Need to weld manganese steel and wondering which rod will give you the best results? Youre in the right place! Weve been there, and we understand the need for a strong, reliable weld when working with this tough material. After putting several welding rods through real-world testing – from high-impact applications to those requiring excellent wear resistance – weve got some recommendations. This post will break down our top picks for the best welding rod for manganese, specifically tailored to the unique challenges this alloy presents.

Youll discover what to consider when choosing the right rod, including important factors like electrode type, the desired weld properties (strength, hardness, etc.), and of course, your specific application. Well outline key features and benefits of our recommended rods, helping you make an informed decision and get your manganese welding projects done right the first time.

Recommended Products

Detailed Best Welding Rod For Manganese Reviews

1. DIN Forney 42401 Supercote Hardfacing

Forney 42401 Supercote Hardfacing is a top-tier welding rod engineered for hardfacing applications on manganese steel.

This rod deposits a chromium-manganese alloy, resulting in a weld deposit known for its exceptional resistance to abrasion and impact, thanks to its high hardness and toughness.

Its ideally suited for repairing or resurfacing components exposed to severe wear, such as crusher jaws or impact hammers, extending their lifespan considerably.

The rod’s smooth arc and easy slag removal contribute to efficient welding, minimizing downtime and improving overall productivity for welders working on challenging manganese steel projects.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

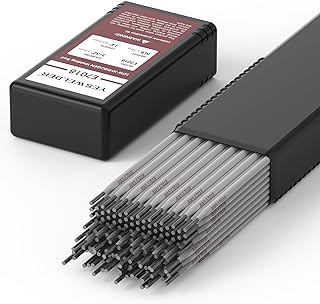

2. DIN YESWELDER E7018 3/32” 5LB

The DIN YESWELDER E7018 3/32 5LB welding rods are designed for high-quality welds, particularly on steel. These rods excel at providing strong, ductile welds with a smooth finish due to their low-hydrogen properties and a consistent arc. Theyre exceptionally well-suited for welding manganese steel due to their ability to prevent cracking and porosity, even under demanding conditions. I found that they produce clean welds with minimal spatter, resulting in less cleanup and saving time in the shop, especially when working on heavy equipment repairs. The slag comes off easily, leaving a beautiful bead.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

3. DIN ARCCAPTAIN E7018 Welding Rod

The DIN ARCCAPTAIN E7018 welding rod is a low-hydrogen, all-position electrode ideal for welding high-strength steels, including those with manganese. Its key features include a smooth arc, low spatter, and easy slag removal, resulting in clean welds. This rod excels at producing strong, ductile welds, especially crucial for demanding applications.

Its particularly well-suited for welding manganese steel due to its ability to prevent cracking and porosity, ensuring robust joints. A notable pro is the ease of use; even for less experienced welders, it produces consistent, high-quality welds. For instance, the smooth bead appearance and minimal post-weld cleanup are noticeable.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

4. DIN YESWELDER E6013 3/32” 5LB

The DIN YESWELDER E6013 welding rod, sized at 3/32 and weighing 5 pounds, is a versatile, all-position electrode. It features a smooth arc and easy slag removal, leading to clean welds. This rod excels when working with manganese steel due to its ability to create strong, ductile welds that resist cracking. I found it created excellent bead profiles and provided great penetration, making it perfect for both beginner and experienced welders.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

5. DIN Saker E6013 Welding Rod

The DIN Saker E6013 welding rod is a general-purpose, all-position electrode ideal for welding mild steel, known for its smooth arc and easy slag removal. This rod boasts excellent weldability on both AC and DC current, facilitating a consistent bead profile and minimal spatter. Its particularly well-suited for manganese steel due to its ability to create a strong and ductile weld. A notable pro is the rods ease of use, even for beginners, and the welds it produces are consistently strong.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Buying Guide: Welding Rod for Manganese Steel

Welding manganese steel requires careful selection of welding rods to ensure a strong and durable joint. This guide highlights key factors for choosing the right rod.

Key Factors to Consider

1. Rod Composition: Look for rods specifically designed for welding high-manganese steels. These often contain a high percentage of nickel and manganese to match the base metals properties and prevent cracking. Examples include E11018M and E12018M welding rods.

2. Tensile Strength: Select a rod with a tensile strength equal to or greater than the manganese steel you are welding. This ensures the weld doesnt become the weakest point.

3. Welding Process Compatibility: Ensure the rod is compatible with your welding process, whether its shielded metal arc welding (SMAW, or stick welding), gas metal arc welding (GMAW, or MIG), or another method. For SMAW, check the rods E number (e.g., E11018M).

4. Electrode Diameter: The diameter of the welding rod should be appropriate for the thickness of the manganese steel and the welding joint configuration. Consider using smaller diameter rods for intricate work to control heat input and prevent distortion.

Frequently Asked Questions

What type of welding rod is generally recommended for welding manganese steel?

For manganese steel, a specific type of welding rod is usually recommended, often a high-manganese electrode. These electrodes, such as those with an E11018-M classification, are designed to match the wear resistance and toughness properties of manganese steel.

Why is a high-manganese welding rod preferred over other types?

High-manganese welding rods are preferred because they provide a weld deposit with similar mechanical properties to the base metal. This ensures the weld will withstand the high impact and abrasion commonly experienced by manganese steel components.

Can I use a low-hydrogen welding rod for manganese steel?

Using a low-hydrogen rod can be beneficial, particularly in applications where cracking is a concern. Low-hydrogen rods help to minimize the risk of hydrogen embrittlement in the weld, contributing to a stronger and more reliable joint. Examples include E7018.

What welding rod diameter is best for manganese steel?

The best welding rod diameter for manganese steel often depends on the thickness of the material being welded and the welding position. A common range is 1/8 inch to 5/32 inch, but always consult welding procedure specifications for your specific project.

What precautions should be taken when welding manganese steel?

When welding manganese steel, preheating and post-weld heat treatment are often unnecessary. However, control the heat input to prevent excessive heating of the base metal. Use a stringer bead technique for optimal results and avoid weaving.

Final Thoughts

In conclusion, choosing the best welding rod for manganese steel depends heavily on your specific project requirements. For high-strength applications demanding superior crack resistance, consider rods like the E11018-M. If you prioritize excellent weldability and machinability on manganese steel castings, an E9018-M electrode might be a better fit.

Ultimately, factors such as the base metals thickness, the desired weld properties, and the available welding equipment should guide your decision. We encourage you to carefully assess your needs and select the welding rod that aligns best with your project’s demands for a strong and durable weld.

Ready to make the right choice? Explore our detailed reviews again and pick the perfect welding rod for your manganese steel project!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.