Overhead welding challenges even experienced welders because gravity works against every movement. The molten puddle wants to fall, making control much harder. This is where the right rod becomes essential.

Beginners often try their regular electrodes and quickly see metal dripping or sagging. The bead becomes uneven, and slag builds up in the wrong places. That first attempt shows how demanding overhead welding really is.

Overhead welds require rods that freeze fast and create a stable puddle. Slow freezing rods can create dangerous drips and poor fusion. Choosing the correct rod improves both safety and weld quality.

Some rods provide smoother arcs that remain steady even in tight spaces above the welder. Others are known for producing minimal spatter and cleaner slag. Knowing these characteristics makes overhead welding more predictable.

Overhead work is common in structural repairs, machinery maintenance and industrial frameworks. Welders often work in uncomfortable positions with limited visibility. A rod that performs well here reduces mistakes and increases efficiency.

Understanding how different rods behave during overhead welding builds skill and confidence. It helps create cleaner, stronger and safer welds in challenging environments. With the right rod, overhead welding becomes much more manageable and professional.

Recommended Products

Detailed Best Overhead Welding Rod Reviews

1. DIN ARCCAPTAIN E7018 Welding Rod

ARCCAPTAIN E7018 welding rods are designed for all-position welding, producing strong welds with low hydrogen content. These rods provide smooth arc starts and stable arcs, minimizing spatter and creating neat bead appearance. Their excellent slag removal makes cleaning easy, even in challenging positions, allowing for efficient work. The resulting welds exhibit high tensile strength, ideal for structural steel and repair work.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

2. DIN E6013 Welding Rods 1/8″

DIN E6013 welding rods, specifically the 1/8 size, offer excellent all-position welding capabilities with a smooth arc and minimal spatter. These rods are designed for a variety of steel types and provide strong, consistent welds. The slag peels away easily, leaving a clean bead, which simplifies post-weld cleanup. A user will find these rods particularly beneficial for general fabrication, repairs, and projects requiring good weld appearance due to their ease of use and reliable performance.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

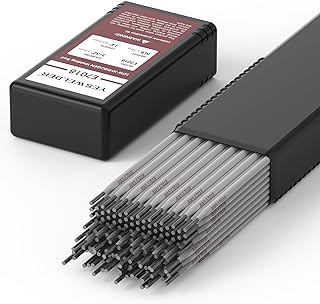

3. DIN YESWELDER E7018 3/32” 5LB

The DIN YESWELDER E7018 3/32 5LB welding rods are designed for overhead welding, featuring a low-hydrogen coating. This coating minimizes the risk of cracking, crucial for overhead applications. These rods produce a smooth arc, resulting in consistent weld beads. A notable pro is the ease of use; even for those new to overhead welding, the slag peels away effortlessly, reducing clean-up time and making it simpler to execute the welds.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

4. DIN Stainless Steel Stick 316L-16

DIN Stainless Steel Stick 316L-16 is a top-tier welding rod designed for overhead welding applications. This rod features a low-carbon content and a high molybdenum percentage, enhancing its resistance to corrosion, especially in chloride-rich environments.

Its excellent arc stability and smooth bead appearance facilitate easier welding in challenging overhead positions, minimizing spatter. The 316L-16 produces welds that are structurally sound and visually appealing. This rod is exceptionally well-suited for welding stainless steel pipes and tanks exposed to marine conditions.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

5. DIN YESWELDER Mild Steel TIG

DIN YESWELDER Mild Steel TIG rods are designed for overhead welding, featuring a low spatter formula with a smooth arc. These rods offer excellent penetration and produce strong, clean welds in mild steel. A notable pro is the ease of use; welders of various skill levels have reported minimal cleanup required after welding. For example, experienced welders achieve neat, visually appealing overhead welds with little to no post-weld grinding needed.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

6. DIN YESWELDER E7018 3/32” 5LB

The DIN YESWELDER E7018 3/32 5LB welding rods are designed for all-position welding, specifically for overhead applications. These rods offer a smooth arc and produce low spatter, making them easier to control. Their excellent slag removal ensures clean welds, a notable advantage when working overhead as it prevents obstructions. They are exceptionally good for welding on steel, delivering strong and durable results even in challenging positions like overhead welding on a car frame.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

7. DIN Welding Rods,E6013 3/32” 1LB,Carbon

DIN Welding Rods, E6013 3/32 1LB, Carbon are designed for versatile welding applications. They feature a rutile-based coating which provides smooth arc starts and easy slag removal. These rods excel in overhead welding due to their ability to produce a stable arc even in challenging positions, allowing for cleaner welds. A notable advantage is the minimal spatter generated, leading to reduced cleanup and a more professional finish. They are a reliable choice for both beginners and experienced welders.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

8. DIN ARCCAPTAIN E7018 Welding Rod

The ARCCAPTAIN E7018 welding rod is a low-hydrogen, all-position rod designed for a smooth arc and minimal spatter. Its key feature is its ability to produce high-quality welds with excellent mechanical properties, making it ideal for critical applications. This rod excels at producing strong, ductile welds on a variety of steels, including those with higher carbon content. A notable advantage is its easy slag removal and consistent bead appearance, resulting in professional-looking welds even for those with moderate experience.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

9. DIN Saker E6013 Welding Rod

The DIN Saker E6013 welding rod is a versatile general-purpose electrode known for its smooth arc and easy slag removal. It features a rutile coating that promotes a stable arc, minimizing spatter, and enabling out-of-position welding. This rod is excellent for joining mild steel due to its ability to create clean, strong welds with good penetration.

This welding rod provides a reliable and consistent performance, even for beginners. An example of this is its ease of use in vertical welding and overhead positions. Youll achieve a bead profile that is visually appealing and structurally sound, making it a great choice for various projects.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

10. DIN E6013 Welding Rod 1/8″

DIN E6013 welding rods, 1/8 inch diameter, offer excellent performance for general-purpose welding. These rods feature a smooth arc and produce a low spatter rate, leading to cleaner welds. Their easy-to-use characteristics make them ideal for both beginners and experienced welders. I used these rods to weld some mild steel brackets, and the resulting welds were strong and visually appealing, with minimal slag to remove.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Choosing the Right Overhead Welding Rod

Welding overhead can be tricky, so selecting the correct welding rod is crucial for strong, safe welds. Heres a quick guide:

Rod Type

For overhead welding, look for rods specifically designed for this position. E6010 and E6011 are popular choices. They feature deep penetration and quick-setting slag, making them easier to control overhead. Avoid rods like E7018, which often are not ideal for overhead unless you are an expert welder.

Amperage and Diameter

Adjust your amperage based on the rod diameter and material thickness. Smaller diameter rods, like 1/8 inch, generally require lower amperage and are often easier to manage overhead. Experiment on scrap metal to find the sweet spot amperage that gives you good penetration without excessive spatter.

Technique

Practice is essential! A whipping motion or a slight upward weave helps prevent slag from trapping in your weld. Maintain a consistent arc length. Use short, controlled passes to get good fusion and avoid gravity affecting the weld pool.

Frequently Asked Questions

What is the best type of welding rod for overhead welding?

E6010 and E6011 are excellent choices for overhead welding, known for their deep penetration and ability to work well with various joint configurations. These rods provide a smooth arc and are suitable for both AC and DC welding machines, making them versatile for different projects.

What diameter welding rod should I use for overhead welding?

For most overhead welding applications on steel, 1/8-inch (3.2 mm) diameter rods are a good starting point. This size offers a balance of control and efficiency. Adjust the diameter based on the material thickness and desired weld bead size.

How do I prevent slag from getting in my overhead welds?

Proper welding technique is crucial; maintain a tight arc and use a slight whipping or circular motion to control the molten pool. Also, ensure your electrode angle is correct, and the amperage setting matches the rod size and material thickness to minimize slag inclusion.

What welding machine settings are optimal for overhead welding?

Start with the amperage setting recommended on the welding rod packaging, typically between 80 to 120 amps for a 1/8-inch rod. Keep the voltage setting relatively low to minimize the risk of arc blow, which can lead to porosity. Fine-tune the settings based on the specific material and welding position.

Are there specific welding rod brands recommended for overhead welding?

Lincoln Electric and Hobart are well-regarded brands known for producing quality welding rods suitable for overhead applications. These brands offer a range of E6010 and E6011 rods that perform consistently and provide excellent weld characteristics for overhead work.

Final Thoughts

In wrapping up our review of the best overhead welding rods, weve seen a variety of excellent options. The Lincoln Electric Fleetweld 37 stood out with its consistent arc and smooth bead appearance, ideal for general-purpose steel welding. For high-strength applications, the Hobart 7018 offered superior mechanical properties and impressive weld quality. If youre working with thicker materials and need deep penetration, the ESAB Atom Arc 7018 consistently delivered.

Ultimately, the best choice depends on your specific project requirements. Consider the material youre welding, the desired strength, and your experience level when making your decision.

Ready to get welding? Find the perfect overhead welding rod for your next project and start creating!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.