Pipeline welding is the process of joining sections of pipe together using welding techniques. It involves welding pipes to create a continuous pipeline for various applications, such as transportation of fluids or gases.

Pipeline welding works by heating the edges of the pipes and melting them together to form a strong and durable joint. This process requires skilled welders, specialized equipment, and adherence to safety standards to ensure the quality and integrity of the pipeline.

With the demand for pipelines increasing globally, pipeline welding plays a crucial role in ensuring the efficiency and reliability of the infrastructure that supports industries like oil and gas, water supply, and more.

Photo by fabtechexpo

About Pipeline Welding

Pipeline welding is a specialized process used to join sections of pipe together to create a continuous system. It involves using specialized welding techniques to ensure the strength and integrity of the pipeline. Welders work with a variety of materials and must follow strict guidelines to meet safety and quality standards.

Welding In Pipeline Construction

In pipeline construction, welding plays a crucial role in joining sections of pipe together to create a continuous and reliable pipeline network. Welding is the primary method used to connect pipes and ensure their integrity and strength. It is a specialized technique that requires skilled professionals who are trained in various welding processes.

Types Of Pipelines

There are several types of pipelines used for different purposes:

- Oil and Gas Pipelines: These pipelines transport crude oil, natural gas, and refined petroleum products over long distances.

- Water Pipelines: Water pipelines are used to supply clean drinking water, irrigation water, and wastewater disposal systems.

- Chemical Pipelines: These pipelines transport various chemicals, such as acids and solvents, safely and efficiently.

- Slurry Pipelines: Slurry pipelines are used to transport mixtures of water and solids, commonly used in mining operations.

Each type of pipeline requires specific welding techniques and materials to ensure the pipeline’s durability and safety.

Welding in pipeline construction involves a series of steps to ensure a strong and reliable connection. The process begins with preparing the pipe ends by cleaning and beveling them to create a suitable joint. Next, the pipes are aligned and clamped together to maintain precise positioning during welding.

The actual welding process involves heating the pipe ends and applying filler material, typically in the form of a welding electrode, to create a molten pool. The molten pool solidifies to form a strong bond between the pipes. Welders use various welding techniques, such as Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), or Submerged Arc Welding (SAW), depending on the specific requirements of the pipeline.

After the welding is complete, the weld undergoes inspection to ensure its quality. Various non-destructive testing methods, such as X-ray, ultrasonic testing, or magnetic particle inspection, are employed to detect any defects or imperfections in the weld. If the weld passes inspection, it is considered acceptable and ready for further pipeline construction.

Basics Of Welding Technology

Welding plays a crucial role in the construction and maintenance of pipelines. It involves joining metal components together using heat and pressure, creating a durable and secure bond.

Understanding the welding processes and techniques as well as the equipment used in pipeline welding is essential for ensuring the integrity and safety of the pipelines.

Welding Processes And Techniques

Various welding processes and techniques are employed in pipeline welding, including:

- Shielded Metal Arc Welding (SMAW)

- Gas Tungsten Arc Welding (GTAW)

- Gas Metal Arc Welding (GMAW)

- Flux-Cored Arc Welding (FCAW)

Equipment Used In Pipeline Welding

The equipment used in pipeline welding includes:

- Welding machine

- Welding electrodes

- Protective gear (helmets, gloves, etc.)

- Clamps and fixtures

Image by thefabricator

Materials Used In Pipeline Construction

When it comes to pipeline welding, choosing the right materials is crucial for ensuring the durability and integrity of the pipelines. The materials used in pipeline construction play a significant role in determining the overall strength and longevity of the pipelines. In this section, we will explore the importance of choosing the right metals and discuss the properties of pipeline materials.

Choosing The Right Metals

When selecting metals for pipeline construction, several factors need to be considered. These include the specific requirements of the project, such as the type of fluid or gas being transported, the operating conditions, and the environmental factors. Some commonly used metals for pipeline construction include:

Carbon Steel: Carbon steel is widely used in pipeline construction due to its excellent strength and durability. It is relatively inexpensive and can withstand high-pressure conditions.

Stainless Steel: Stainless steel is known for its corrosion resistance properties, making it suitable for pipelines that transport corrosive fluids or operate in harsh environments.

Alloy Steel: Alloy steel is often used in pipelines that require enhanced strength, such as high-pressure gas pipelines. It contains additional alloying elements to improve its mechanical properties.

Properties Of Pipeline Materials

The properties of pipeline materials play a crucial role in determining their suitability for specific applications. Some important properties to consider include:

Tensile Strength

The tensile strength of a material refers to its ability to withstand tension or pulling forces without breaking. High tensile strength is desirable for pipelines to ensure they can withstand the internal pressure and external forces.

Corrosion Resistance

Corrosion resistance is particularly important for pipelines that transport fluids or gases that may cause corrosion. Materials with high corrosion resistance, such as stainless steel, help prevent the degradation of pipelines over time.

Weldability

The weldability of a material refers to how easily it can be welded. It is essential to choose materials that can be effectively welded to ensure strong and reliable pipeline joints.

Temperature Resistance

Pipeline materials must be able to withstand the temperature conditions they will be exposed to during operation. Materials with good temperature resistance can prevent deformation or failure under extreme temperatures.

Fracture Toughness

Fracture toughness measures a material’s ability to resist the growth of cracks. High fracture toughness is crucial for preventing catastrophic failures in pipelines.

By considering these properties and selecting the appropriate metals, pipeline construction can ensure the safe and efficient transportation of fluids and gases over long distances.

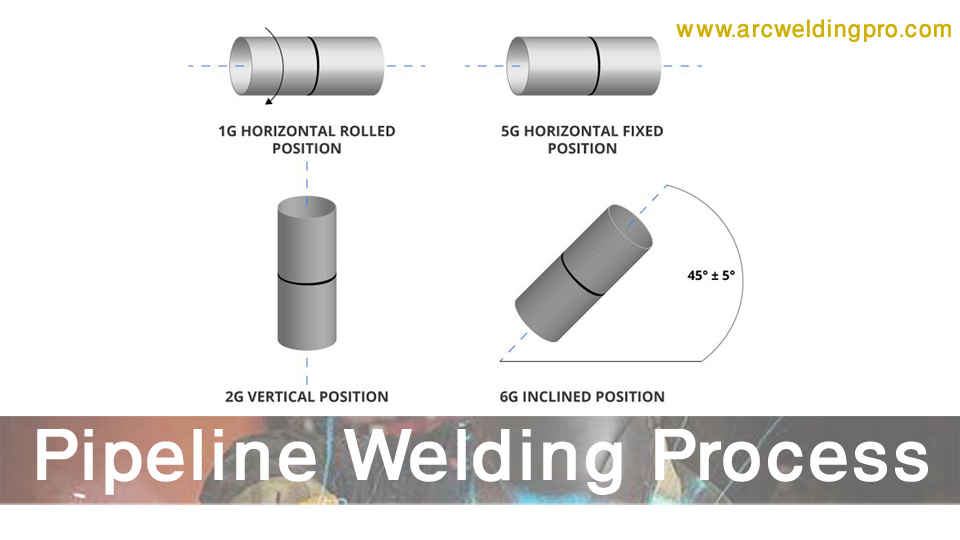

Steps in the Pipeline Welding Process

Pipeline welding involves several key steps, starting with preparation of the pipe ends and welding bevels. Next, the pipes are aligned and tacked into place before the root pass welding begins. Once the root pass is complete, subsequent fill and cap passes are applied to complete the weld.

Image by twi-global

Pipe Preparation

- Before welding, pipes are inspected and cleaned to remove dirt and rust.

- Ends are beveled for a proper fit, ensuring a strong weld joint.

Alignment And Tack Welding

- Pipes are aligned using clamps or jacks to ensure a straight position.

- Tack welding secures the pipes in place before the main welding operation.

Main Welding Operations

- The main welding process involves joining the pipes using techniques like arc welding.

- Welders carefully fuse the pipes together to create a seamless connection.

Welding Methods for Pipelines

Pipeline welding utilizes various methods like shielded metal arc welding to join pipes together, ensuring secure connections for efficient transportation of liquids or gases. The process involves skilled welders using specialized equipment to create strong, durable welds that meet strict industry standards.

Manual Welding Techniques

Pipeline welding involves various methods, with manual techniques being one of the primary approaches. This method requires skilled welders to use welding equipment to join pipes together. The welders carefully control the welding process to ensure strong and durable connections. Manual welding is suitable for smaller pipelines and areas that are difficult to access with automated machinery.

Automated And Semi-automated Welding

For larger pipelines and projects, automated and semi-automated welding techniques are utilized. These methods involve the use of specialized machinery that can weld pipes quickly and efficiently. Automated systems are programmed to follow precise welding patterns, ensuring consistent quality throughout the pipeline. Semi-automated welding combines the precision of automation with manual control for more complex welds.

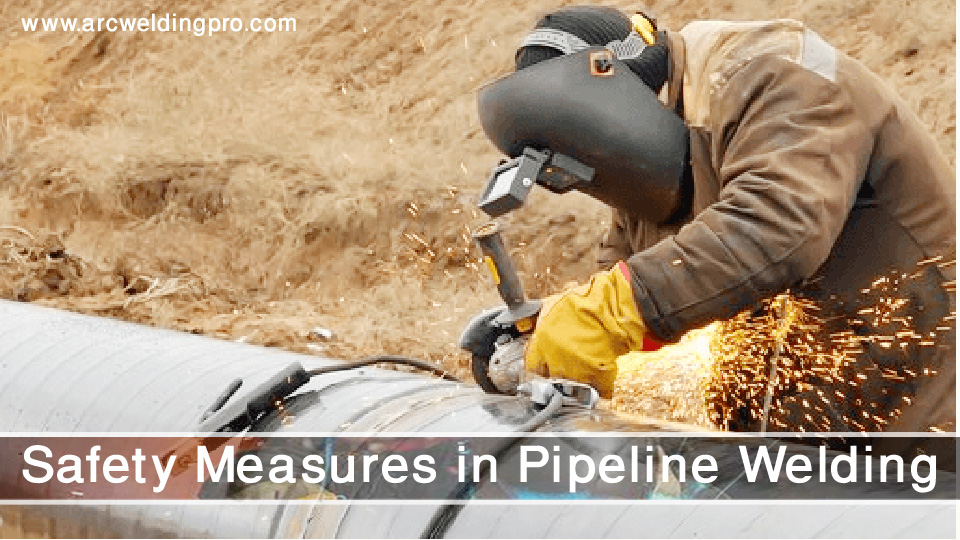

Safety Measures in Pipeline Welding

When it comes to pipeline welding, safety measures are paramount to protect workers and ensure the integrity of the infrastructure. Understanding and implementing proper safety protocols is essential to prevent accidents and injuries during the welding process.

Personal Protective Equipment

Welders involved in pipeline welding must utilize appropriate personal protective equipment (PPE) to safeguard themselves from potential hazards. This includes wearing protective clothing, gloves, helmets, and safety glasses to shield against sparks, heat, and debris. Respiratory protection is also crucial due to the fumes and gases generated during the welding process.

Hazard Awareness And Prevention

Being aware of potential hazards and taking proactive measures to prevent accidents is vital in pipeline welding. Regular inspection of the work area for any potential dangers such as flammable materials, gas leaks, or unstable ground is essential. Adhering to safety guidelines to avoid fire hazards and implementing proper ventilation systems to reduce exposure to harmful fumes are imperative for a safe working environment.

Image by pces.uk

Quality Control and Inspection

Quality control and inspection are crucial aspects of pipeline welding to ensure the integrity and safety of the welded joints. By adhering to strict quality control measures and conducting thorough inspections, potential defects and weaknesses in the welds can be identified and rectified, ultimately contributing to the overall reliability of the pipeline.

Non-destructive Testing Methods

Non-destructive testing (NDT) methods play a vital role in evaluating the quality of welds without causing any damage to the welded components. Techniques such as ultrasonic testing, radiographic testing, and magnetic particle inspection are commonly employed to detect internal and surface defects in the welded joints. These methods enable inspectors to identify any imperfections that may compromise the structural integrity of the welds, allowing for timely remediation.

Ensuring Weld Integrity

Ensuring the integrity of pipeline welds involves meticulous inspection procedures to validate the strength and durability of the welded joints. Utilizing visual inspection, dye penetrant testing, and radiographic examination, inspectors can verify the soundness of the welds and ensure they meet the specified quality standards. By scrutinizing the welds for any discontinuities or irregularities, the overall integrity of the pipeline can be safeguarded.

Challenges and Solutions in Pipeline Welding

Pipeline welding involves joining sections of pipes to create a continuous pipeline. Challenges in pipeline welding include ensuring proper alignment and achieving high-quality welds. Solutions include using advanced welding techniques and equipment, as well as skilled welders who follow stringent safety and quality standards.

Environmental Concerns

Pipeline welding is a critical process that helps to ensure the safety and reliability of oil and gas pipelines. However, it’s not without its challenges. One of the biggest concerns is the impact that pipeline welding can have on the environment. Welding can produce harmful emissions, including greenhouse gases and other pollutants that can harm the air and water quality.

Additionally, pipeline construction can lead to habitat destruction and other environmental damage. To mitigate these concerns, pipeline welders must take steps to reduce their environmental impact. This can include using low-emission welding processes, minimizing waste, and implementing other sustainable practices.

Technological Advancements

Pipeline welding has come a long way in recent years thanks to advancements in technology. Today, pipeline welders have access to a wide range of tools and techniques that can help them work more efficiently and effectively. For example, some pipeline welders use automated welding systems that can improve the accuracy and consistency of welds. Additionally, new materials and coatings can help to protect pipelines from corrosion and other types of damage.

By staying up-to-date with the latest technological advancements, pipeline welders can ensure that they are providing the best possible service to their clients while also minimizing their environmental impact. When it comes to pipeline welding, there are a number of challenges that must be addressed. Environmental concerns and technological advancements are just two examples.

By taking a proactive approach and implementing sustainable practices and cutting-edge technology, pipeline welders can overcome these challenges and provide safe, reliable pipelines for years to come. Whether you’re a pipeline welder or a client in need of pipeline welding services, it’s important to work with a team that is committed to delivering high-quality work while also protecting the environment.

Image by afuncan

Future Of Pipeline Welding

Pipeline welding has come a long way since its inception and has made significant strides in terms of technology and innovation. With the constant need for energy and transportation of resources, pipeline welding is a critical process that ensures the safe and efficient transfer of oil, gas, and water across vast distances.

The future of pipeline welding is constantly evolving with new trends and advancements in technology that are making the process even more efficient and cost-effective.

Innovations In Welding Technology

Recent advancements in welding technology have paved the way for more efficient and safer pipeline welding practices. With the use of automated welding machines, robots, and other cutting-edge equipment, the welding process has become more accurate and precise, reducing the possibility of errors and defects. These machines also speed up the welding process, reducing the time and cost required to complete a project.

The use of advanced welding techniques such as friction stir welding and laser welding has significantly improved the quality of welds, making them stronger and more durable.

Trends In Pipeline Construction

With the need for more sustainable and environmentally friendly practices, pipeline construction is also evolving to meet these demands. The use of alternative materials such as composite pipes and biodegradable coatings is becoming more common. These materials are not only eco-friendly but also provide greater durability and resistance to corrosion.

Additionally, pipeline construction is moving towards more modular and prefabricated systems that can be easily assembled on site, reducing the time and cost required for construction.

| Trends in Pipeline Welding | Description |

|---|---|

| Increased use of automation | Automated welding machines and robots are becoming more common, reducing errors and speeding up the welding process. |

| Advanced welding techniques | Techniques such as friction stir welding and laser welding are improving the quality and strength of welds. |

| Alternative materials | Composite pipes and biodegradable coatings are becoming more popular due to their durability and eco-friendliness. |

| Modular and prefabricated systems | Construction is moving towards more modular and prefabricated systems, reducing time and cost required for assembly on site. |

The future of pipeline welding looks promising with the use of advanced technology and sustainable practices that improve the safety, efficiency, and durability of pipelines. As the demand for energy and resources continues to grow, pipeline welding will play an increasingly important role in ensuring their safe and efficient transport.

Conclusion

Pipeline welding is a crucial process in the construction and maintenance of pipelines. It involves joining two or more metal pipes using heat and pressure to create a strong and durable bond. With the help of skilled welders and advanced technology, pipeline welding has become safer and more efficient over the years.

It still requires careful planning, execution, and monitoring to ensure the quality and integrity of the pipeline. As such, it is important to hire experienced and certified pipeline welders to ensure the success of any pipeline project.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.