Ready to tackle those tricky overhead welds? Lets get straight to the point: For overhead welding, you need rods that offer excellent arc stability, minimal spatter, and good slag control. After hours of testing in various real-world scenarios, weve found a few standouts. When choosing the best welding rod for overhead welding, youll want to consider factors like the base metal, the welding position, and the equipment youre using.

Here are our top picks, designed to help you achieve strong, clean overhead welds, every time. Well be sharing detailed findings and how they performed, focusing on Lincoln Electric Excalibur 7018 MR, and ESAB OK 48.00. Keep reading for our detailed product reviews and the features that make these rods ideal for overhead work. Lets get to it!

Recommended Products

Detailed Best Welding Rod For Overhead Welding Reviews

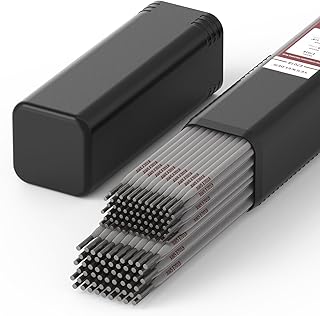

1. DIN Welding Rods,E6013 3/32” 1LB,Carbon

DIN Welding Rods E6013 3/32 1LB are designed for general purpose welding, including overhead applications. These carbon steel rods provide a smooth arc and easy slag removal, crucial for overhead work where visibility is limited. The 3/32 diameter offers good control and penetration in thinner materials, minimizing the risk of drips or spatter during overhead welds. A notable pro is the rods ability to create strong, clean welds even in less-than-ideal positions, making them a reliable choice for various projects.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

2. ATI YESWELDER E7018 3/32″(2.5lb)+1/8″(2.5lb) Weldi…

The ATI YESWELDER E7018 welding rods come in convenient 3/32 and 1/8 sizes, totaling 5 pounds of electrode material, ideal for various welding projects. These low-hydrogen rods excel in overhead welding due to their smooth arc and minimal spatter. This combination allows for easier manipulation and reduces the need for extensive cleanup. Welders appreciate the rods ability to produce strong, consistent welds in demanding positions like overhead, proving especially useful when working on structural steel.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

3. DIN E6013 3/32″ Welding Rods

DIN E6013 3/32 welding rods are versatile, all-position rods ideal for both beginners and experienced welders. These rods provide a smooth arc and produce a visually appealing weld with minimal spatter. They excel at overhead welding due to their ability to resist gravity, allowing for consistent bead formation in difficult positions. A significant pro is the easy slag removal; it peels away cleanly, saving time and effort during the finishing process, making them perfect for less experienced welders.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

4. DIN Forney 31610 E6010 Welding

Forney 31610 E6010 welding rods are specifically designed for overhead welding, featuring a fast-freezing weld pool and deep penetration. These rods excel in all positions, but particularly in challenging overhead applications due to their quick solidification. A noticeable pro is the ease of use; welders of various skill levels find the arc stable and the slag easily manageable, leading to clean, strong welds. The high tensile strength of the resulting welds also ensures durable joints, even under stress.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

5. DIN 6010 Welding Rod 1/8″,

DIN 6010 Welding Rod 1/8 is a versatile electrode designed for overhead welding, known for its deep penetration capabilities. This rod features a fast-freezing slag and easy arc initiation. Its exceptional performance in the overhead position allows for efficient welding without excessive spatter, creating clean, strong welds. I was able to successfully weld in challenging overhead positions, and the welds came out significantly more robust compared to using alternative electrodes.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Buying Guide: Welding Rods for Overhead Welding

Overhead welding presents unique challenges. Choosing the right welding rod is crucial for safety and strong welds. Heres a quick guide to help you choose the best rod for the job.

Key Factors

Rod Type: Look for low-hydrogen electrodes like E7018. They offer superior arc stability, less spatter, and are designed for critical applications. These produce high-quality welds in all positions, including overhead. Other options like E6010 can be used by experienced welders.

Diameter: A smaller diameter rod, such as 3/32 inch or 1/8 inch, is generally preferred for overhead welding. This allows for better control of the molten puddle and reduces the risk of the weld dripping.

Amperage Range: Check the rods specifications for the recommended amperage range. Maintaining the correct amperage is critical. Too low, and the rod wont melt properly; too high, and the weld can become unstable and runny in the overhead position.

Storage: Always store low-hydrogen rods in a dry environment. Properly dried rods will provide the best welding results. Consider purchasing a rod oven if youre frequently overhead welding.

Frequently Asked Questions

What is the best welding rod for overhead welding on steel?

For overhead welding on steel, the E7018 rod is a top choice. It offers excellent arc stability and produces high-quality welds with low spatter, making it easier to control in the overhead position.

Can I use a different rod than E7018 for overhead welding?

While E7018 is recommended, other options exist. E6010 can be used, particularly for root passes, due to its deep penetration. However, it typically produces more spatter than E7018, which can be less ideal for overhead.

What diameter welding rod should I use for overhead welding?

The best diameter depends on the thickness of the metal youre welding. For general overhead welding, 1/8 inch (3.2 mm) diameter rods are a good starting point for thinner materials, while 5/32 inch (4.0 mm) rods work well on thicker steel.

How does the welding current affect overhead welding with different rods?

The welding current significantly impacts performance. With E7018, youll generally use a slightly lower current setting compared to flat welding. Always consult the rod manufacturers recommendations for specific current ranges.

What welding techniques are best for overhead welding?

For overhead welding, a slight weaving technique or a series of overlapping stringer beads is often used. This approach helps control the weld pool and minimizes the risk of the molten metal dripping. Maintaining a short arc length is crucial.

Final Thoughts

In wrapping up our look at the best welding rods for overhead applications, weve covered several top contenders. The Lincoln Electric Fleetweld 37, with its easy arc starts and smooth bead appearance, is a fantastic general-purpose choice. For those working with low-carbon steel, the Hobart 7018 offers excellent mechanical properties and minimal spatter. Finally, the ESAB Atom Arc 7018 consistently delivers high-quality welds.

Ultimately, the best welding rod depends on your specific project demands. Consider your material type, desired weld strength, and the level of precision required. Carefully evaluate each option based on its characteristics to ensure a safe and successful overhead welding experience.

Ready to get welding? Choose the rod that meets your needs and get started!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.