An abrasive cut off wheel is an indispensable tool in metalworking, construction, and DIY projects, designed to efficiently slice through various materials like metal, steel, rebar, and more. These thin, bonded abrasive discs, typically used with angle grinders or chop saws, deliver quick and clean cuts, making them essential for fabrication, repair, and demolition tasks. Choosing the right cut off wheel can significantly impact your productivity, cut quality, and safety, which is why we’ve compiled a list of the top performers in the market.

Quick Product Comparison

Our Top 5 Abrasive Cut Off Wheel Reviews – Expert Tested & Recommended

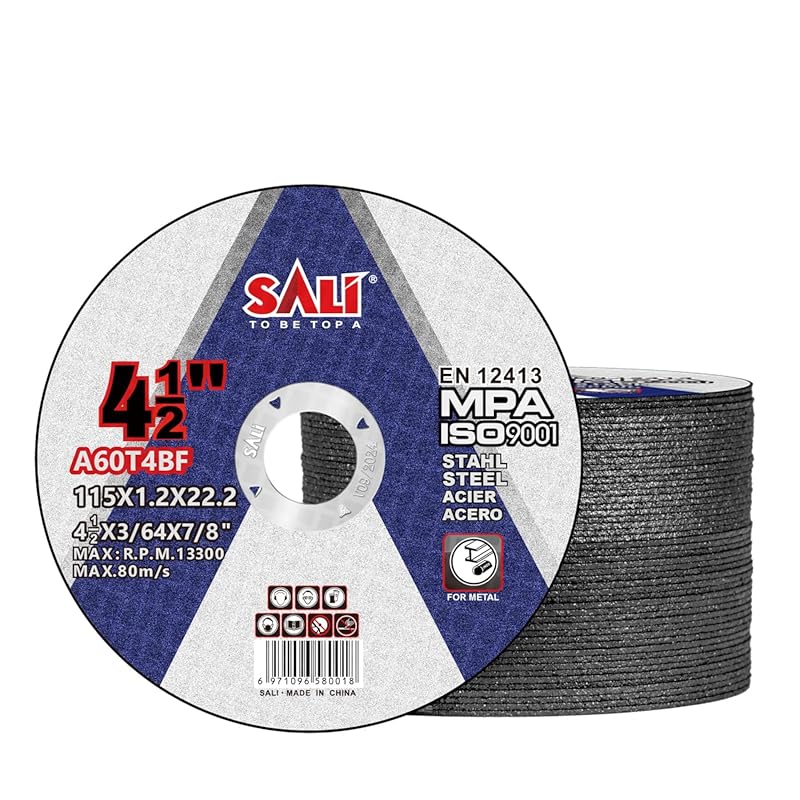

1. 4.5-inch Abrasive Cut-Off Wheels, 50-Pack for Angle Grinders, Fast Cutting Metal and Stainless Steel

This 50-pack of 4.5-inch abrasive cut-off wheels is engineered for angle grinders, delivering lightning-fast cuts on both metal and stainless steel. Featuring an advanced abrasive formula with iridium-coated white and brown alumina, these wheels promise a 30% increase in cutting speed. Their thin profile minimizes friction, resulting in cleaner edges and reduced burr formation, saving you significant post-processing time.

Key Features That Stand Out

- ✓ 30% faster cutting speed for enhanced productivity.

- ✓ Advanced iridium-coated white and brown alumina abrasives for superior performance.

- ✓ Thin profile design ensures cleaner cuts with minimal burrs.

- ✓ Exceptional durability and reliability for consistent daily use.

- ✓ Bulk 50-pack offers great value for frequent users.

Why We Recommend It

We recommend this pack for its outstanding balance of speed, precision, and longevity. The advanced abrasive composition not only slices through tough materials quickly but also leaves a finish that requires less cleanup. Its sheer quantity ensures you’re always stocked for any project.

Best For

Professionals and serious DIYers who demand high-volume, fast, and exceptionally clean cuts on various metal and stainless steel applications.

Pros and Cons

Pros:

- Lightning-fast cutting performance, significantly boosting efficiency.

- Produces remarkably clean cuts with minimal burr, reducing finishing time.

- Enhanced durability from iridium-coated abrasives extends wheel life.

- Cost-effective bulk pack ensures a consistent supply for continuous work.

Cons:

- As an abrasive wheel, it will eventually wear down.

- Thinness requires careful handling to prevent premature breakage.

Customer Reviews

Customer Review: As good or better than many around this $$.Read more

Customer Review: As good or better than many around this $$.Read more

2. EZARC Diamond Abrasive Cut Off Wheel 4 1/2 x 7/8 Inch for Metal, Rebar, Steel, INOX

The EZARC Diamond Abrasive Cut Off Wheel redefines durability and versatility, offering an impressive lifespan equivalent to 100 traditional bonded wheels, translating to over 5,000 cuts on metal. Its advanced diamond technology is suitable for dry cutting a wide array of materials, including rebar, steel, aluminum, and various pipes. Designed with a solid steel body, this wheel significantly enhances safety by reducing the risk of shattering, making it a reliable choice for demanding jobs.

Key Features That Stand Out

- ✓ Diamond technology provides 5,000+ cuts, equating to 100x the life of bonded wheels.

- ✓ Versatile “All in 1 Metal Solution” for cutting rebar, steel, aluminum, and INOX.

- ✓ Solid steel body greatly reduces shatter risk, enhancing user safety.

- ✓ Ideal for dry cutting, eliminating the need for coolant.

Why We Recommend It

For those prioritizing extreme longevity, safety, and broad material compatibility, the EZARC Diamond Abrasive Cut Off Wheel is unmatched. Its diamond technology offers significant long-term cost savings and reduces downtime for wheel changes, making it an efficient investment.

Best For

Professionals and industrial users who frequently cut diverse metal types and seek maximum durability, enhanced safety, and superior cost-per-cut efficiency.

Pros and Cons

Pros:

- Exceptional lifespan, delivering thousands more cuts than standard wheels.

- Highly versatile, suitable for a wide range of metal materials.

- Solid steel body significantly improves safety and durability.

- Offers a much lower cost per cut over its extended service life.

Cons:

- Higher initial purchase price compared to traditional abrasive wheels.

- May not be as aggressively fast for initial penetration as some thin bonded wheels.

Customer Reviews

Customer Review: just received it 10 min ago,and came right on time when i need it,ofcourse i have another ones,but i wanna try this one,what it does i had doubt it will cut thru that metal,but….unfortunatly im speechless,if i say something negative that will be the biggest lie i ever said,no regrets by purchasing t

Customer Review: These EZ Arc Cutting wheels eat through metal like a knife through hot butter !! I thoroughly recommend !!! I use them to cut through hvac housing I go through a Disk about every 2 months it goes through the olde school hvac thicket housings ad well these disks and my 3 1/2” cut off saw have made

3. 50 Pack Abrasive Cut Off Wheels, 4 1/2 Inch for Angle Grinders, Metal & Stainless Steel

This substantial 50-pack of 4.5-inch abrasive cut off wheels is an excellent choice for users needing a reliable supply of discs for their angle grinders. With a thin 0.047-inch profile and proprietary aluminum oxide grain, these wheels are designed for fast, burr-free cutting through various metals and stainless steel. They offer a great combination of performance and value, making them a go-to option for everyday cutting tasks.

Key Features That Stand Out

- ✓ Thin 0.047-inch design for rapid, burr-free cutting.

- ✓ Proprietary aluminum oxide grain ensures aggressive cutting action.

- ✓ Perfectly compatible with standard 4-1/2-inch angle grinders.

- ✓ Large 50-pack quantity provides excellent value and convenience.

Why We Recommend It

This 50-pack stands out for its exceptional cost-effectiveness without sacrificing performance. The thin profile allows for quick, clean cuts, making it a practical choice for workshops and heavy users who need to maintain a steady supply of quality abrasive wheels.

Best For

Contractors, fabrication shops, and dedicated DIY enthusiasts requiring a bulk supply of reliable, fast-cutting wheels for general metal and stainless steel work.

Pros and Cons

Pros:

- Outstanding value and cost-effectiveness in a large 50-pack.

- Thin profile enables fast and exceptionally clean, burr-free cuts.

- Aggressive aluminum oxide grain handles various metal types efficiently.

- Reliable performance for everyday cutting and fabrication tasks.

Cons:

- Lifespan is finite, like all bonded abrasive wheels.

- May not be suitable for extremely specialized or high-wear applications requiring diamond technology.

Customer Reviews

Customer Review: I have used Dewalt, Diablo (the worst), Avanti, and other brands and I can say with confidence these are superior. Their composition is better, more durable, don’t flex as much, and cut faster IF YOU LET THE TOOL DO ITS JOB. That was for the geniuses who burn up tools and tool bits because they’re i

Customer Review: The best discs I’ve ever used, and they wear evenly. I cut 20 old rusted bolts with brackets and I’m still on the first disc.

4. EZARC Abrasive Cut Off Wheels: 3-inch Discs for Metal & Stainless Steel Die Grinders

The EZARC Abrasive Cut Off Wheels in a 3-inch size are specifically designed for die grinders, offering precision and longevity for intricate cutting tasks. Crafted from iridium-plated white corundum, these discs boast twice the cutting life of standard wheels. Their ultra-thin 1/16-inch profile ensures fast, precise, and clean cuts with minimal burr, making them suitable for a wide range of metals including carbon steel, stainless steel, iron, and copper.

Key Features That Stand Out

- ✓ Iridium-plated white corundum provides 2 times the cutting life.

- ✓ Ultra-thin 1/16-inch design for precise, clean, and fast cuts.

- ✓ Minimal burr production reduces post-cut finishing work.

- ✓ Versatile for use on carbon steel, stainless steel, iron, copper, and more.

- ✓ Optimal 3-inch size for die grinders and detailed work.

Why We Recommend It

For jobs requiring finesse and access to tight spaces, these 3-inch EZARC wheels are invaluable. Their extended lifespan and ability to produce exceptionally clean cuts make them a top performer for detailed metal fabrication and repair, ensuring both efficiency and quality.

Best For

Detailed metalworking, automotive repair, fine fabrication, and applications where precision and access with a die grinder are paramount.

Pros and Cons

Pros:

- Extended lifespan (2x standard wheels) means fewer replacements.

- Ultra-thin profile ensures highly precise and clean cuts.

- Excellent for intricate work and accessing confined areas with die grinders.

- Effective on a broad spectrum of common metals.

Cons:

- Smaller diameter limits cutting depth for larger stock.

- Not designed for heavy-duty, large-scale cutting tasks.

Customer Reviews

Customer Review: Great durability. These last a long time, cutting some pretty thick metals. I am very surprised they perform this well for such a reasonable price.

Customer Review: These are the ABSOLUTE best blades available!!!!! Don’t fall for those metal cutoff blades that are GREEN that come from other companies!!!If you like quality and value, then these are for you!!!

5. EZARC 4.5-inch by .045-inch Cut Off Wheels for Metal and Stainless Steel Angle Grinders

The EZARC 4.5-inch by .045-inch Cut Off Wheels are engineered for angle grinders, delivering exceptional performance on both metal and stainless steel. Featuring iridium-plated white corundum, these discs offer twice the cutting life of conventional abrasive wheels. Their ultra-thin .045-inch profile guarantees fast, precise, and clean cuts with minimal burr, making them a highly efficient choice for various cutting applications including carbon steel, stainless steel, iron, and copper.

Key Features That Stand Out

- ✓ Iridium-plated white corundum doubles the cutting life of the disc.

- ✓ Ultra-thin .045-inch profile ensures quick, precise, and clean cuts.

- ✓ Significantly reduces burr formation for less post-processing.

- ✓ Highly versatile for cutting a wide range of ferrous and non-ferrous metals.

- ✓ Standard 4.5-inch size fits most angle grinders.

Why We Recommend It

Combining extended durability with the popular 4.5-inch size, these EZARC cut off wheels are a robust option for general-purpose metal cutting. The enhanced lifespan means fewer interruptions and greater value, while the thin design maintains high cutting speed and quality.

Best For

General metal fabrication, workshop use, and construction tasks where a reliable, long-lasting, and fast-cutting 4.5-inch wheel is essential for daily operations.

Pros and Cons

Pros:

- Doubled cutting life due to premium iridium-plated corundum.

- Ultra-thin profile facilitates rapid and precise cuts with ease.

- Effectively minimizes burr, leading to cleaner finished pieces.

- Versatile application across many metal types including stainless steel.

Cons:

- Higher initial cost compared to basic bulk abrasive wheels.

- Still subject to wear and tear over time, unlike diamond-impregnated blades.

Customer Reviews

Customer Review: Great durability. These last a long time, cutting some pretty thick metals. I am very surprised they perform this well for such a reasonable price.

Customer Review: These are the ABSOLUTE best blades available!!!!! Don’t fall for those metal cutoff blades that are GREEN that come from other companies!!!If you like quality and value, then these are for you!!!

Complete Buying Guide for Abrasive Cut Off Wheel

Essential Factors We Consider

When selecting an abrasive cut off wheel, several crucial factors influence performance and suitability for your task. First, consider the size (diameter and arbor hole), which must match your cutting tool, typically an angle grinder or chop saw. Common diameters include 3, 4.5, 6, 7, 9, 12, and 14 inches. Next, the thickness is vital: thinner wheels (e.g., .045-inch or 1/16-inch) cut faster and with less material loss, producing fewer burrs, but may be less durable. Thicker wheels offer greater durability for aggressive cuts but might generate more heat and burrs.

The abrasive material also plays a significant role. Aluminum oxide is common for general-purpose metal cutting, while zirconia alumina offers enhanced durability and faster cutting for tougher alloys. For ultimate longevity, diamond-impregnated wheels, though more expensive upfront, can last hundreds of times longer than traditional abrasive wheels. Finally, consider the bond type and RPM rating. Ensure the wheel’s maximum RPM rating exceeds your tool’s operating speed to prevent dangerous failures, and select a bond strong enough for your application without being overly rigid.

Budget Planning

Budgeting for abrasive cut off wheels involves more than just the initial purchase price. While a bulk pack of standard aluminum oxide wheels might seem like the cheapest option per disc, consider the overall cost per cut and labor time. Diamond cut-off wheels, despite a higher upfront investment, offer unparalleled longevity and can drastically reduce replacement frequency and downtime, potentially saving money in the long run for heavy users. For intermittent or lighter use, a quality bulk pack of thinner abrasive wheels often provides the best balance of performance and cost.

Also, factor in the cost of post-processing. Wheels that produce minimal burr, such as the thinner or diamond options, can reduce grinding and finishing time, translating into labor savings. Assess your usage frequency and material types to determine if the long-term benefits of a premium or diamond wheel outweigh the lower initial cost of standard abrasive options.

Final Thoughts

Choosing the right abrasive cut off wheel is a critical decision that impacts efficiency, cut quality, and safety in your workshop. Whether you need lightning-fast cuts with minimal burrs for intricate work or unparalleled durability for heavy industrial applications, there’s a specialized wheel for your needs. By considering factors like size, thickness, abrasive material, and your budget, you can select a product that not only meets your requirements but also enhances your overall productivity and ensures a safer working environment. Always prioritize safety gear and follow manufacturer instructions when operating cutting tools.

Frequently Asked Questions

Q: What’s the main difference between abrasive and diamond cut off wheels?

A: Abrasive cut off wheels are made from bonded abrasive grains (like aluminum oxide or zirconia) that wear down over time as they cut. They are relatively inexpensive and are excellent for fast, aggressive cutting. Diamond cut off wheels, however, feature industrial diamonds bonded to a steel core. They cut by grinding away material rather than wearing down significantly themselves, offering extremely long lifespans (hundreds or thousands of times longer than abrasive wheels) and consistent cutting depth, but come with a higher initial cost.

Q: What safety precautions should I take when using cut off wheels?

A: Always wear appropriate Personal Protective Equipment (PPE), including safety glasses or a face shield, hearing protection, gloves, and a dust mask. Ensure the wheel’s RPM rating is higher than your tool’s speed. Inspect wheels for damage before use. Secure your workpiece firmly. Maintain a firm grip on your tool and never force the wheel. Always use the proper guard on your angle grinder or cut-off saw. Keep bystanders clear of the work area.

Q: How do I choose the right size abrasive cut off wheel?

A: The size of the abrasive cut off wheel (diameter and arbor hole) must match the specifications of your cutting tool. Most angle grinders accommodate 4.5-inch or 5-inch wheels, while larger chop saws use 12-inch or 14-inch discs. Ensure the arbor hole matches your tool’s spindle size. Using an incorrect size can lead to unsafe operation and tool damage.

Q: Can I use an abrasive cut off wheel for grinding?

A: No, cut off wheels are specifically designed for cutting (making narrow slits) and generally should not be used for grinding (material removal across a broad surface). Grinding wheels are thicker and engineered to withstand lateral pressure. Using a thin cut off wheel for grinding can cause it to shatter, creating a significant safety hazard. Always use the correct wheel for the intended application.

Q: How long do abrasive cut off wheels typically last?

A: The lifespan of an abrasive cut off wheel varies greatly depending on its quality, thickness, the material being cut, and user technique. Thin, general-purpose wheels might last for several cuts on mild steel, while premium, reinforced wheels designed for stainless steel or tough alloys can last much longer. Diamond cut off wheels will far outlast any traditional abrasive wheel, providing hundreds or even thousands of cuts before needing replacement.

Selecting the ideal abrasive cut off wheel is crucial for efficient and safe metalworking. We hope this comprehensive guide and our top product recommendations help you make an informed decision for your next project. Remember, the best wheel is one that matches your tool, your material, and your specific needs, all while prioritizing safety. Explore our recommended options and get ready to achieve cleaner, faster cuts with confidence!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.