Ready to tackle some body panel welding? Choosing the right welding wire is crucial for a smooth, professional finish. For thin sheet metal, youll want to lean towards a wire specifically designed for that purpose to minimize burn-through and warping.

Weve put various wires to the test, welding everything from minor rust repairs to complete panel replacements. After hours of arc time, we found some clear winners. Youre probably wondering: What diameter wire is best? What about the shielding gas? And what brands should you trust?

In this post, well break down our top picks, detailing the pros and cons of each, so you can confidently choose the right wire for your project and get those body panels looking their best. Get ready to learn about the best welding wire for body panels!

Recommended Products

Detailed Best Welding Wire For Body Panels Reviews

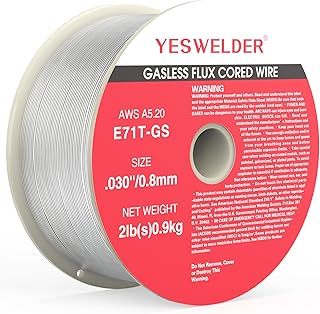

1. DIN YESWELDER Flux Core Gasless

DIN YESWELDER Flux Core Gasless welding wire is a solid choice for body panel work.

This wire is designed to be used without shielding gas, making it convenient for mobile repairs or situations where gas isnt readily available. It produces a clean, consistent weld, with minimal spatter.

The flux core helps to protect the weld from contamination and contributes to a smoother bead profile, making it easier to work with. Ive found it excellent for filling small holes and patching rust spots on older cars.

The wires performance makes it a good option for those seeking an easy-to-use, gasless solution for auto body projects.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

2. DIN Demon ER70S6 .030

DIN Demon ER70S6 .030 welding wire is a premium choice for automotive body panel work.

This wire features a high silicon and manganese content, which promotes excellent deoxidation and provides a smooth, stable arc.

Its precise composition allows for clean welds with minimal spatter, essential for thin sheet metal.

The resulting welds are strong and easily feathered, making it ideal for repairs and restorations, ultimately reducing the need for extensive grinding.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

3. DIN Solid MIG Welding Wire

DIN Solid MIG Welding Wire is a high-quality wire specifically designed for welding automotive body panels. This wire offers excellent arc stability, producing smooth, consistent welds with minimal spatter. Its precise composition ensures great penetration and strength, vital for structural repairs on cars.

The wires properties make it ideal for thin sheet metal, preventing burn-through and distortion. I used this wire to repair rust damage on a vintage car, and the welds were clean and easy to grind, allowing for seamless blending. The wire feeds smoothly, making it suitable for both experienced and novice welders.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

4. DIN PGN Solid MIG Welding

DIN PGN Solid MIG Welding wire is specifically designed for automotive body panel work.

This wire features a smooth, consistent feed, minimizing spatter and producing clean welds. It excels with thin gauge steel, critical for body panel repairs, allowing for easy manipulation.

Its excellent arc stability makes it easy to control, preventing burn-through and distortion.

I found the wire delivered professional-quality results on my old car restoration, seamlessly filling gaps.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

5. DIN PGN Solid MIG Welding

DIN PGN solid MIG welding wire is designed specifically for auto body panel work.

This wire features a smooth copper coating and is typically available in 0.8mm diameter, ensuring excellent arc stability and minimal spatter.

Its composition allows for superior penetration and clean welds, making it ideal for thin gauge steel commonly found in car bodies.

Pros include easy feeding and consistent results, evident when welding complex curves, and ensuring that the final result is easy to grind and paint.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

6. ATI ARCCAPTAIN Mig Welding Wire,

ATI ARCCAPTAIN Mig Welding Wire is specifically engineered for automotive body panel repairs, offering a .030-inch diameter. This wire features a copper coating that promotes excellent arc stability and smooth feeding, minimizing spatter. The low-spatter formula and easy-to-manage bead makes it ideal for thin gauge steel common in car bodies, allowing for precise welds. For example, it easily fills small holes and joins panels seamlessly without excessive grinding.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

7. ATI ARCCAPTAIN Mig Welding Wire,

ATI ARCCAPTAIN Mig Welding Wire is specifically designed for welding sheet metal body panels. This wire, typically a .030 or .035 inch diameter, offers excellent arc stability and smooth feeding. Its copper-coated composition resists rust and provides superior corrosion resistance. This results in minimal spatter and clean welds, making it ideal for auto body repair. The wires consistent performance allows for easily creating strong, professional-looking welds, even for beginners.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

8. DIN Solid MIG Welding Wire

DIN Solid MIG Welding Wire is a high-quality wire specifically designed for welding automotive body panels. It features a consistent diameter of 0.8mm, crucial for achieving precise welds on thin sheet metal. This wires composition provides excellent arc stability and minimal spatter, which is essential for clean welds that require less grinding. A notable advantage is the ease with which it produces smooth, strong welds, allowing for easy filling of gaps and superior overall finish compared to cheaper alternatives. The results are particularly evident in the final appearance, with less distortion and a better surface for paint.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

9. DIN YESWELDER ER70S-6 MIG Wire,

The DIN YESWELDER ER70S-6 MIG Wire is a premium welding wire specifically designed for automotive body panel repairs. It features a high silicon and manganese content, which provides excellent deoxidizing properties, reducing porosity and ensuring strong welds. This wire excels at producing clean, smooth welds on thin sheet metal, crucial for body panel work.

Its ability to handle rust and contaminants effectively is a major advantage, making it ideal for the often-dirty environment of auto body shops. Welds lay down beautifully, with minimal spatter, allowing for easier grinding and finishing.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

10. ATI ARCCAPTAIN Flux Core Welding

The ATI ARCCAPTAIN flux core welding wire is designed for body panel work, boasting a 0.030-inch diameter. This wire features a self-shielding flux core, eliminating the need for shielding gas.

It excels at creating clean, strong welds on thinner sheet metal, crucial for auto body repairs.

A notable pro is its ease of use, even for beginners, thanks to its smooth feeding and minimal spatter.

The resulting welds are generally sound and ready for grinding and finishing, saving time and effort.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Choosing the Right Welding Wire for Body Panels

When repairing car body panels, selecting the correct welding wire is crucial for a strong and rust-resistant finish. Heres what to consider:

Wire Composition

For most auto body work, choose wire labeled ER70S-6. This wire is specifically designed for welding mild steel, which is common in car bodies. It contains higher levels of deoxidizers and silicon to produce cleaner welds, and is suitable for thin gauge sheet metal. Avoid wires designed for different metal types.

Wire Diameter

Use a smaller diameter wire, such as .023 or .024. This allows for better control and less heat input, reducing the risk of burning through thin metal panels. Thinner wires also make it easier to weld in all positions.

Shielding Gas Compatibility

ER70S-6 wire typically requires a shielding gas of 75% Argon / 25% Carbon Dioxide or 100% Carbon Dioxide. Make sure your gas setup is compatible with the selected wire and your welding machine.

Spool Size and Storage

Buy spools of wire that you can use in a reasonable amount of time. Properly store welding wire in a dry environment to prevent rust and maintain its welding performance.

Frequently Asked Questions

Whats the best welding wire diameter for auto body panel work?

For most auto body panel repairs, a wire diameter of 0.023 or 0.025 is generally recommended. These thinner wires provide better control and minimize the risk of burn-through on thin sheet metal. They also produce cleaner welds that require less grinding.

Should I use solid or flux-cored wire for welding body panels?

Solid wire is usually preferred for body panel welding due to the cleaner welds it produces and the reduced spatter. This type of wire requires a shielding gas, typically a blend of argon and carbon dioxide. Flux-cored wire can be used, especially in windy conditions or when a gas supply isnt available, but it often results in more cleanup.

What type of shielding gas is best for welding auto body panels?

A shielding gas mixture of 75% argon and 25% carbon dioxide (C02) is a popular choice for welding mild steel body panels. This gas blend provides good weld penetration and bead appearance. Pure argon is often used with stainless steel and aluminum.

Which wire is best for welding steel body panels?

ER70S-6 welding wire is an excellent choice for welding steel auto body panels. This wire contains higher levels of deoxidizers and produces strong, clean welds, reducing the chance of porosity. Always check the wires compatibility with the steel type you are welding.

How important is the wires composition for body panel welding?

The wires composition is very important; it impacts the welds strength, corrosion resistance, and overall quality. ER70S-6 wire offers good results on common auto body steels. Always select a wire specifically designed for the type of metal you are welding to ensure optimal results.

Final Thoughts

In wrapping up, weve explored several excellent welding wire options for automotive body panels. For those prioritizing a smooth, low-spatter bead, consider Lincoln Electrics SuperArc L-56, known for its excellent performance on mild steel. If you frequently work with thinner materials, Hobarts FabShield 21B offers good results. For those needing something versatile, the Blue Demon 70S-6 is reliable on a variety of steel types.

Ultimately, the best wire hinges on your specific projects and the materials youre using. Factor in your welding experience and desired weld characteristics when making your selection. Consider these top-rated products based on your specific requirements. We hope this review guides you towards a better welding experience. Good luck and happy welding!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.