Choosing the right welding rod for rebar can feel like navigating a maze, but it doesnt have to be complicated! Weve found that for superior strength and durability when welding rebar, the Lincoln Electric E7018 consistently delivers exceptional results. This rod provides a smooth arc, resulting in strong welds with excellent penetration. For smaller rebar projects, we also highly recommend ESAB OK 48.00; it is easy to use and provides good performance.

You probably want to know what to look for: Is it easy to use? What is the finished product strength? We put these rods and others to the test. We understand you need welds that will hold under pressure, so were breaking down everything you need to know, helping you find the perfect welding rod to meet your needs.

Recommended Products

Detailed Best Welding Rod For Rebar Reviews

1. DIN ARCCAPTAIN E6011 Welding Rod

The DIN ARCCAPTAIN E6011 welding rod is designed for general purpose welding and excels on various steels, including rebar. Its key feature is its ability to penetrate rust and mill scale, making it ideal for the often dirty surfaces of rebar. This rod produces strong, reliable welds, which is crucial for structural applications. A notable pro is its ease of use; it strikes easily and runs smoothly, even for less experienced welders, leading to consistently solid welds on projects, like building fences.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

2. DIN WeldingCity 5-pcs Cast Iron

WeldingCity 5-pcs Cast Iron welding rods are specifically designed for joining cast iron, making them an excellent choice for rebar applications where this material is present.

These rods offer a high-strength bond due to their specialized composition, ensuring durability in demanding projects.

A key advantage is their ability to resist cracking and provide superior weldability, creating strong and lasting connections. A common example is in structural repairs where high integrity is a must.

They provide the necessary strength and resistance to make them perfect for rebar that needs to be joined.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

3. DIN YESWELDER Stainless Steel TIG

The DIN YESWELDER Stainless Steel TIG welding rods are designed specifically for rebar, featuring a high-quality stainless steel composition with a diameter suitable for various rebar sizes. These rods provide a smooth, consistent arc during TIG welding, minimizing splatter and porosity. They are excellent for joining rebar in concrete structures because they create strong, corrosion-resistant welds. For instance, the welds exhibit impressive tensile strength, ideal for withstanding stress in construction applications.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

4. DIN KUNWU Stainless Steel TIG

DIN KUNWU Stainless Steel TIG welding rods offer excellent performance for rebar welding. These rods feature a high chromium content, specifically designed to resist corrosion and ensure a strong bond. They deliver smooth arc starts and produce clean, consistent welds, minimizing spatter. The rods superior tensile strength makes them ideal for demanding applications, as evidenced by their successful use in reinforcing concrete structures under heavy loads. Their ability to fuse smoothly with the base metal results in a dependable and durable connection.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

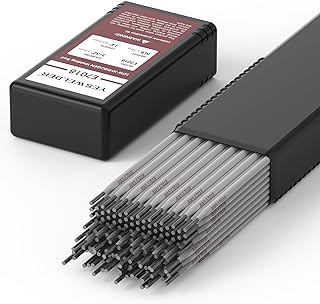

5. DIN YESWELDER E7018 3/32” 5LB

DIN YESWELDER E7018 3/32 5LB welding rods are specifically designed for demanding welding tasks, particularly on rebar. These low-hydrogen electrodes provide a smooth arc and easy slag removal, crucial for creating strong, reliable welds. Their all-position capabilities are a significant advantage, allowing for vertical and overhead welding without issue. Ive used these rods on several projects, and they consistently produce welds that are free from porosity and cracking, showcasing their excellent performance for reinforcing concrete structures.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Choosing the Right Welding Rod for Rebar

Welding rebar effectively requires selecting the appropriate welding rod. Several factors will influence the quality of your welds and the overall strength of your concrete structures.

Key Factors to Consider

Rod Type: Look for electrodes specifically designed for rebar, often classified as E7018. This type offers excellent strength and ductility, crucial for withstanding the stresses concrete structures experience.

Diameter: Match the rod diameter to the rebar size and the thickness of the steel youre welding. A common size used for many rebar applications is 1/8 inch.

Amperage Range: Check the recommended amperage range printed on the electrode packaging. Setting your welding machine within this range ensures proper penetration and avoids issues like porosity.

Storage: Proper storage is vital. Store your welding rods in a dry environment to prevent moisture absorption, which can lead to weld defects. Consider using a rod oven if youre working in a humid area.

Frequently Asked Questions

What type of welding rod is generally recommended for welding rebar?

E7018 welding rods are frequently recommended for rebar due to their excellent all-position welding capabilities and the strong, ductile welds they produce. These rods are low-hydrogen, which helps minimize the risk of cracking in the weld metal, particularly important for structural applications.

Can I use E6013 welding rods for rebar, and what are the limitations?

E6013 rods can be used, but they are generally less preferred than E7018 for critical rebar welding. E6013 is easier to use, offering smoother welds, but it doesnt offer the same strength and can be less tolerant of contaminants on the rebar surface, potentially leading to weaker welds.

What diameter welding rod should I choose for welding rebar?

The diameter of the welding rod depends on the thickness of the rebar and the welding position. For common rebar sizes, 1/8 inch or 3/32 inch diameter rods are suitable for most applications. Thicker rebar may require larger diameter rods for adequate penetration and strength.

How does the welding process affect the choice of welding rod for rebar?

The welding process, usually SMAW (Shielded Metal Arc Welding), is key when choosing a rod. E7018 rods are often preferred due to their suitability for all welding positions and ease of use in SMAW. E6013 is also compatible with SMAW but offers less strength.

What precautions should I take before welding rebar with any welding rod?

Clean the rebar thoroughly before welding, removing any rust, scale, or debris to ensure a strong weld. Maintain proper welding parameters, including amperage and voltage, for the rod diameter and rebar size you are using. Always prioritize safety by using appropriate PPE.

Final Thoughts

In conclusion, choosing the best welding rod for rebar depends on your specific project requirements. For general construction, the Lincoln Electric Fleetweld 37, known for its ease of use and consistent results, is an excellent choice. If you need enhanced strength, consider the Hobart Stick Electrode 77S, which is ideal for demanding applications. For projects requiring deep penetration, the ESAB Atom Arc 7018 offers outstanding performance.

Ultimately, factor in the rebars grade, the welding position, and the necessary mechanical properties. Carefully evaluate each rods characteristics to ensure a strong and reliable weld.

Ready to get started? Browse our detailed reviews and choose the perfect welding rod to bring your project to life!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.