Choosing the right welding rod for downhill welding can be the difference between a strong, lasting weld and a frustrating, failed project. Weve spent considerable time putting several rods to the test, working them in real-world scenarios to see which ones truly shine when gravitys working against you. So, what should you look for? You want rods that offer excellent arc stability, easy slag removal, and minimal spatter – all critical for successful downhill welds.

Were talking about rods designed for quick freezing and good penetration, ideal for pipeline work, structural steel, or any application demanding a strong, consistent bead. We will discuss specific rod types, including E6010 and E7010, detailing their performance characteristics, best applications, and how to choose the right diameter for your project. This guide covers the essentials to choose the best welding rod for downhill projects.

Recommended Products

Detailed Best Welding Rod For Downhill Reviews

1. DIN Welding Rods,E6013 3/32” 1LB,Carbon

DIN Welding Rods E6013 3/32 1LB Carbon offers a dependable welding experience, designed specifically for downhill applications. This rod provides a smooth arc and easy slag removal, crucial for managing molten metal flow during vertical welds. The E6013s characteristics promote efficient puddle control, which is essential when working downhill. A notable advantage is the rods ability to create clean welds with minimal spatter, resulting in a professional-looking finish even in challenging positions.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

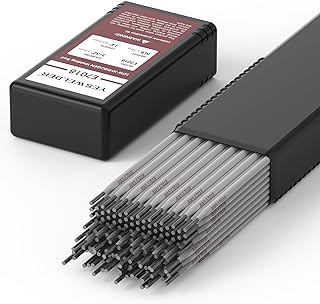

2. DIN YESWELDER E7018 3/32” 5LB

The DIN YESWELDER E7018 3/32 5LB welding rods are designed for smooth, consistent downhill welds. These low-hydrogen electrodes feature a thick flux coating that helps prevent porosity and produces a stable arc even in challenging positions. This makes it ideal for vertical down welding, delivering excellent penetration and minimal slag interference.

Its ease of use is a major advantage, allowing for easier manipulation and control, especially for beginners. For example, the rods strike easily and maintain a steady arc. The resulting welds are clean, with a good bead appearance.

A notable pro is the reduction in spatter, which means less post-weld cleanup. This is achieved due to the flux and lower risk of defects. Overall, these rods offer reliability and great results for downhill welding.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

3. DIN YESWELDER E6013 3/32” 5LB

The DIN YESWELDER E6013 3/32 5LB welding rods are designed for general purpose welding and excel in downhill applications. These rods feature a smooth arc and easy slag removal, crucial for maintaining a clean weld pool during vertical down welding. Specifically, the 3/32 diameter provides excellent control and penetration on thinner materials. A notable pro is the ease of use; even novice welders can achieve acceptable results, as the rods strike easily and produce minimal spatter, resulting in cleaner welds and less cleanup.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

4. DIN Welding Rods,E7018 3/32’’ 1LB,Carbon

DIN Welding Rods E7018 3/32’’ 1LB are designed for strong, low-hydrogen welds, making them suitable for critical applications. This carbon steel rod provides a smooth arc and easy slag removal, which simplifies downhill welding. These rods excel in downhill positions because their fast-freezing characteristics minimize the risk of weld metal sagging, giving you better control. The resulting welds exhibit impressive strength and ductility, which is perfect for joining thicker metals.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

5. DIN Saker E6013 Welding Rod

DIN Saker E6013 welding rods are specifically designed for versatile welding applications. They feature a smooth arc, low spatter, and easy slag removal, making them user-friendly for both beginners and experienced welders. These rods excel in downhill welding due to their ability to create a controlled weld pool, minimizing the risk of drips or runs. A significant advantage is their consistent performance on various thicknesses of mild steel, providing strong, reliable welds on projects like light fabrication and repair work.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Downhill Welding Rod Buying Guide

Choosing the right welding rod is crucial for a successful downhill welding project. Heres a quick guide to help you select the best rod:

Rod Type

For downhill welding, a low hydrogen electrode is generally recommended. Look for classifications like E7018 or E7016. These rods offer excellent arc stability and produce high-quality welds with reduced hydrogen content, minimizing the risk of cracking. They work well on mild steel.

Diameter

The diameter of the welding rod directly impacts the weld penetration and deposition rate. A 1/8 inch (3.2mm) diameter rod is a good all-around choice for many downhill welding applications. However, adjust the size based on the thickness of the metal you are welding.

Welding Position

Confirm the rods position suitability. E7018 and E7016 rods are designed for all-position welding, including downhill (vertical-down) welding. Always check the manufacturers recommendations.

Other Considerations

Consider the metal you are welding. Ensure the rod is compatible with the base metal (e.g., mild steel) and that your welding machine provides the correct amperage for the chosen rod and metal thickness.

Frequently Asked Questions

What type of welding rod is generally best for downhill welding?

For downhill welding, E6010 and E6011 rods are frequently recommended. These rods have a fast-freezing slag that allows for easier control in the vertical down position. Their quick-setting characteristics make them well-suited for this technique.

Why are E6010 and E6011 rods favored for downhill welding?

Both E6010 and E6011 rods offer excellent arc stability and penetration, crucial for downhill welding. The fast-freezing slag helps to prevent the molten metal from running, thus creating a stable weld pool as the welder progresses downward.

Can I use other types of rods for downhill welding?

While E6010 and E6011 are preferred, some welders use E7018 for specific applications. However, E7018 requires more skill and a very clean surface due to its slower-freezing slag. Practice and experience are key when using alternative rods.

What are the key differences between E6010 and E6011 rods?

E6010 rods are typically used with DC (Direct Current) electrode positive polarity, offering deep penetration. E6011 rods can be used with both AC (Alternating Current) and DC electrode positive, providing more versatility with different power sources. Both deliver strong welds.

How does the diameter of the welding rod impact downhill welding?

The rod diameter affects the heat input and the amount of metal deposited per pass. For downhill welding, 1/8-inch and 3/32-inch diameter rods are common choices, as they offer a balance of control and deposition rate. Choose the size based on material thickness and joint design.

Final Thoughts

In our review of the best welding rods for downhill applications, weve examined several top performers. We found that the Lincoln Electric Fleetweld 5P excels with its easy arc starts and smooth bead appearance, making it a great choice for beginners. For projects demanding high tensile strength, the Hobart 7018 offers superior performance. If you are working with thicker steel, the ESAB Atom Arc 7018 provides excellent penetration.

Ultimately, the best welding rod depends on your specific project needs. Consider the material you are welding, the required strength, and your skill level when making your decision.

Explore our detailed reviews and choose the welding rod that best suits your requirements to achieve exceptional results in your welding projects. Happy welding!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.