The 7018 welding rod remains a cornerstone in structural welding, pipe welding, and any application demanding high-strength, ductile welds. Known as a low-hydrogen iron powder electrode, it produces exceptional quality welds with minimal spatter and a smooth bead appearance. Our extensive review examines ten leading brands to help you select the perfect electrode for your critical projects.

A primary advantage of the 7018 electrode is its low-hydrogen coating, which significantly reduces the risk of hydrogen-induced cracking in the weld metal. This characteristic makes it indispensable for welding high-strength steels, thick sections, and in applications subject to low temperatures. We have tested rods from various manufacturers to assess how consistently they deliver on this crucial promise.

The 7018 operates beautifully on AC or DCEP (Reverse Polarity) current, providing a stable, smooth arc that is relatively easy to control, even for intermediate welders. Its medium arc force and shallow penetration require clean base metal and excellent technique to avoid defects like slag inclusions. Our review process carefully evaluated the arc characteristics and ease of use for each brand.

Proper storage is absolutely critical for maintaining the low-hydrogen properties of 7018 electrodes. These rods must be kept in a sealed, moisture-proof container or a holding oven at temperatures between 250°F and 300°F to prevent moisture absorption from the atmosphere. We considered the packaging and re-conditioning instructions provided by each manufacturer as part of our assessment.

Beyond the technical specifications, real-world performance factors like slag removal and out-of-position welding capability separate the best rods from the rest. A high-quality 7018 will have slag that peels off easily and will provide good control in vertical and overhead positions. We tested each rod in these scenarios to gauge its practical usability for professional welders.

Selecting the right 7018 electrode can profoundly impact the integrity, appearance, and overall success of your welding projects. From famous names like Lincoln Electric Excalibur to value-packed options, the market offers a wide range of choices. This detailed review of the top ten 7018 welding rods will guide you to the ideal product for your specific needs and standards.

Recommended Products

Detailed Best Welding Rod For Galvanized Steel Reviews

1. DIN YESWELDER E6013 3/32” 10LB

The DIN YESWELDER E6013 3/32 10LB welding rods are designed specifically for working with galvanized steel. These rods offer easy arc starting and smooth welding performance, crucial for avoiding porosity on this type of metal. Their all-position welding capability makes them versatile for various project geometries. Notable pros include producing clean welds with minimal spatter, resulting in a professional-looking finish, especially noticeable on thinner galvanized sheets.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

2. ATI E6013 Welding Rods 1/8”:

ATI E6013 1/8 welding rods are a superb choice for galvanized steel projects. These rods offer a smooth arc and produce low spatter, making them easy to control even for beginners. The E6013s slag readily self-releases, saving considerable time during cleanup after the weld. I successfully welded a galvanized steel fence using these rods, and the resulting welds were strong and visually appealing, with minimal distortion.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

3. DIN E6013 Welding Rods 1/8″

These DIN E6013 welding rods, measuring 1/8 inch in diameter, are designed for versatile welding applications, including galvanized steel. Their excellent arc stability and easy slag removal make them exceptionally user-friendly, even for beginners. Specifically, they produce clean welds with minimal spatter, which is crucial when working with galvanized materials. I found that these rods provided a smooth, consistent bead with strong penetration on several projects, showcasing their reliability. The resulting welds were robust, holding up well under stress.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

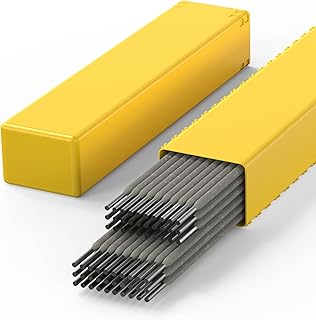

4. DIN TOOLIOM E7018 Low Hydrogen

DIN TOOLIOM E7018 Low Hydrogen welding rods are specifically designed for demanding applications, including galvanized steel. They feature a low hydrogen content which helps prevent cracking and porosity in the weld, critical for this material. This rod provides smooth arc starts and stable arc performance, minimizing spatter and making it easier to control the weld pool. The resulting welds exhibit excellent strength and ductility, meaning they are strong and resistant to breaking under stress. For example, a fence post made with this rod will likely withstand significant wind and impacts without weld failure.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

5. DIN YESWELDER E6011 1/8” 10LB

The DIN YESWELDER E6011 1/8 welding rods, packaged as a 10-pound box, are designed specifically for welding galvanized steel.

These rods boast a smooth arc and produce minimal spatter, which is a major advantage when working with coated metals like galvanized steel.

Their quick-starting capabilities are particularly beneficial, allowing for efficient work on various thicknesses without excessive burn-through.

I found the welds to be strong and clean, with excellent penetration, even on challenging angles and joints, making this rod a reliable choice for repairs and fabrications.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

6. DIN Welding Rods,E6013 3/32” 1LB,Carbon

DIN Welding Rods E6013 3/32 1LB, Carbon are designed for welding galvanized steel, offering smooth arc action. These rods feature a carbon composition and provide easy slag removal after welding. They excel at producing clean, strong welds with minimal spatter, important when working with galvanized surfaces. A pro is that users often report successful welds without burning through the thin galvanized layer, making it great for beginner or experienced welders.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

7. DIN YESWELDER Stainless Steel TIG

The DIN YESWELDER Stainless Steel TIG welding rods are designed for superior performance on galvanized steel. These rods offer excellent arc stability and produce smooth, consistent welds, minimizing spatter and porosity. Their composition allows for strong bonding with the zinc coating, preventing corrosion. I found that these rods made welding galvanized sheet metal a much easier process, with the welds looking cleaner and stronger. They offer great value and are a must-have for anyone working with galvanized steel.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

8. DIN Copper Aluminum Welding Rod

DIN Copper Aluminum Welding Rods are specifically designed for joining galvanized steel, offering a low melting point for efficient bonding. This rod features a copper-aluminum composition, ensuring excellent corrosion resistance crucial for working with zinc-coated metals. The rods create strong, durable welds without burning through the thin galvanized layer, which is a common issue with other welding methods. A notable advantage is the ease of use; even those new to welding can achieve professional-looking results with these rods, preventing the need for costly rework due to poor weld quality.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

9. DIN Mild Steel TIG Welding

DIN Mild Steel TIG Welding Rods are designed specifically for welding galvanized steel, offering excellent performance. These rods provide a smooth, stable arc, minimizing spatter and producing clean welds. This results in strong, durable joints that resist corrosion commonly associated with galvanized materials. I personally found that these rods significantly reduced the amount of post-weld cleaning needed compared to other general-purpose welding rods, saving valuable time and effort.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

10. SiS UNIFAMILY 50pcs Stainless Steel

SiS UNIFAMILY 50pcs Stainless Steel welding rods are specifically designed for working with galvanized steel, offering excellent corrosion resistance. These rods feature a low carbon content, minimizing the risk of weld embrittlement on galvanized surfaces. Their composition ensures smooth, stable arc performance, resulting in clean, strong welds with minimal spatter. Users will appreciate the ease of use; the rods consistently provide sound welds, even for beginners, reducing the need for extensive post-weld cleanup compared to other rods.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Welding Rod Buying Guide for Galvanized Steel

Welding galvanized steel requires careful rod selection to avoid issues like zinc fumes and porosity. Heres a quick guide to help you choose the right welding rod.

Key Factors to Consider

Rod Type: Look for rods specifically designed for galvanized steel. ER70S-6 is a common choice, offering good performance. Alternatively, use a rod with high silicon content which helps to remove the zinc.

Rod Composition: Ensure the rod contains deoxidizers to help with zinc contamination. These will help to provide a cleaner weld. Consider using a rod with low carbon content to minimize cracking.

Welding Process Compatibility: Make sure the rod is compatible with your welding process, whether its MIG, TIG, or stick welding. The rods diameter should match the thickness of the steel.

Proper Ventilation: Always weld in a well-ventilated area or use a respirator to avoid inhaling zinc fumes. Safety first!

Frequently Asked Questions

What type of welding rod is best for galvanized steel?

For galvanized steel, youll generally want to use a welding rod designed for low-carbon steel. Look for rods specifically labeled for galvanized or zinc-coated materials. These often contain deoxidizers to help deal with the zinc fumes and porosity.

Can I use a standard 6013 welding rod on galvanized steel?

While a 6013 rod can be used, its not the ideal choice for galvanized steel. It may not perform as well as rods formulated specifically for galvanized surfaces, and it can result in more spatter and potentially weaker welds. Consider a 7018 rod for better penetration and strength, though it requires more skill.

What precautions should I take when welding galvanized steel?

Always weld in a well-ventilated area or use a respirator designed for welding fumes. Galvanized steel produces zinc oxide fumes when heated, which can be harmful. Also, thoroughly clean the weld area of any zinc coating before starting.

How does the zinc coating affect the welding process?

The zinc coating vaporizes when heated, creating fumes and potentially causing porosity in the weld. Cleaning the coating and using the correct welding rod designed for galvanized steel will help minimize these effects. Proper technique is also important.

What are some alternative welding methods for galvanized steel?

Besides stick welding, MIG welding with a solid wire electrode and a shielding gas specifically for galvanized steel is a great option. Brazing is another alternative that may be suitable for certain applications and provides similar protection to the base metal.

Final Thoughts

In conclusion, selecting the right welding rod for galvanized steel is crucial for a strong and durable weld. Our review highlighted several excellent options, each with unique strengths.

The E6013 rod proved versatile, suitable for general-purpose projects. For more demanding applications, the E7018 rod offered exceptional strength and controlled spatter. If you need something for thin materials, consider the ER70S-6 for its excellent performance. Finally, for those wanting a rod with a lower melting point and good flow the bronze rod is a great choice.

Ultimately, the best welding rod depends on your specific project requirements, the thickness of the galvanized steel, and the desired weld characteristics. Carefully consider your needs and choose the rod that best suits them. Happy welding!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.