Ready to tackle that welding project in your garage? Finding the right welding rod is key, and it can feel overwhelming with all the options out there. That’s why we’ve gone hands-on, actually welding with different rods to bring you some real-world advice.

So, what should you look for? The best welding rod for home use balances ease of use, material compatibility, and, of course, a good weld. Well help you navigate the common types: E6011 for general purpose and rusty metal, E6013 offering smooth welds and good looks, and E7018 for strength. Well cover the specific projects each is best for, making your choice simple. Lets get to it and help you choose the best welding rod for your needs!

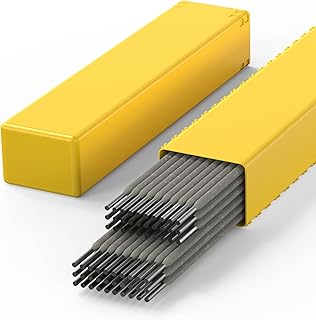

Recommended Products

Detailed Best Welding Rod For Home Use Reviews

1. DIN YESWELDER E6013 3/32” 10LB

The DIN YESWELDER E6013 3/32 10LB welding rods are a great choice for home use. These rods offer a smooth arc, resulting in easy starts and consistent welds even for beginners. Theyre designed for use on a variety of steel thicknesses, making them versatile for common household projects. One of their strongest pros is their ability to produce clean welds with minimal spatter, leaving less cleanup required after welding. I successfully repaired a garden gate using these rods, and the welds held strong.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

2. ATI E6013 Welding Rods 1/8”:

ATI E6013 welding rods, 1/8, are ideal for home use. These rods feature a slag that is easy to remove and offer a smooth arc, making them user-friendly for beginners. They work well with general purpose steel, providing strong and dependable welds. A significant advantage is the ability to produce clean welds, as demonstrated when repairing a garden gate, with minimal spatter.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

3. DIN Saker E6013 Welding Rod

DIN Saker E6013 welding rods are a solid choice for home welders. These rods offer easy arc starting and smooth welding, producing clean welds in various positions. Specifically, they work well on mild steel, making them suitable for many common projects. The slag is easily removable, and the welds appear cosmetically pleasing, resulting in less cleanup time. This translates to efficient and enjoyable welding experience, perfect for beginners and DIY enthusiasts looking for reliable results.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

4. ATI YESWELDER E6013 3/32″(2.5lb)+1/8″(2.5lb) Weldi…

ATI YESWELDER E6013 welding rods offer versatility for home projects with two popular sizes: 3/32 and 1/8. These rods are designed for general-purpose welding of mild steel, providing a smooth arc and easy slag removal. Their user-friendly nature makes them perfect for beginners, allowing for consistent and clean welds, even on thinner materials. A key benefit is the ability to create strong, visually appealing welds, making them ideal for everything from small repairs to crafting.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

5. DIN 200Amp Welding Machine Rods,

DIN 200 Amp Welding Machine Rods are designed for home welders, featuring a 2.5mm diameter and a consistent amperage range up to 200 amps. These rods provide a smooth arc and easy slag removal, making them excellent for beginners and experienced DIYers.

This welding rod is beneficial for its user-friendliness; it provides consistent and controlled welds, which reduces the chance of defects. The rods create clean and strong welds on various metal projects.

A notable pro is the ease of use, as it reduces the learning curve for beginners while still being suitable for intricate projects. It creates clean and strong welds on mild steel.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Welding Rod Buying Guide for Home Users

Choosing the right welding rod is essential for successful home projects. Heres a quick guide to help you:

Material Compatibility

The type of metal youre welding dictates your rod choice. For example, use E6013 rods for general-purpose welding on mild steel. If you are working on cast iron, you will want to select an appropriate rod for that specific material. Always confirm rod compatibility with your base metal.

Welding Process

Consider your welding process. For Stick welding (SMAW), youll need appropriately coated rods. If youre using a MIG welder with a spool gun attachment, you will be using a wire spool. For TIG (GTAW) welding, you will need filler metal rods. Ensure your rod type matches your welder.

Rod Diameter

Rod diameter impacts penetration and the amount of material deposited. Start with smaller diameter rods, such as 1/16 inch or 3/32 inch, as they are easier to control. Thicker rods can be used as you gain more experience and working on thicker metals.

Frequently Asked Questions

Whats the best welding rod for general home repairs?

For general home repairs, E6013 welding rods are a great choice. They are easy to use, work well with various thicknesses of steel, and create smooth welds. This versatility makes them suitable for a wide range of projects around the house.

Can I use the same welding rod for all types of metal?

No, you cant. Different metals require different welding rods. For instance, E6013 is commonly used for mild steel, while other rods are needed for stainless steel or aluminum.

What size welding rod should I buy for a beginner?

A 1/8-inch diameter welding rod is a good size for beginners. This size offers a good balance of usability and strength, allowing you to easily control the weld pool. It is also suitable for many common home projects.

How do I choose the right welding rod based on the projects metal thickness?

The thickness of the metal determines the amperage youll need, which in turn influences the welding rod size. For thinner metals, like sheet metal, youll need a smaller diameter rod and lower amperage settings to prevent burn-through. Thicker metals, like those used in structural applications, require a larger rod and higher amperage.

What are the key differences between E6011 and E6013 welding rods?

E6011 rods are known for deeper penetration and are often used for welding through rust or painted surfaces. E6013 rods are easier to use, create cleaner welds, and are preferred for their ease of use, especially for beginners. The choice depends on the specific project requirements and the condition of the metal being welded.

Final Thoughts

In conclusion, choosing the best welding rod for your home projects depends heavily on the materials youre working with and the type of welding youll be doing. For general steel work, 6011 rods are a solid and versatile choice. If youre tackling thicker steel or require stronger welds, 7018 rods provide excellent strength and are known for their smooth arc. Finally, for projects with thinner metals, consider using 6013 rods, which offer ease of use and good performance.

Ultimately, consider the size of your projects and what materials youll be joining. Review the different rod types mentioned and choose the one that aligns best with your needs and skill level. Now, pick up your preferred welding rods and get welding!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.