When you’re tackling a flooring project, especially with modern vinyl plank flooring, the right tools make all the difference. While vinyl plank is known for its durability and ease of installation, achieving clean, splinter-free cuts requires a specialized approach. That’s where selecting the best circular saw blade for vinyl plank flooring becomes absolutely critical. Using the wrong blade can lead to chipped edges, melted plastic, and a lot of frustration. Our guide will help you navigate the options to find a blade that delivers precision and efficiency, ensuring your new flooring looks professional and lasts for years.

Quick Product Comparison

Our Top 5 Best Circular Saw Blade For Vinyl Plank Flooring Reviews – Expert Tested & Recommended

1. Diablo PergoBlade Saw Blade for Laminate and Wood Flooring

The Diablo PergoBlade is a standout choice for anyone tackling flooring projects, specifically designed to handle the demanding nature of laminate and vinyl plank flooring. Its specialized construction ensures cleaner cuts and significantly longer life compared to standard blades, making it a favorite among professionals and serious DIYers.

Key Features That Stand Out

- ✓ Features Polycrystalline Diamond (PCD) teeth, offering up to 75 times longer life than standard carbide blades.

- ✓ Engineered for cutting a wide range of flooring, including laminate, engineered wood, bamboo, and hardwood.

- ✓ Incorporates a high-tech anti-kickback design for enhanced safety and smoother, controlled cuts.

- ✓ Laser-cut anti-vibration design minimizes wobbling and noise, ensuring precise cuts every time.

Why We Recommend It

We highly recommend the Diablo PergoBlade for its unmatched durability and precision when working with vinyl plank flooring and other composite materials. The PCD teeth drastically extend the blade’s lifespan, saving you money and time on replacements, while the anti-vibration and anti-kickback features contribute to a safer and more enjoyable cutting experience. It truly delivers exceptional quality and performance for flooring tasks.

Best For

This blade is best for flooring installers, remodelers, and dedicated DIY enthusiasts who frequently cut abrasive materials like vinyl plank, laminate, and engineered wood flooring.

Pros and Cons

Pros:

- Significantly longer lifespan with PCD teeth.

- Produces extremely clean, splinter-free cuts on various flooring types.

- Enhanced safety features like anti-kickback design.

- Reduced vibration for improved accuracy and comfort.

Cons:

- Higher initial cost compared to standard carbide blades.

- Optimized for flooring, less versatile for general wood cutting.

Customer Reviews

Customer Review: “This was my first time dealing with laminate flooring and it went far better than expected. Seems there is a lot of conflicting advice out t”

Customer Review: “Good buy! Better than sacrificing a blade made for wood. Multiple cuts made and still sharp.”

2. WEN 10-Inch 80-Tooth Carbide-Tipped Saw Blade for Ultra-Fine Cuts on Wood and Vinyl.

The WEN 10-inch 80-tooth carbide-tipped saw blade is a fantastic all-rounder for those seeking ultra-fine cuts on a variety of materials, including vinyl plank flooring. Its high tooth count and carbide tips are designed to minimize chipping and provide a smooth finish, making it an excellent choice for detailed work.

Key Features That Stand Out

- ✓ Features an 80-tooth carbide-tipped design for consistently smooth and ultra-fine cuts.

- ✓ Standard 10-inch diameter and 5/8-inch arbor, compatible with most miter and table saws.

- ✓ Utilizes an ultra-thin 1/10-inch kerf (2.4 mm) which reduces material waste and cutting effort.

- ✓ Highly versatile, capable of slicing cleanly through both hard and softwoods of all kinds, as well as vinyl.

Why We Recommend It

We recommend the WEN 80-tooth blade as an editor’s choice because it strikes an impressive balance between performance and value. It delivers the kind of clean, efficient cuts needed for vinyl plank flooring without requiring a specialized, expensive blade. Its versatility also means it can handle other woodworking tasks with ease, making it a great addition to any workshop.

Best For

This blade is ideal for hobbyists, DIYers, and light-duty professionals who need precise, splinter-free cuts on both wood and vinyl plank flooring projects.

Pros and Cons

Pros:

- Delivers ultra-fine, smooth cuts, reducing chipping on vinyl.

- Good value for a high-tooth-count carbide blade.

- Versatile for cutting various wood types in addition to vinyl.

- Thin kerf promotes efficiency and less material waste.

Cons:

- Not specifically optimized for extremely dense engineered flooring like PCD blades.

- 10-inch size might be too large for compact handheld circular saws.

Customer Reviews

Customer Review: “This is a decent 80 tooth carbide blade at a very attractive price. I’m not making fine furniture for a living, and am not overly concerned about minimizing cutting time, tooth marks or sanding time, so very expensive blades are largely wasted on me. And having said that, this blade delivers a very”

Customer Review: “Works great, still going, sharp, strong great quality for the price. Cuts accurately for 1/8 the cost od DW junk”

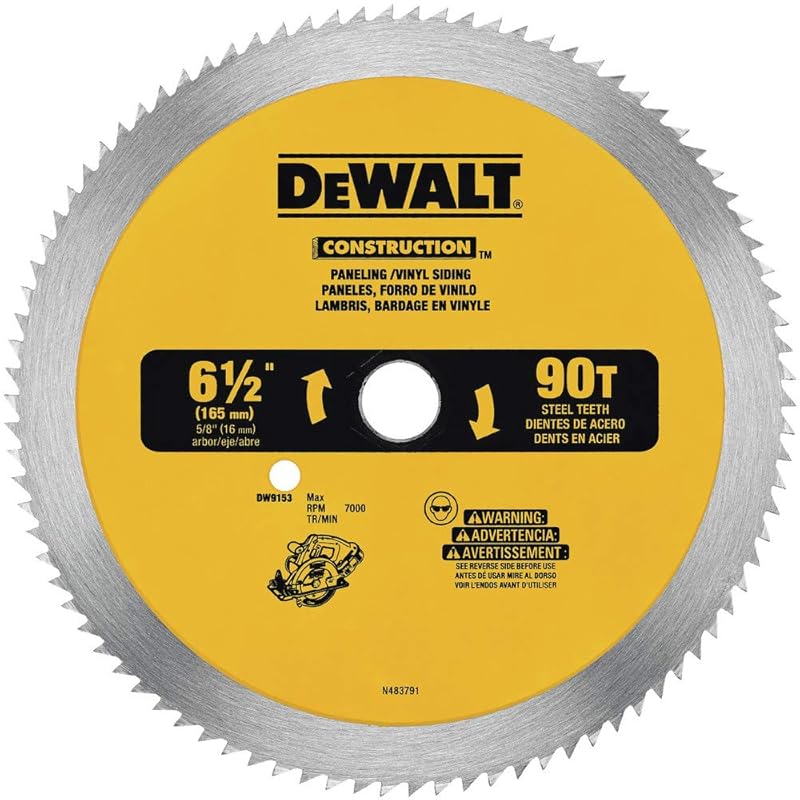

3. DEWALT Circular Saw Blade, 6 1/2 Inch, 90 Tooth, Vinyl Cutting

The DEWALT 6 1/2 Inch, 90 Tooth Circular Saw Blade is specifically engineered for cutting vinyl, making it an excellent budget-friendly choice for vinyl plank flooring installations. Its high tooth count combined with durable construction ensures clean, smooth cuts without breaking the bank, offering reliable performance from a trusted brand.

Key Features That Stand Out

- ✓ Features a high 90-tooth count specifically optimized for cutting vinyl and similar plastics.

- ✓ Constructed with tougher tungsten carbide, ensuring the blade stays sharper for an extended period.

- ✓ Includes a specially formulated anti-stick coating that minimizes friction and gum-up for smoother operation.

- ✓ Designed with a thin kerf, promoting fast, efficient, and clean cutting action.

Why We Recommend It

We recommend this DEWALT blade as our best budget option because it offers specialized performance for vinyl plank flooring at an accessible price point. The 90-tooth design and anti-stick coating are crucial for achieving the clean edges needed on vinyl, preventing melting and chipping, all within a compact and manageable size for portable circular saws.

Best For

This blade is perfect for DIYers and professionals focused primarily on installing vinyl plank flooring and cutting vinyl siding, especially those utilizing 6 1/2-inch cordless circular saws.

Pros and Cons

Pros:

- Excellent performance and clean cuts specifically on vinyl materials.

- Durable tungsten carbide teeth for prolonged sharpness.

- Anti-stick coating helps prevent material buildup and friction.

- Thin kerf design enhances cutting speed and efficiency.

Cons:

- Less versatile for heavy-duty wood framing or ripping tasks.

- Smaller diameter limits cutting depth on some projects.

Customer Reviews

Customer Review: “Gets the job done for vinyl siding. Decided to turn the blade backwards per recommendations.”

Customer Review: “This is a 5 3/8″, 10mm arbor, 80 tooth, clockwise cutting circular saw blade for finishing work. I used it on a Milwaukee M12 Fuel cordless circular saw it to cut wood wall panels and 1/2″ thick baseboard trim. The blade cuts very smoothly and very cleanly. There aren’t many blades to choose from”

4. FOXBC 10-Inch 200-Tooth Saw Blade for Smooth Cuts on Plastic and Vinyl Flooring.

The FOXBC 10-Inch 200-Tooth Saw Blade is engineered for achieving the absolute smoothest cuts possible on delicate materials like plastic and vinyl plank flooring. With an incredibly high tooth count, this blade virtually eliminates splinters and rough edges, ensuring a pristine finish every time.

Key Features That Stand Out

- ✓ Features an exceptionally high 200-tooth count for ultra-smooth, splinter-free cuts on sensitive materials.

- ✓ Ideal for precise cutting of Plywood, OSB, Plastic, Paneling, and Vinyl Siding/Flooring.

- ✓ Designed with a 5/8″ arbor and 0.1″ kerf, suitable for many standard table and miter saws.

- ✓ Guarantees beautiful, clean miter edges and cross-cuts in materials prone to chipping.

Why We Recommend It

This FOXBC blade is a top recommendation for its ability to deliver unparalleled smoothness on vinyl plank flooring. When you absolutely need to avoid any chipping, melting, or rough edges, its 200-tooth configuration ensures a factory-like finish. It’s perfect for detailed work where a flawless edge is paramount.

Best For

This blade is best suited for meticulous DIYers and professionals who prioritize flawlessly smooth, splinter-free cuts on vinyl plank flooring, plastics, and delicate paneling.

Pros and Cons

Pros:

- Achieves extremely smooth, pristine cuts, eliminating splinters.

- Specifically designed to excel on plastics and vinyl.

- Thin kerf minimizes material loss.

- Provides clean miter edges and cross-cuts.

Cons:

- Very high tooth count can result in slower cutting speeds.

- Not suitable for aggressive cutting of thick hardwoods or framing.

Customer Reviews

Customer Review: “As advertized, good product and good price.Read more”

Customer Review: “As advertized, good product and good price.Read more”

5. SKIL 4-3/8-Inch 40-Tooth Carbide Saw Blade for Clean Cuts on Vinyl Flooring.

The SKIL 4-3/8-Inch 40-Tooth Carbide Saw Blade is a compact powerhouse, ideal for those using smaller circular saws for precise cuts on materials like vinyl plank flooring. Its thoughtful design, including a thin kerf and anti-kickback features, ensures clean, accurate, and safe operation for everyday flooring tasks.

Key Features That Stand Out

- ✓ Features a thin kerf design that allows the blade to spin faster and cut easier, optimizing performance for both cordless and corded saws.

- ✓ Equipped with anti-kickback shoulders that provide stability and help ensure straight, accurate cuts without unexpected kickback.

- ✓ Incorporates expansion slots designed to reduce blade vibration, contributing to a straighter and truer cutting path.

- ✓ Its 40-tooth carbide tips are specifically designed to provide clean and efficient cuts on vinyl flooring and similar materials.

Why We Recommend It

We recommend the SKIL 4-3/8-inch blade for its excellent performance on vinyl plank flooring, particularly for those using compact or specialized saws. It combines essential features like a thin kerf and anti-kickback design, which are crucial for safety and achieving clean results on vinyl, making it a reliable and effective choice for precise flooring cuts.

Best For

This blade is ideal for homeowners and DIYers using compact circular saws or trim saws for installing vinyl plank flooring and other trim work where precision and maneuverability are key.

Pros and Cons

Pros:

- Thin kerf design enhances cutting efficiency, especially for cordless tools.

- Anti-kickback shoulders and expansion slots improve safety and accuracy.

- Provides clean, precise cuts on vinyl flooring.

- Compact size is perfect for smaller, more maneuverable saws.

Cons:

- Lower tooth count (40T) might not be as smooth as 80T+ blades for ultra-fine finishes on very delicate vinyl.

- Limited to smaller circular saw applications.

Customer Reviews

Customer Review: “Great balance of price to blade life. If you have not cut flooring before and are cutting engineered hardwood / pergo etc…. you will find out quickly that it is very tough stuff ! Blade performs very well on Pergo XP and bamboo. In fact, it appears to last about as long as $25.00 makita blade. I'”

Customer Review: “I use these blades all the time and they tend to last pretty long.”

Complete Buying Guide for Best Circular Saw Blade For Vinyl Plank Flooring

Choosing the best circular saw blade for vinyl plank flooring isn’t just about grabbing the first blade you see. Vinyl plank, while resilient, can be tricky to cut cleanly without the right blade. Let’s break down the essential factors we consider to help you make an informed decision.

Essential Factors We Consider

When selecting a blade for vinyl plank flooring, several key features contribute to a clean, efficient, and safe cut:

- Tooth Count (TPI – Teeth Per Inch): For vinyl, a higher tooth count is almost always better. Blades with 60 teeth or more for a 7.25-inch blade, or 80+ teeth for a 10-inch blade, will provide smoother cuts and significantly reduce chipping, melting, or tearing of the material. More teeth mean smaller bites and less aggression on the material.

- Blade Material and Tips: Carbide-tipped (CT) blades are standard and perform well. For ultimate durability and longevity, especially if you’re frequently cutting tough materials, Polycrystalline Diamond (PCD) tipped blades, like the Diablo PergoBlade, offer superior wear resistance.

- Kerf (Blade Thickness): A thin-kerf blade (typically 1/10-inch or less) is highly recommended. Thin kerfs reduce the amount of material removed, lessening friction and heat build-up, which is crucial for preventing the vinyl from melting and sticking to the blade. It also requires less power from your saw.

- Hook Angle: A negative or low positive hook angle is generally preferred for plastics and non-ferrous metals, as it reduces the aggressiveness of the cut, minimizing chipping and melting.

- Anti-Kickback and Anti-Vibration Features: These are not just safety features but also contribute to cut quality. Anti-kickback designs prevent the blade from binding, while anti-vibration slots keep the blade stable, leading to straighter, cleaner cuts and a more comfortable user experience.

- Blade Diameter: Ensure the blade diameter matches your circular saw’s specifications. Common sizes for circular saws are 6 1/2 inches, 7 1/4 inches, and 10 inches.

Budget Planning

When budgeting for a circular saw blade for vinyl plank flooring, it’s wise to consider the trade-off between upfront cost and long-term performance. While budget blades are tempting, they might lead to frustrating results and quicker wear, requiring more frequent replacements. Investing a bit more in a high-quality, specialized blade, particularly one with a high tooth count and carbide or PCD tips, can save you time, improve the quality of your cuts, and ultimately extend the life of your blade. Think of it as an investment in a smoother, more professional-looking finished floor.

Final Thoughts

Ultimately, the best circular saw blade for vinyl plank flooring is one that provides clean, splinter-free cuts, reduces friction and melting, and matches your specific saw and project needs. Prioritize blades with a high tooth count, a thin kerf, and durable carbide or PCD tips. Always remember to wear appropriate safety gear, including eye protection and hearing protection, and ensure your blade is sharp and correctly installed before making any cuts.

Frequently Asked Questions

Q: What tooth count is best for cutting vinyl plank flooring?

A: For vinyl plank flooring, a high tooth count blade (60-tooth or more for 7.25-inch, 80-tooth or more for 10-inch) is generally recommended. More teeth mean finer, smoother cuts and less chipping or melting of the vinyl.

Q: Can I use a standard wood blade for vinyl plank flooring?

A: While you technically can, a standard wood blade (especially one with fewer teeth) will likely result in rougher cuts, chipping, or even melting the vinyl due to friction. It’s best to use a blade specifically designed for or highly suited to plastic/vinyl for the best results on vinyl plank flooring.

Q: Why do some blades melt vinyl?

A: Melting occurs due to excessive friction and heat. Blades with fewer teeth, larger gullets, or incorrect tooth geometry can generate more heat, causing the vinyl to melt rather than cut cleanly. A thin kerf blade with a high tooth count helps minimize this.

Q: What’s the difference between a carbide-tipped and a PCD blade?

A: Carbide-tipped blades are very common, offering good durability and sharpness. PCD (Polycrystalline Diamond) blades are significantly harder and more durable, making them ideal for extremely abrasive materials like cement board and some composite laminates, lasting much longer but at a higher cost. For typical vinyl plank flooring, high-quality carbide is often sufficient, but PCD offers ultimate longevity.

Q: Should I cut vinyl plank flooring face up or face down?

A: Generally, it’s recommended to cut vinyl plank flooring face up with a circular saw. This ensures that the cleanest side of the cut (where the blade enters) is on the visible surface of the plank, minimizing tear-out or chipping on the finished face.

Choosing the right circular saw blade for your vinyl plank flooring project doesn’t have to be a daunting task. By focusing on blades with high tooth counts, thin kerfs, and durable materials, you can ensure clean, professional-looking cuts every time. Our top recommendation, the Diablo PergoBlade, stands out for its exceptional longevity and performance, but all the blades reviewed offer distinct advantages depending on your specific needs and budget. Take your time, consider the features that matter most to you, and invest in a blade that will make your flooring installation smooth and successful. Happy cutting!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.