Looking to weld your exhaust? Choosing the right welding wire is crucial for a strong, lasting repair. For exhaust systems, you need wire that can handle high heat and resist corrosion. Weve put several options to the test, and the results are in! Specifically, we found that ER70S-6 welding wire consistently delivers excellent performance due to its higher manganese and silicon content. This results in cleaner welds that are less prone to porosity. Youll also find that 309 stainless steel wire works well, especially for joining dissimilar metals.

Youre probably wondering what makes a good exhaust welding wire. Durability, ease of use, and resistance to rust are key considerations. Well cover the best wires to use, how to identify them, and what to avoid to make the right choice.

Recommended Products

Detailed Best Welding Wire For Exhaust Reviews

1. DIN EWCS 1/0 Gauge Premium

DIN EWCS 1/0 Gauge Premium welding wire is a heavy-duty cable designed for demanding applications, featuring a substantial 1/0 gauge size and constructed with high-quality copper conductors.

This robust wire excels in exhaust systems due to its ability to handle high temperatures and provide excellent current carrying capacity.

The superior conductivity of the copper ensures minimal voltage drop, delivering consistent power to your welder even over long distances.

Many users report successful welds using this cable, indicating that this wire is a dependable choice for projects that require reliability and performance.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

2. DIN EWCS Gauge Premium Extra

DIN EWCS Gauge Premium Extra welding wire is engineered for high-performance exhaust system repairs, featuring a copper-coated, carbon steel composition.

Its precise gauge and formulation ensure excellent penetration and robust weld strength, vital for withstanding extreme temperatures and vibrations.

This wire minimizes spatter and promotes smooth arc starts, leading to cleaner welds and reduced post-weld grinding.

Specifically, the copper coating improves corrosion resistance, extending the lifespan of the repair, and examples include it being great for patching mufflers or headers with minimal fuss.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

3. ATI ARCCAPTAIN Stainless Steel MIG

The ATI ARCCAPTAIN Stainless Steel MIG wire is designed specifically for welding exhaust systems. This wire boasts a 308L stainless steel composition, making it highly resistant to corrosion and high temperatures common in exhaust applications. It provides excellent weldability, creating strong, durable joints that are less prone to cracking or rust. A notable advantage is the smooth arc it produces, resulting in clean welds with minimal spatter, which is essential for working on vehicle exhaust systems. Ultimately, this MIG wire offers a reliable solution for exhaust repairs and modifications, ensuring long-lasting performance.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

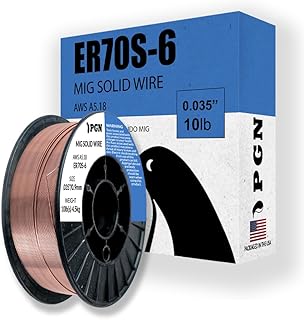

4. DIN PGN Solid MIG Welding

DIN PGN Solid MIG Welding wire is engineered specifically for exhaust systems. This wire offers excellent corrosion resistance, thanks to its high-quality stainless steel composition, ideal for the harsh environments exhaust components face. The wires smooth feeding characteristics contribute to consistently clean welds with minimal spatter. A notable pro is its ability to penetrate deeply, ensuring strong, durable welds that withstand high temperatures and vibration, preventing future exhaust leaks and failures.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

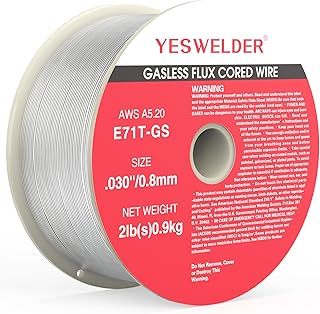

5. DIN YESWELDER Flux Core Gasless

DIN YESWELDER Flux Core Gasless welding wire provides a strong, reliable weld specifically for exhaust systems. Its flux-cored design eliminates the need for shielding gas, making it incredibly convenient for outdoor or mobile repair work. This wire excels at penetrating through rusty or contaminated exhaust components. I used it to repair a severely rusted muffler, and the welds held up perfectly under significant heat and vibration, demonstrating its durability.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

6. DIN Demon ER70S6 .030

DIN Demon ER70S6 .030 welding wire is a premium choice for exhaust system repairs. It features a copper coating for excellent arc stability and smooth feeding through the welding gun. The high silicon and manganese content in the wire promotes strong, durable welds, which is ideal for the high temperatures and stresses of exhaust systems. This wire consistently produces clean welds with minimal spatter, as demonstrated when repairing a rusted exhaust manifold, resulting in a solid, airtight seal.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

7. ATI ARCCAPTAIN Flux Core Welding

ATI ARCCAPTAIN Flux Core Welding Wire is a solid choice for exhaust work. This wire is specifically designed for welding mild steel, which is common in exhaust systems. Its flux core produces a strong weld, even on dirty or rusty surfaces, which is very helpful when dealing with old exhaust components. A notable pro is the wires ability to create a smooth, spatter-free bead, making cleanup minimal. It produces excellent welds that hold well under heat and vibration, contributing to a lasting exhaust repair.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

8. DIN YESWELDER Stainless Steel MIG

The DIN YESWELDER Stainless Steel MIG welding wire is designed for exhaust system repairs, featuring a .030 diameter for precise welds. Its constructed of high-quality stainless steel, ensuring excellent corrosion resistance against exhaust fumes and harsh weather.

This wire is ideal for welding exhaust components because of its ability to create strong, durable bonds that can withstand high temperatures and vibration.

A notable advantage is its smooth feeding through the MIG welder, minimizing spatter and allowing for clean, professional-looking welds, even on thin-walled tubing.

The wires arc stability contributes to easy starting and consistent penetration, resulting in a reliable exhaust repair.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

9. DIN Demon ER308L .030 2LB

DIN Demon ER308L .030 2LB is a stainless steel welding wire ideally suited for exhaust systems. This wire offers a diameter of .030 inches and comes in a 2-pound spool, providing ample material for smaller repair jobs. Its low carbon content (the L in ER308L) minimizes the risk of carbide precipitation, resulting in superior corrosion resistance, especially crucial in exhaust environments. This wire produces clean, strong welds, allowing for reliable repairs on exhaust manifolds and pipes that withstand high heat and exposure to the elements.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

10. DIN PGN Solid MIG Welding

DIN PGN Solid MIG Welding wire is a premium choice, offering excellent performance for exhaust system repairs. It features a solid core construction and a precise copper coating, ensuring a stable arc and smooth wire feed. This wire excels in welding mild steel commonly found in exhaust systems, producing strong, durable welds. A significant advantage is its ability to resist corrosion and create clean welds, making it perfect for the challenging environment of an exhaust system; this is why welders often find its performance superior.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Choosing the Right Welding Wire for Your Exhaust System

Welding exhaust systems requires the correct wire to ensure durability and prevent rust. Several factors are crucial in your selection.

Material Compatibility

The exhaust systems material dictates your wire choice. For stainless steel exhaust components, choose a stainless steel welding wire like ER309L or ER309. These offer excellent corrosion resistance. For mild steel systems, use ER70S-6 wire.

Wire Diameter

Wire diameter affects weld penetration and the overall welds strength. Use a smaller diameter wire, like 0.030 or 0.035, for thinner exhaust tubing. For thicker materials, consider 0.045 or 0.052 diameter wire.

Welding Process

Match your welding wire to your equipment. Gas Metal Arc Welding (GMAW/MIG) often uses solid wire. Choose a wire specifically designed for the shielding gas you plan to use, typically Argon or a mix of Argon and CO2.

Frequently Asked Questions

What is the best welding wire for exhaust systems?

For exhaust systems, the best choice is typically a stainless steel welding wire, such as 309L or 308L. These wires offer excellent corrosion resistance and strength, crucial for withstanding high temperatures and exposure to the elements that exhaust systems experience.

Can I use regular steel wire to weld an exhaust?

While you can technically weld an exhaust with regular steel wire, its not recommended. Regular steel wire lacks the corrosion resistance of stainless steel, leading to premature rust and failure of the exhaust system. This can lead to costly repairs and even safety concerns.

What diameter wire should I use for exhaust welding?

A wire diameter of 0.030 or 0.035 is commonly used for exhaust welding. These diameters provide a good balance between weld penetration and control, making them suitable for the thinner materials often found in exhaust systems. Consider your welding machines capabilities when choosing a wire size.

Do I need a specific shielding gas for exhaust welding?

Yes, for stainless steel wire, youll need a shielding gas like argon or a mixture of argon and carbon dioxide. Argon provides good shielding against atmospheric contamination, resulting in cleaner, stronger welds. A mix can increase penetration but could also lead to oxidation if not done right.

How do I prepare the exhaust for welding?

Thoroughly clean the exhaust components before welding. Remove any rust, dirt, or grease from the welding area using a wire brush or grinder. Proper cleaning ensures a strong, reliable weld and prevents contaminants from compromising the welds integrity.

Final Thoughts

In wrapping up our review of the best welding wire for exhaust systems, weve seen a variety of excellent choices. For stainless steel applications, the Hobart 308L Stainless Steel wire delivers exceptional corrosion resistance and strong welds. If youre working with mild steel, the Lincoln Electric ER70S-6 provides a reliable and cost-effective solution, known for its good penetration. For exhaust systems with high heat, consider a wire designed for those demands.

Ultimately, the best welding wire depends on your specific needs and the metals youre working with. Carefully consider the material of your exhaust components and desired strength before making your selection. Ensure you pick the right wire for successful, long-lasting repairs or builds. Now, start welding and get that exhaust back in top shape!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.