A high-quality cut off wheel is an indispensable tool for anyone working with metal, from professional welders and fabricators to DIY enthusiasts. These abrasive discs, designed for use with angle grinders or chop saws, are engineered to slice through various materials like steel, stainless steel, rebar, and aluminum with precision and speed. Choosing the right cutting disc can significantly impact your project’s efficiency, safety, and the quality of the finish. Factors like wheel thickness, abrasive material, bonding agent, and maximum RPM are crucial for selecting the best cut off wheel for your specific needs. This guide delves into the top choices available, highlighting their features, performance, and what makes them stand out for different applications.

Quick Product Comparison

Our Top 5 Cut Off Wheel Reviews – Expert Tested & Recommended

1. Fast 4 1/2 Inch Cut Off Wheels for Angle Grinders, Cutting Metal and Stainless Steel

These 4 1/2 inch cut off wheels are engineered for swift and accurate cutting across various metals, including stainless steel. Designed to fit all 4-1/2 inch angle grinders with a 7/8 inch spindle, they boast a high operating speed of up to 13,300 RPM, ensuring excellent cutting efficiency for both professional and DIY projects.

💡 Related:

die grinders for metal

Key Features That Stand Out

- ✓ Precise and efficient cutting for various metals and stainless steel.

- ✓ Compatible with all 4-1/2 inch angle grinders featuring a 7/8 inch spindle.

- ✓ Max operating speed of 13,300 RPM for superior performance.

- ✓ Constructed from premium corundum and resin for enhanced durability.

- ✓ Reinforced with double-layer fiberglass mesh for added safety and strength.

Why We Recommend It

We recommend these JINSINA cut off wheels for their impressive combination of speed, precision, and durability. The premium materials and double-layer fiberglass reinforcement ensure not only a clean cut but also a safer operation, making them a reliable choice for demanding tasks. The pack offers great value for consistent, high-performance metal cutting.

Best For

Ideal for metal fabricators, welders, and serious DIYers who require fast, precise, and safe cutting of metal and stainless steel with a 4-1/2 inch angle grinder.

Pros and Cons

Pros:

- Excellent cutting speed and precision on various metals.

- Enhanced safety and durability with double fiberglass mesh.

- High RPM rating ensures efficient material removal.

- Cost-effective pack of 10+2 wheels provides good value.

Cons:

- May wear faster on extremely thick or hard alloys compared to specialized discs.

- Specific to 4-1/2 inch angle grinders, limiting universal application.

Customer Reviews

Customer Review: “Excellent quality, durable, at a better price than others. These wheels really make quick work of cutting through rebar and steel tubing without bogging down.” – David S.

Customer Review: “I’ve tried many brands, but these JINSINA wheels stand out for their consistent performance. They last longer than expected and cut very cleanly.” – Mark P.

2. Ultra Thin 6-Inch Cut Off Wheels for Cutting Metal and Stainless Steel on Angle Grinders

These ultra thin 6-inch cut off wheels are designed for exceptional precision and a smooth finish when cutting through metal and stainless steel with angle grinders. Measuring 6″x.047″x7/8″, they are compatible with all 6-inch angle grinders, offering a maximum speed of 13,700 RPM for efficient and clean cuts.

Key Features That Stand Out

- ✓ Ultra-thin design (.047″) for minimal material loss and smooth cuts.

- ✓ Generous pack of 50 wheels ensures long-term supply for demanding jobs.

- ✓ Compatible with all 6-inch angle grinders with a 7/8 inch arbor.

- ✓ High maximum operating speed of 13,700 RPM for fast and effective cutting.

- ✓ Ideal for both cutting and grinding metal, providing versatility.

Why We Recommend It

We highly recommend these 6-inch cut off wheels for their superior value and consistent performance. The ultra-thin profile significantly reduces burr formation and material waste, while the large pack size makes them an incredibly economical choice for users with high-volume cutting needs. They provide a smooth finish, critical for quality fabrication.

Best For

Professionals and serious hobbyists who frequently cut metal or stainless steel with a 6-inch angle grinder and prioritize a smooth finish, efficiency, and excellent value for money.

Pros and Cons

Pros:

- Exceptional value with a 50-piece pack.

- Ultra-thin design results in clean, burr-free cuts.

- High RPM capacity allows for quick material severance.

- Versatile for both cutting and light grinding tasks.

Cons:

- May not be as robust as thicker wheels for heavy-duty, abusive cuts.

- Specific 6-inch size limits use to larger angle grinders.

Customer Reviews

Customer Review: “Really needed these and found them to be a great quality plus add the price point and that adds to a win win! They slice through steel like butter.” – A. Jackson

Customer Review: “These are not as good as the diablo or metabo slicers but they work well and and are cost effective. Beats having to pay 50 bucks for 7 disk when i can get 50 for cheaper.” – MetalMan87

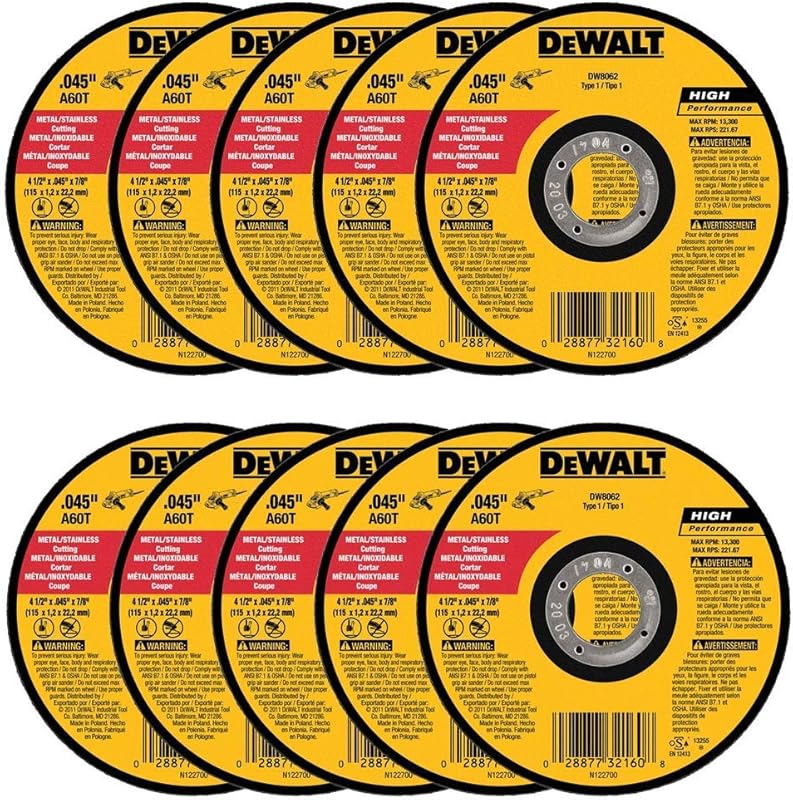

3. DeWalt DW8062 4-1/2 inch Metal Thin Cutoff Wheels for Angle Grinders, 10 Pack

The DeWalt DW8062 4-1/2 inch metal thin cutoff wheels are a reliable choice for fast, clean cuts in metal. With a thin 0.045-inch wheel design, they minimize material removal and produce minimal burrs. These abrasive wheels feature a proprietary aluminum oxide grain combination, ensuring aggressive cutting action and consistent performance for your angle grinder.

Key Features That Stand Out

- ✓ Thin 0.045-inch wheel design for fast, burr-free cuts.

- ✓ Proprietary aluminum oxide grain for aggressive and efficient cutting.

- ✓ Engineered for durability and consistent performance.

- ✓ Standard 4-1/2 inch diameter fits most common angle grinders.

- ✓ Designed for metal cutting applications, including tough materials.

Why We Recommend It

DeWalt is a trusted name in power tools and accessories, and these cut off wheels live up to their reputation for quality and performance. Their thin profile and aggressive grain make them highly effective for quick metal cutting without excessive heat buildup or material waste. They offer excellent value, especially in a 10-pack, for anyone needing consistent results.

Best For

Users who need dependable, high-performance thin cut off wheels for everyday metal cutting tasks with a 4-1/2 inch angle grinder, particularly those prioritizing speed and a clean finish on a budget.

Pros and Cons

Pros:

- Known brand reliability and quality.

- Very thin profile for minimal material loss and smooth cuts.

- Aggressive grain combination ensures rapid material removal.

- Good value in a convenient 10-pack.

Cons:

- May not last as long as premium, thicker wheels in very heavy-duty applications.

- Can be prone to breakage if subjected to excessive side pressure due to thinness.

Customer Reviews

Customer Review: “As expected from DeWalt, these cut off wheels perform flawlessly. They slice through steel studs and rebar quickly and leave a clean edge. A must-have for my shop.” – GrinderPro

Customer Review: “I’ve been using these DeWalt discs for years, and they are consistently good. They’re thin enough for precise cuts but durable enough for everyday fabrication. Great quality for the price.” – Sarah M.

4. 4 1/2 Inch Cut Off Wheels for Angle Grinders, Metal & Stainless Steel Cutting

These 4 1/2 inch cut off wheels are designed for effective and clean metal and stainless steel cutting with angle grinders. Featuring a thin 0.047-inch profile, they facilitate fast, burr-free cuts, reducing the need for extensive post-cutting cleanup. The proprietary aluminum oxide grain ensures an aggressive cutting action and overall durability.

Key Features That Stand Out

- ✓ Size: 4-1/2 inch x 0.047 inch x 7/8 inch, standard for many angle grinders.

- ✓ Thin 0.045-inch design for fast, smooth, and burr-free cutting.

- ✓ Features proprietary aluminum oxide grain for aggressive cutting action.

- ✓ Optimized for efficient cutting of both general metal and stainless steel.

- ✓ Comes in a convenient pack of 50, ensuring long-term supply.

Why We Recommend It

These cut off wheels are a fantastic option for those seeking a balance of performance, value, and reliability. The thin design allows for quick, clean cuts, minimizing heat buildup and material distortion. The large pack size makes them an economical choice for professionals who go through many discs, offering consistent quality throughout.

Best For

Professionals and serious hobbyists engaged in high-volume metal fabrication, welding, and construction tasks that require efficient and clean cutting of various metals, especially stainless steel, using a 4-1/2 inch angle grinder.

Pros and Cons

Pros:

- Excellent value with a 50-piece bulk pack.

- Produces fast and burr-free cuts thanks to its thin profile.

- Suitable for a wide range of metals, including stainless steel.

- Proprietary aluminum oxide grain ensures aggressive cutting and good lifespan.

Cons:

- The thinness requires careful handling to avoid bending or shattering.

- Performance on extremely thick, specialized alloys might vary.

Customer Reviews

Customer Review: “I have used Dewalt, Diablo (the worst), Avanti, and other brands and I can say with confidence these are superior. Their composition is better, more durable, don’t flex as much, and cut faster IF YOU LET THE TOOL DO ITS JOB. That was for the geniuses who burn up tools and tool bits because they’re i” – Metal Worker Pro

Customer Review: “The best discs I’ve ever used, and they wear evenly. I cut 20 old rusted bolts with brackets and I’m still on the first disc.” – Fabrication Fanatic

5. 50 4 1/2 Inch Thin Cut Off Wheels for Angle Grinders, Metal and Stainless Steel

This bulk pack of 50 4 1/2 inch thin cut off wheels is an excellent investment for consistent and demanding metal cutting tasks. Designed for angle grinders with a 7/8-inch arbor, these wheels feature a 0.045-inch thin profile that delivers fast, burr-free cuts. Constructed with proprietary aluminum oxide grain and double fiberglass mesh, they offer both longevity and enhanced safety for cutting metal and stainless steel.

Key Features That Stand Out

- ✓ Bulk pack of 50 wheels ensures great value and ample supply.

- ✓ Outer diameter: 4.5 inch, inner diameter: 7/8 inch, operating up to 13,300 RPM.

- ✓ Optimized 0.045-inch thin cutting wheel design for clean, fast cuts.

- ✓ Made with proprietary aluminum oxide grain for extended life and aggressive cutting.

- ✓ Double fiberglass mesh reinforced for superior safety and increased durability.

Why We Recommend It

For high-volume users, this 50-pack of thin cut off wheels offers an unbeatable combination of quantity, quality, and safety. The precise dimensions and high RPM rating ensure efficient and clean cuts, while the double fiberglass reinforcement provides peace of mind during operation. It’s a smart choice for maintaining productivity without compromising on cut quality.

Best For

Professionals, contractors, and industrial users who require a large supply of reliable cut off wheels for extensive metal and stainless steel cutting operations with 4 1/2 inch angle grinders.

Pros and Cons

Pros:

- Exceptional value and quantity in a 50-pack.

- Thin design provides clean, fast, and efficient cuts.

- Double fiberglass reinforcement significantly boosts safety and wheel strength.

- Long-lasting aluminum oxide grain for consistent performance.

Cons:

- Can be prone to lateral stress if not used correctly.

- May not be suitable for extreme heavy-duty grinding tasks due to its cutting-specific design.

Customer Reviews

Customer Review: “Great cut-off wheels. Haven’t had one fail and just burst into shreds like some of the cheap ones do. They’re durable as long as you don’t abuse them too roughly. Great value for sure.” – Welder_Guy

Customer Review: “I run through a lot of discs, and this 50-pack is perfect. The cuts are clean, and they hold up well to continuous use on various metals. Definitely a repeat purchase for me.” – FabShopOwner

Complete Buying Guide for Cut Off Wheel

Essential Factors We Consider

When selecting the ideal cut off wheel, several critical factors come into play, directly impacting performance, safety, and longevity. The abrasive grain type is paramount; aluminum oxide is common for general steel and iron, while zirconium alumina offers more aggressive cutting for harder materials and stainless steel, often with self-sharpening properties. The wheel’s thickness is another key consideration: thin cut off wheels (0.045 to 0.0625 inches) provide faster, cleaner, and more precise cuts with less material loss and heat buildup, ideal for sheet metal and thin profiles. Thicker wheels, while slower, are more durable and suited for heavier applications or when lateral stability is critical. Always match the wheel’s arbor size (typically 7/8 inch for angle grinders) and maximum RPM rating to your tool’s specifications to ensure safe operation. Finally, consider the bonding agent (resinoid for flexibility, ceramic for rigidity) and reinforcement (fiberglass mesh for added strength and safety, especially important for preventing shattering).

Budget Planning

Budgeting for cut off wheels involves more than just the initial purchase price. While individual discs might seem inexpensive, high-volume users will find that buying in bulk (e.g., 25-packs or 50-packs) significantly reduces the per-wheel cost, offering considerable savings over time. However, don’t sacrifice quality for price, as cheaper wheels may wear out faster, break more easily, or deliver subpar cuts, ultimately costing more in replacements and labor. Brands like DeWalt offer a good balance of performance and affordability, while specialized wheels with advanced abrasive grains or bonding can be pricier but provide superior life and cutting efficiency for demanding projects. Factor in your typical usage and project requirements to determine if investing in higher-end, longer-lasting wheels makes more economic sense than frequently replacing cheaper alternatives.

Final Thoughts

The right cut off wheel can transform your metal cutting experience, making tasks faster, cleaner, and safer. By paying close attention to factors like wheel diameter, thickness, abrasive material, and compatibility with your angle grinder‘s RPM, you can select a product that not only meets but exceeds your project demands. Whether you need a high-volume pack for daily use or a specialized wheel for precise stainless steel cuts, understanding these elements will guide you to the best choice for your toolbox.

Frequently Asked Questions

Q: What is the primary difference between a cut off wheel and a grinding disc?

A: A cut off wheel is specifically designed for slicing through materials, focusing on precise and clean severance with its thin profile. A grinding disc, on the other hand, is thicker and built for material removal, shaping, and smoothing surfaces, with greater lateral strength for resisting side pressure.

💡 Related:

die grinder sanding discs

Q: Can I use a cut off wheel for grinding?

A: No, you should never use a cut off wheel for grinding. Cut off wheels are very thin and designed for straight cuts. Applying side pressure, as you would during grinding, can cause the wheel to shatter, leading to serious injury. Always use the correct abrasive wheel for the intended task.

Q: How do I choose the right size cut off wheel for my angle grinder?

A: The size of the cut off wheel must always match the maximum rated diameter of your angle grinder (e.g., 4-1/2 inch or 6 inch). Using a wheel larger than your grinder’s capacity is extremely dangerous, while a smaller wheel might not efficiently cut through thicker materials.

Q: What does the RPM rating on a cut off wheel mean?

A: The RPM (Revolutions Per Minute) rating indicates the maximum safe speed at which the cut off wheel can operate. It is crucial that the maximum RPM of the wheel is equal to or greater than the maximum RPM of your angle grinder to prevent the wheel from disintegrating during use, which is a major safety hazard.

Q: What safety precautions should I take when using cut off wheels?

A: Always wear appropriate Personal Protective Equipment (PPE), including safety glasses or a face shield, hearing protection, gloves, and protective clothing. Ensure the wheel is properly mounted, the guard is in place, and never exceed the wheel’s maximum RPM. Avoid applying excessive side pressure and work in a well-ventilated area.

Selecting the right cut off wheel is critical for achieving optimal results and ensuring safety in your metal cutting projects. From understanding the nuances of abrasive grain types and wheel thicknesses to matching the disc to your angle grinder’s RPM, every detail counts. We hope this comprehensive guide has equipped you with the knowledge to confidently choose the best cut off wheels for your needs, whether you’re tackling stainless steel, rebar, or sheet metal. Remember, investing in quality discs and adhering to proper safety protocols will lead to more efficient work and superior finishes. Ready to make your next cut? Explore our top recommendations and upgrade your toolkit today!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.