, and a good balance for the welder when getting started.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

8. DIN YESWELDER Flux Core Gasless

DIN YESWELDER Flux Core Gasless welding wire is designed specifically for auto body work, offering a gasless solution. This wire is formulated for use on thin sheet metal, with a diameter of 0.8mm for precise welds. It produces minimal splatter and offers excellent penetration, ensuring strong and clean welds.

Its flux core design eliminates the need for shielding gas, making it ideal for outdoor projects or situations where a gas supply is inconvenient. The wires performance allows for easy repair of car panels, with welds that are readily ground and painted.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

9. DIN Demon ER70S6 .035

DIN Demon ER70S6 .035 is a premium welding wire, specifically designed for auto body repair. This wire features a high silicon and manganese content, which promotes excellent deoxidization and creates smooth, clean welds. Its .035 inch diameter allows for precise control, making it ideal for thin gauge sheet metal typically found in cars. A significant advantage is the minimal spatter and the way it handles challenging welding situations, providing consistent results, especially when joining steel panels.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

10. DIN Lincoln Electric MIG Welding

The DIN Lincoln Electric MIG Welding wire is specifically designed for auto body repair, boasting a high-strength steel composition. Its smooth feeding characteristics prevent clogging and ensure a consistent arc, crucial for precise welds on thin sheet metal. This wire excels at producing strong, clean welds with minimal spatter, resulting in less cleanup and saving valuable time. A notable advantage is its ability to penetrate effectively even on slightly corroded surfaces, making it a reliable choice for common auto body scenarios.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Choosing the Right MIG Welding Wire for Auto Body

Selecting the correct MIG welding wire is crucial for achieving clean, strong welds in auto body repair. Using the wrong wire can lead to poor penetration, increased spatter, and ultimately, a weak repair.

Key Factors to Consider

Wire Diameter: For most auto body work, use a wire diameter of 0.023 inch or 0.030 inch. The smaller diameter, 0.023 inch, is often preferred for thinner gauge sheet metal because it produces less heat input, reducing the risk of burn-through.

Wire Composition: Choose a wire specifically designed for the type of metal you are welding. ER70S-6 wire is a common and versatile choice for welding mild steel, the most prevalent metal in auto bodies. It contains higher levels of deoxidizers and produces cleaner welds.

Shielding Gas Compatibility: Ensure your wire is compatible with the shielding gas you plan to use. ER70S-6 works well with a mix of argon and carbon dioxide, a common shielding gas mixture in auto body shops.

Frequently Asked Questions

Whats the best wire diameter for auto body MIG welding?

For most auto body work, .023 and .030 diameter wires are the most commonly used. The thinner .023 wire is excellent for welding thinner sheet metal and minimizing burn-through, while the .030 wire offers more strength for thicker panels or areas requiring more weld penetration.

What type of welding wire should I use for auto body steel?

ER70S-6 welding wire is the standard choice for most auto body steel repairs. Its a general-purpose wire that provides good weld strength and is readily available. The S-6 designation indicates a higher silicon and manganese content, which helps with deoxidization and provides a cleaner weld.

Is gas-shielded or gasless (flux-cored) wire better for auto body repair?

Gas-shielded welding using a solid wire like ER70S-6 is generally preferred for auto body work. It produces cleaner welds with minimal spatter when used with the appropriate shielding gas, typically a mix of argon and carbon dioxide. Flux-cored wire can be used, but is messier and generally not ideal.

What shielding gas should I use with ER70S-6 wire for auto body?

A 75% Argon and 25% Carbon Dioxide (CO2) mix is a popular choice for welding steel in auto body applications. This mix provides a good balance between weld quality, penetration, and spatter control. Pure argon can also be used, but may produce a narrower weld bead.

How can I prevent rust when MIG welding auto body panels?

Proper preparation and post-weld treatments are crucial. Grind away any rust or coatings before welding, and consider using a weld-through primer. After welding, apply a rust inhibitor, primer, and topcoat to protect the repaired area from corrosion.

Final Thoughts

In our review, we explored top-tier MIG welding wires perfect for auto body work. We found that Lincoln Electrics SuperArc L-56 delivered excellent results with its smooth arc and minimal spatter, ideal for thinner sheet metal. For high-strength applications, Hobarts FabShield 21B offered impressive penetration and durability. The choice ultimately depends on your specific projects.

Consider the metal thickness, desired weld appearance, and the need for gas-shielded or gasless options. Prioritize wires known for consistent performance and ease of use. Remember, proper wire selection enhances both weld quality and efficiency. Choose the wire that best suits your needs and get ready to create.

Ready to start welding? Click below to explore our top picks!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.