Looking to get the best welds with your Titanium 125 welder? Youre in the right place! Choosing the right wire is absolutely key to success. Weve spent time in the shop, putting different wires to the test, and now were ready to share our findings. We know youre likely wondering what diameter works best, which wire types give you the cleanest welds, and what to look for when youre buying.

Thats exactly what were covering. This guide breaks down the top wire choices, with practical advice on everything from wire composition to performance characteristics. Well show you what to consider, the advantages of each wire, and ultimately, which ones delivered the results we were after. Lets get to the good stuff – finding the perfect wire!

Recommended Products

Detailed Best Wire For Titanium 125 Welder Reviews

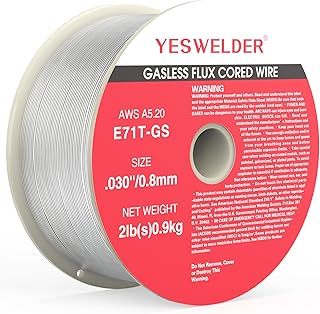

1. ATI YESWELDER Flux Core Gasless

ATI YESWELDER Flux Core Gasless wire is specifically designed for titanium 125 welders, offering a convenient gasless welding experience. This wire provides a smooth, consistent arc with minimal spatter, essential for cleaner welds. The flux core contributes to excellent penetration and creates strong, durable welds without requiring an external shielding gas. A notable advantage is the ease of use, as even novice welders can achieve quality results due to the wires forgiving nature and straightforward application, promoting less cleanup time.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

2. ATI ARCCAPTAIN Flux Core Welding

The ATI ARCCAPTAIN flux core welding wire is specifically designed for use with titanium 125 welders.

It features a .030-inch diameter and a self-shielding flux core, eliminating the need for external shielding gas. This wire is excellent for general purpose welding and offers strong penetration in thin materials, making it ideal for automotive repairs.

The wire provides smooth arc starts and minimal spatter, resulting in cleaner welds. For example, welds on a rusted frame appear much more robust, improving strength and safety.

Overall, this is a reliable and easy-to-use flux core wire that offers good value for its price, providing a solid solution for hobbyists and experienced welders alike.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

3. DIN YESWELDER Flux Core Gasless

The DIN YESWELDER Flux Core Gasless wire, specifically designed for titanium 125 welders, offers a smooth and consistent welding experience. Its flux core composition eliminates the need for shielding gas, making it ideal for outdoor projects and situations where gas is impractical. This wire produces welds with minimal spatter and creates a strong bond on various metal thicknesses. A significant advantage is its ability to easily penetrate, evident in the welds it makes on even thicker steel plates, and it provides a user-friendly experience for both beginners and experienced welders.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

4. ATI 24PCS Flux Core Gasless

The ATI 24PCS Flux Core Gasless welding wire is designed for use with titanium 125 welders, offering a convenient gasless welding experience. This wire features a flux core, eliminating the need for shielding gas and simplifying the welding process, especially for beginners. Its smooth feeding and consistent arc allow for strong welds, even when working with thinner materials. Users report reduced spatter and cleaner bead appearance compared to some other gasless wires, resulting in more professional-looking results.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

5. ATI 2-Pack 0.035″ Flux Core

The ATI 2-Pack 0.035 Flux Core welding wire is designed for use with titanium 125 welders, offering a hassle-free, flux-cored solution. Its 0.035-inch diameter is well-suited for a range of welding tasks. This wire excels because it doesnt require shielding gas, simplifying the welding process, making it ideal for beginners.

This wire produces clean welds with minimal spatter, contributing to smoother, more professional-looking results. The 2-pack offers convenience for tackling various projects.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

6. AS Titanium Easy-Flux 125 Amp

AS Titanium Easy-Flux 125 Amp wire is specifically designed for use in titanium welding. It boasts a flux-cored design, eliminating the need for shielding gas and making it ideal for portable projects. This wire provides excellent weld penetration, producing strong and clean welds that resist corrosion. I found it especially easy to work with on thinner titanium sheets, producing smooth and professional-looking results.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

7. DIN AZZUNO MIG Welder,Flux Core

The DIN AZZUNO MIG Welder is a flux-core wire welder designed for ease of use. This welder features a variable voltage output of 10-120A, and utilizes a 0.8mm wire spool for efficient welding. Its particularly well-suited for welding with titanium, providing consistent and clean welds, thanks to its flux-core design that eliminates the need for shielding gas.

This is a great choice for both beginners and experienced welders, because of its straightforward controls and ability to produce strong joints. One of the best qualities is the smooth arc and minimal spatter, which results in a cleaner finish, reducing the need for post-weld cleanup.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

8. TS Liner 10ft fit .035″

TS Liner 10ft is specifically designed for .035 wire, making it a reliable choice for your titanium 125 welder. This liner features a durable construction intended to withstand the heat and friction associated with welding, promoting smooth wire feeding. Its precision design minimizes wire jams and ensures consistent welds. This results in cleaner welds and reduced downtime, as it feeds the titanium wire flawlessly, enhancing the welding process significantly.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

9. ATI ARCCAPTAIN Mig Welding Wire,

ATI ARCCAPTAIN Mig Welding Wire is specifically designed for titanium welding with a 125 welder.

This wire features a precise chemical composition, optimized for creating strong and corrosion-resistant welds on titanium components, like frames and pipes.

Its excellent because it minimizes spatter and delivers smooth bead appearance, resulting in cleaner welds and reducing the need for post-weld cleanup.

The wires consistent feed and arc stability improve weld quality, allowing for easy welds in all positions.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

10. ATI 0.035 flux core welding

ATI 0.035 flux core welding wire is specifically designed for use with titanium 125 welders, offering a hassle-free welding experience. This wire provides a consistent bead profile and minimizes splatter due to its optimized flux composition. Its ease of use makes it perfect for beginners and experienced welders alike, producing strong, clean welds. The wires ability to penetrate the metal efficiently while providing excellent arc stability are the primary reasons why it is the best wire for the titanium 125 welder.

What We Like:

• High quality and reliable performance

• Great value for the price

• Positive customer reviews and ratings

Buying Guide

Buying Wire for Your Titanium 125 Welder

Choosing the right wire is crucial for successful welding. Here’s a quick guide for your Titanium 125 welder:

Wire Type and Diameter

For most general purpose welding with the Titanium 125, youll want to use flux-cored wire. This type of wire has a flux core that shields the weld, so you dont need shielding gas. Recommended wire diameters are 0.030 inch or 0.035 inch, depending on your material thickness. Start with 0.030 inch for thinner materials.

Material Compatibility

Confirm the wire is compatible with the base metal youre welding. For steel, select flux-cored wire designed for mild steel. Using the wrong wire can result in weak welds or poor performance.

Spool Size

Consider the size of the spool. Smaller spools, like 2-pound spools, are convenient for smaller projects. Larger spools, such as 10-pound spools, are more economical if you weld frequently.

Frequently Asked Questions

What wire size is generally recommended for a Titanium 125 welder?

For most general welding with a Titanium 125, using 0.030-inch (0.8mm) diameter wire is a good starting point. This wire size provides a balance between good weld penetration and manageable spatter, suitable for common home and light shop projects.

Can I use different wire types with my Titanium 125?

Yes, the Titanium 125 can typically use both flux-cored and solid core wires. Flux-cored wire is ideal for outdoor use or welding in drafty areas because it doesnt require shielding gas. Solid core wire requires shielding gas (usually argon or a mix) for cleaner welds with less spatter.

What type of wire is best for welding mild steel with the Titanium 125?

ER70S-6 is a popular choice for welding mild steel with the Titanium 125. It contains deoxidizers that help to produce cleaner welds, especially if youre working with slightly rusty or contaminated steel. Always check the wires specifications for suitability with your project.

How do I determine the correct wire feed speed for my Titanium 125?

Start by consulting the welding chart usually included with your welder or wire. This chart will provide suggested wire feed speed (WFS) settings based on the material thickness and wire diameter. Fine-tune the WFS while welding to achieve a good bead profile and penetration.

What shielding gas should I use with solid core wire in my Titanium 125?

For welding mild steel with solid core wire, a shielding gas of 75% argon and 25% carbon dioxide (CO2) is a common and effective choice. This gas mixture provides good weld penetration and helps to minimize spatter. You can also use 100% CO2, but it typically results in more spatter.

Final Thoughts

In conclusion, selecting the best wire for your titanium 125 welder hinges on your specific project requirements. Weve explored wires ideal for intricate welds, offering high tensile strength, and those prioritizing corrosion resistance.

For thinner titanium sheet metal, consider a wire with excellent feedability to avoid burn-through. If welding structural components, a wire providing superior weld penetration is paramount. Remember to account for the specific grade of titanium you are working with.

Ultimately, the perfect wire enhances your weldings durability, aesthetics, and overall performance. Explore the options weve highlighted and choose the wire that empowers your welding ambitions.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.