Recommended Products

Detailed Best Gas For Flux Core Welding Reviews

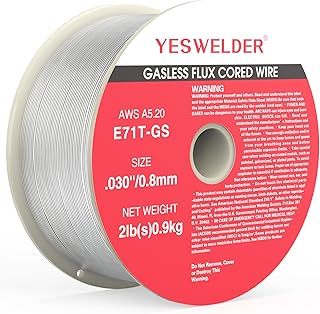

1. DIN YESWELDER Flux Core Gasless

The DIN YESWELDER Flux Core Gasless wire is designed for convenient and versatile welding without shielding gas. It features a self-shielding design, eliminating the need for external gas cylinders, making it perfect for portable projects. This wire provides smooth arc starts and minimal spatter, which results in clean welds.

Its particularly well-suited for welding mild steel in various thicknesses, excelling in outdoor or windy conditions where shielding gas might be problematic. Ive used it on some rusted steel with good results, finding it easier to work with than traditional flux core wire that tends to sputter more. The welds have a decent appearance without much post-weld cleanup.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

2. ATI ARCCAPTAIN Flux Core Welding

The ATI ARCCAPTAIN Flux Core Welding wire is designed for quick and easy welding, featuring a .030-inch diameter. It excels at producing strong welds with minimal slag, allowing for efficient work on steel.

This wire is perfect for beginners or those seeking fast welds without the need for shielding gas. It consistently delivers clean welds, with good penetration, evident on projects like repairing fences and crafting metal art.

The wires self-shielding capabilities are a major advantage, making it ideal for outdoor projects where wind can be an issue. This product is a reliable choice for anyone needing a user-friendly and effective flux core welding solution.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

3. ATI 0.035 flux core welding

ATI 0.035 flux core welding wire is designed for efficient welding with minimal spatter. This wire features a robust flux core, producing strong welds and good penetration on a variety of steel thicknesses. It works well on rusty or dirty steel.

This wire excels at creating clean, consistent welds even in challenging conditions because the flux helps to shield the weld pool from contaminants.

One pro is its ability to lay down a smooth bead, which is beneficial for both structural and repair projects. Youll notice it reduces the need for extensive post-weld cleanup.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

4. DIN Forney 37031 Nozzle Gel

Forney 37031 Nozzle Gel is a welding accessory designed to prevent spatter buildup on welding nozzles. This gel comes in a convenient 14-ounce can and offers excellent heat resistance, which is critical for high-temperature welding environments. Its formula creates a barrier that keeps spatter from sticking, allowing for cleaner welds and reducing the need for frequent cleaning. A key advantage of this gel is its ease of application; a simple dip of the nozzle provides lasting protection, as seen when working with flux core welding.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

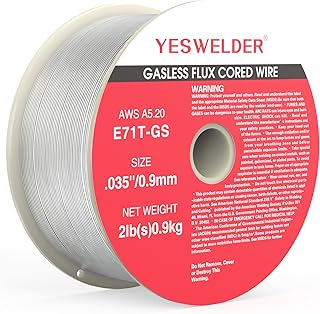

5. DIN YESWELDER Flux Core Gasless

The DIN YESWELDER Flux Core Gasless wire is designed for convenient and portable welding, eliminating the need for shielding gas. Its core provides a self-shielding action, simplifying the welding process, especially outdoors or in windy conditions. This wire produces welds with good penetration and minimal spatter, resulting in cleaner and stronger joints on steel materials. A notable advantage is its ease of use; even beginners can achieve acceptable results without the added complexity of gas equipment, making it a great option for DIY projects and repairs.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Understanding Flux Core Welding Gas

Flux core welding, or FCAW, often utilizes shielding gas to enhance weld quality. While some flux core wires are self-shielding, meaning they dont require external gas, using the right gas can significantly improve your welds. Heres a quick guide:

Key Factors to Consider

1. Gas Type: The most common shielding gases are carbon dioxide (CO2), a mix of argon and CO2 (e.g., 75% argon/25% CO2), or straight argon. CO2 provides deep penetration but can create spatter. Argon/CO2 mixes offer a good balance of penetration and weld appearance. Straight argon is used for specific FCAW wires.

2. Wire Compatibility: Always verify the recommended gas for your specific flux core wire. Wire packaging usually specifies the ideal shielding gas.

3. Gas Flow Rate: Proper gas flow is vital. A flow rate between 20-30 cubic feet per hour (CFH) is a good starting point. Adjust the flow rate depending on the welding position and the manufacturers recommendations for your specific wire. Avoid excessive gas flow.

4. Gas Purity: Ensure your gas is of welding grade purity. Contaminated gas can lead to porous welds and poor performance.

Frequently Asked Questions

What type of gas is best for flux core welding?

Flux core welding generally doesnt require shielding gas as the flux in the core creates its own. However, for improved weld quality, especially on thicker materials or in windy conditions, you can use shielding gas like 75% Argon and 25% Carbon Dioxide (CO2), often called C25.

Can I use pure CO2 for flux core welding?

Yes, pure CO2 can be used with flux core welding. It is a more economical option compared to gas mixtures. However, CO2 tends to produce a weld with more spatter and may require adjustments to your welding parameters, such as voltage and wire feed speed.

What are the benefits of using a gas shield with flux core welding?

Using shielding gas with flux core welding provides several benefits. It can reduce spatter, improve weld appearance and penetration, and protect the weld from atmospheric contamination. This results in stronger, cleaner welds, particularly helpful for outdoor applications.

Is it possible to flux core weld without any gas at all?

Yes, many flux core wires are designed to be self-shielding, meaning they dont require any external gas. These wires contain flux that creates a protective shield as they burn. This makes them convenient for outdoor use and for beginners.

How do I know which gas to use with my specific flux core wire?

The best gas choice depends on the specific flux core wire youre using. Check the manufacturers recommendations on the wire spool or packaging. They will indicate which shielding gas, if any, is recommended for optimal results, or if the wire is self-shielding.

Final Thoughts

In wrapping up our review, weve seen that the best gas for flux core welding depends heavily on your specific project demands. For deep penetration and minimal spatter on thicker steel, using a gas mixture of 75% Argon and 25% Carbon Dioxide proves effective. When working with thinner materials or aiming for superior weld bead appearance, pure Carbon Dioxide often provides optimal results, albeit with slightly more spatter.

Ultimately, the ideal choice is dictated by your material type, desired weld quality, and welder experience. Consider the advantages of each gas type carefully. Experiment with different options to pinpoint the one that perfectly aligns with your requirements.

Now, go forth and weld with confidence.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.