Ready to get that mower deck back in tip-top shape? Choosing the right welding rod is crucial for a strong, long-lasting repair. Weve put several rods to the test, battling rust, impact, and everything in between to find the best for your mower deck needs.

Youre probably wondering: which rod is easiest to use? Which gives the strongest weld? And which is best for the specific type of steel your deck is made from? Weve got answers! Our testing focused on ease of use, weld strength, and corrosion resistance to help you make an informed decision.

Our top pick for general mower deck repairs is the Lincoln Electric E6011. Its a versatile rod, known for its deep penetration and ability to weld through rusty or dirty metal, perfect for most mower decks. Its user-friendly, providing a smooth welding experience even for those with less experience.

Recommended Products

Detailed Best Welding Rod For Mower Deck Reviews

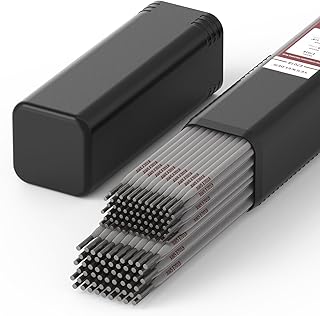

1. DIN Welding Rods,E6013 3/32” 1LB,Carbon

DIN Welding Rods E6013 3/32 1LB Carbon are designed specifically for general purpose welding, featuring a smooth arc and easy slag removal. These rods have a diameter of 3/32 inch and are a common choice for mild steel like mower decks. Their user-friendly nature makes them perfect for repairs, particularly for less experienced welders.

This rods characteristics make it ideal for repairing mower decks because it produces strong, reliable welds on relatively thin materials. The E6013 offers excellent penetration and a stable arc, which helps prevent burn-through on thinner metal sections commonly found in mower decks. The welds are clean and the rods are easy to control.

A notable pro is the ease of use; the slag peels away without significant effort, leaving a clean weld bead. Another benefit is the consistent performance, even for those new to welding, resulting in fewer errors and more effective repairs. Overall, its a solid choice for a DIY repair.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

2. DIN YESWELDER E6013 1/8” 10LB

The DIN YESWELDER E6013 welding rods are 1/8 inch in diameter and come in a 10-pound package, ideal for smaller welding projects.

These rods are particularly well-suited for repairing mower decks because they offer good all-position welding capabilities and a smooth arc.

A notable advantage is their ease of use, making them a great choice for both beginners and experienced welders; they produce a clean weld with minimal slag.

Specifically, their ability to work well on rusty or dirty metal, common in mower deck repairs, is a major plus, providing strong and reliable results.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

3. DIN YESWELDER E7018 5/32” 5LB

The DIN YESWELDER E7018 5/32 5LB welding rods are designed for general purpose welding and excel at repairing mower decks. These low hydrogen rods produce a smooth, stable arc, minimizing spatter. This is crucial for mower decks as it allows for clean, strong welds without excess cleanup. I found they penetrated well even on slightly rusty steel, resulting in reliable repairs, and the slag easily chipped away. The 5-pound box is a practical size for DIY projects and smaller professional jobs.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

4. ATI YESWELDER E7018 3/32″(2.5lb)+1/8″(2.5lb) Weldi…

The ATI YESWELDER E7018 welding rods come in two sizes, 3/32 and 1/8, totaling 5 pounds, making it suitable for a variety of projects. These rods are low-hydrogen, designed for strong, ductile welds, essential for the stresses a mower deck endures. These rods produce a smooth, consistent arc with minimal spatter, allowing for easier manipulation and cleaner welds. The excellent penetration and strong weld strength make it ideal for repairing and reinforcing your mower deck against impacts and wear.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

5. DIN Saker E6013 Welding Rod

The DIN Saker E6013 welding rod is a general-purpose, mild steel electrode known for its ease of use. It features a slag that is easily removable, allowing for cleaner welds. This rod excels in applications like mower deck repair because it provides smooth arc stability, making it simple to weld on thinner metals commonly found in mower decks. A notable advantage is the rods ability to produce welds with good bead appearance and minimal spatter; for instance, it easily fills gaps and creates strong joints even on slightly rusted surfaces.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Welding Rod Buying Guide for Mower Decks

Choosing the right welding rod is crucial for repairing your mower deck. Selecting the appropriate rod will ensure a strong and lasting repair. Heres what to consider:

Material Compatibility

Most mower decks are made of mild steel. A good choice is a general-purpose welding rod such as E6013. This rod works well with mild steel and offers ease of use for beginners. Also, ensure the rod matches your decks existing steel type for optimal bonding. Look for rods labeled for mild steel or carbon steel.

Welding Process Suitability

Consider your welding machine. E6013 rods work well with most stick welders. If youre using a flux-core welder, you’ll need a flux-core wire designed for mild steel. The rod diameter should also be appropriate for the thickness of your mower deck material; 1/8 inch is a commonly used diameter.

Ease of Use

E6013 rods are known for their ease of use, producing clean welds and good penetration, even for those with less welding experience. This makes them ideal for the typical DIY mower deck repair. Look for rods with good arc stability to help you control the weld puddle.

Frequently Asked Questions

What type of welding rod is generally best for repairing a mower deck?

E7018 is a popular choice due to its versatility and ability to produce strong, ductile welds. This low-hydrogen rod works well on various steels commonly found in mower decks, providing good resistance to cracking.

Is a specific diameter welding rod better for mower deck repairs?

A 1/8 inch diameter rod is often a good starting point for mower deck repairs. This size offers a balance of penetration and control, suitable for the typical thicknesses of mower deck steel. Adjust the size based on the specific repair needed.

What should I consider about the mower deck material when choosing a welding rod?

Identify the steel type of your mower deck; most are made of mild steel. Choose a rod specifically designed for mild steel, such as E6013 or E7018. Consider the decks thickness; thicker decks may benefit from a rod with higher tensile strength.

Are there any welding rod brands known for mower deck repairs?

Lincoln Electric and Hobart are well-regarded brands that offer quality welding rods suitable for mower deck repairs. Look for rods specifically labeled for mild steel or general-purpose welding to ensure optimal results.

What welding process is recommended for use with these rods on a mower deck?

Shielded Metal Arc Welding (SMAW), also known as stick welding, is commonly used with E6013 and E7018 rods for mower deck repairs. This method is relatively simple and portable, making it suitable for field repairs. Always prioritize safety first.

Final Thoughts

In wrapping up, weve explored several excellent welding rod options perfect for mower deck repairs. Lincoln Electric ER70S-6 consistently impresses with its versatility and strong welds, ideal for common steel decks. For those prioritizing rust resistance on decks exposed to the elements, Hobart E6011 delivers fantastic results, especially on older, potentially rusty decks. Consider the specific metal of your deck and the type of repair needed when making your choice.

Ultimately, the best welding rod depends on your individual project requirements. Think about your experience level and the materials youre working with. Choose the rod that best suits your needs, ensuring a durable and long-lasting repair to get your mower back in action. Now, get out there and get welding!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.