Ever tried to cut metal with your stick welder and ended up frustrated? You’re not alone. Choosing the right cutting rods can feel like navigating a maze. There are so many types, and picking the wrong one can lead to messy cuts, wasted time, and even safety problems.

Many welders wonder: “Which rod will give me a clean cut without all the extra effort?” It’s a common question because the wrong rod makes a simple job feel impossible. You want your metal to be cut precisely, not jagged or uneven. This is where understanding cutting rods for stick welding becomes super important.

In this post, we’ll break down the world of cutting rods. You’ll learn what makes them different and how to pick the best one for your specific project. By the end, you’ll feel confident in your choice and ready to tackle any cutting job. Let’s dive into finding the perfect rod for your stick welder!

Our Top 5 Cutting Rods For Stick Welder Recommendations at a Glance

Top 5 Cutting Rods For Stick Welder Detailed Reviews

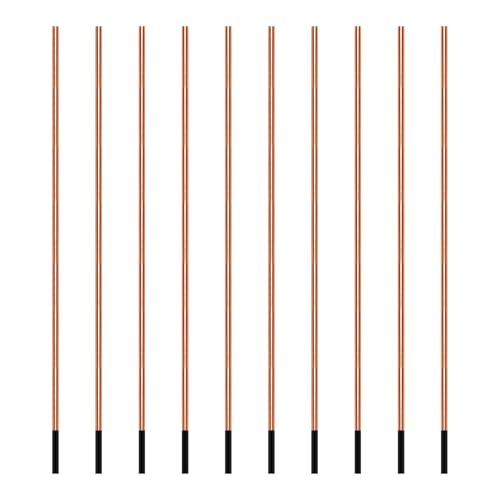

1. PATIKIL 10pcs 6mmx305mm(1/4″x12″) Carbon Arc Air Gouging Rods Copper Graphite Coated Gouging Electrode Rods for Welding

Rating: 8.8/10

Looking for reliable tools to shape metal for your welding projects? The PATIKIL 10pcs 6mmx305mm Carbon Arc Air Gouging Rods are designed for just that. These rods are made from a special blend of copper and graphite, then coated with copper after being heated to a super high temperature. This makes them tough and good at conducting electricity, so they won’t break easily and work quietly. They’re perfect for cutting metal into the exact shapes you need before you weld.

What We Like:

- These rods are built tough with high-temperature resistance, meaning they last longer.

- Their copper coating helps them conduct electricity well, which is important for smooth cutting.

- They don’t make a lot of noise when you use them, making your work environment more pleasant.

- The rods are not easy to break, so you can count on them for your jobs.

- They are a great consumable for carbon arc gouging, widely used in important industries like shipbuilding and bridge construction.

What Could Be Improved:

- Remember to keep these rods dry. If they get wet, you need to dry them out before using them.

- When using a DC power supply, you must connect the carbon rod to the positive pole and the workpiece to the negative pole. This requires careful attention to the working current.

These PATIKIL gouging rods offer good performance for metal cutting tasks. They are a solid choice for professionals and hobbyists needing to prepare metal for welding.

2. Broco Industrial Prime Cut Exothermic Cutting Rods – For Exothermic Cutting Torch Kit

Rating: 8.7/10

When you need to cut through tough materials quickly and efficiently, the Broco Industrial Prime Cut Exothermic Cutting Rods are a game-changer. These industrial-grade rods are designed to work with exothermic cutting torch kits, delivering intense heat for serious jobs.

What We Like:

- Cuts Through Almost Anything: These rods burn super hot and can easily cut through steel, cast iron, aluminum, stainless steel, titanium, and even concrete.

- Fast, Easy Ignition: You can light them up quickly with a 12V battery and striker plate or special RapidFire igniters. They are perfect for cutting, piercing, and gouging.

- Precision & Control: The rods burn evenly, giving you clean cuts with less waste. This is a big help for getting metal ready for welding.

- Flexible & Versatile: You can bend these rods to reach tricky spots. They are great for jobs in construction, demolition, and industrial settings.

- Safe & Reliable Performance: They have a built-in safety feature to stop them from burning back into the torch. This makes them a safe choice for metal fabrication and welding.

What Could Be Improved:

- Availability: While not a major issue for most, finding these specific rods might require a bit more searching than common consumables.

- Learning Curve: For those completely new to exothermic cutting, there might be a slight learning curve to master the best techniques for different materials.

These Broco Prime-Cut rods are a powerful and dependable tool for demanding cutting tasks. They offer impressive performance and safety features for professionals.

3. Copper Coated Gouging Carbon Rods

Rating: 9.0/10

Tackle tough metal jobs with ease using these Copper Coated Gouging Carbon Rods. This 10-piece set gives you the tools you need for cutting and shaping metal. They work on many different kinds of metal, making them super useful.

What We Like:

- These rods work on lots of different metals.

- They are built tough. The graphite is good quality, and the copper coating makes them last longer.

- The copper coating helps them cut and gouge metal really well. This makes your work faster and easier.

- They are a good size to hold. At about 14 inches long and a little less than half an inch wide, they are easy to control.

- You can use them for many jobs. They are good for building, making things, and fixing cars.

What Could Be Improved:

- For very thick metal, you might need more power.

- They can get hot, so be careful when using them.

These rods are a solid choice for anyone who works with metal regularly. They offer a good balance of performance and value for your projects.

4. HARFINGTON 10pcs Copper Coated Gouging Carbon 4x355mm Carbon Gouging Rods Electrodes for Cutting and Gouging Metals

Rating: 8.5/10

The HARFINGTON 10pcs Copper Coated Gouging Carbon Rods are a solid choice for anyone needing to cut and shape metal. These rods are made from a special mix of carbon and graphite. They are designed to work well with air carbon gouging tools. This means they help you efficiently remove metal. Their copper coating helps them conduct electricity better, which makes them run cooler. This is great for longer jobs. They can handle many kinds of metal, like steel, copper, and aluminum.

What We Like:

- Good electrical conductivity thanks to the copper coating.

- They are not easily broken, making them last longer.

- They work on a variety of metals for many different jobs.

- The size (4x355mm) is suitable for most standard gouging tools.

What Could Be Improved:

- The description could be clearer about specific applications within foundries or shipbuilding.

- More information on the exact blend of carbon and graphite could be helpful for experts.

These gouging rods offer reliable performance for metalworking tasks. They are a dependable option for both DIYers and professionals.

5. PATIKIL 20pcs 6mmx305mm(1/4″x12″) Carbon Arc Air Gouging Rods Copper Graphite Coated Gouging Electrode Rods for Welding

Rating: 9.4/10

The PATIKIL 20pcs 6mmx305mm Carbon Arc Air Gouging Rods are a solid choice for anyone needing to cut metal. These rods are made from a mix of copper and graphite, which helps them resist high heat and conduct electricity well. They’re designed to be used with a carbon arc gouging process, which is a way to cut metal using an electric arc and compressed air. This makes them useful for shaping metal for welding projects.

What We Like:

- The rods are made with copper and graphite for good heat resistance and electrical conductivity.

- They are not easily broken, which means they last longer.

- They operate with low noise, making the work environment more pleasant.

- The size, 6mm by 305mm, is a common and useful size for many tasks.

- You get a pack of 20 rods, so you have plenty to work with.

What Could Be Improved:

- The instructions mention keeping the rods dry, which can be a minor inconvenience if you’re working in a humid area.

- The note about connecting the carbon rod to the positive pole of the DC power supply requires a bit of electrical knowledge to follow correctly.

These gouging rods are a reliable consumable for metal cutting jobs. They’re built to handle tough work in industries like shipbuilding and bridge construction, helping you get the precise shapes you need for strong welds.

Choosing the Right Cutting Rods for Your Stick Welder

If you’re a DIY enthusiast or a professional welder, you know that the right tools make all the difference. When it comes to stick welding, cutting rods are essential for a variety of tasks, from removing old welds to cutting through metal. But with so many options available, how do you pick the best ones? This guide will help you understand what to look for and make an informed decision.

What are Cutting Rods?

Cutting rods, also known as oxy-fuel cutting rods or carbon-arc gouging rods, are used with a special torch and compressed air or oxygen to cut and shape metal. They are not the same as welding electrodes. They burn at a high temperature and, when combined with a stream of air or oxygen, they blow away molten metal. This process effectively cuts or removes metal.

Key Features to Look For

When you’re shopping for cutting rods, keep these important features in mind:

- Diameter: Rods come in different diameters. A larger diameter rod generally cuts thicker metal faster. Common sizes include 1/4 inch, 3/8 inch, and 1/2 inch.

- Length: Longer rods mean fewer changes during a long job. Standard lengths are usually around 12 inches.

- Core Type: Some rods have a hollow core that allows for a continuous flow of air or oxygen. This makes the cutting process more efficient.

- Packaging: Rods are often sold in boxes of 50 or 100. Consider how many you’ll need for your projects.

Important Materials

Cutting rods are typically made from a carbon core. This carbon burns at a very high temperature.

- Carbon: High-quality carbon is crucial for consistent burning and effective metal removal.

- Coating: Some rods have a special coating. This coating can help stabilize the arc, reduce spatter, and improve the cutting performance.

Factors That Improve or Reduce Quality

Several things affect how well cutting rods perform.

Factors That Improve Quality:

- Consistent Diameter: Rods with a uniform diameter burn more evenly. This leads to cleaner cuts and less effort for you.

- High-Purity Carbon: Pure carbon burns hotter and more consistently. This makes cutting easier and faster.

- Quality Coating: A good coating helps the rod burn smoothly. It also protects the carbon core and can make the cutting process safer.

- Proper Storage: Keep rods dry. Moisture can make them difficult to use and reduce their effectiveness.

Factors That Reduce Quality:

- Inconsistent Diameter: Rods that vary in thickness can cause sputtering and uneven cutting.

- Low-Quality Carbon: Impurities in the carbon can lead to a less stable burn.

- Damaged Coating: A chipped or worn coating means the rod won’t perform as well.

- Exposure to Moisture: Damp rods are hard to ignite and burn poorly.

User Experience and Use Cases

Using cutting rods with a stick welder is straightforward once you get the hang of it. You’ll need a special cutting torch attachment for your welder and a source of compressed air or oxygen.

Common Use Cases:

- Removing Old Welds: Cutting rods are excellent for quickly removing unwanted welds.

- Cutting Through Metal: They can cut through various metals, including steel, iron, and cast iron.

- Gouging: This is the process of creating a groove in metal. It’s useful for preparing surfaces for new welds or removing defects.

- Scrap Metal Preparation: If you have large metal items to scrap, cutting rods can help you break them down into smaller, manageable pieces.

The user experience is generally positive when you have the right rods. You’ll find that good quality rods make the job quicker and require less physical effort. Poor quality rods can be frustrating. They might sputter, not burn consistently, or require you to work harder to achieve the desired cut. Always follow safety precautions, including wearing appropriate personal protective equipment (PPE) like a welding helmet, gloves, and protective clothing.

Frequently Asked Questions (FAQ)

Q: Are cutting rods the same as welding rods?

A: No, cutting rods are different. They are used for cutting and removing metal, not for joining metal like welding rods.

Q: What kind of equipment do I need to use cutting rods?

A: You need a stick welder, a special cutting torch attachment, and a source of compressed air or oxygen.

Q: Can I use cutting rods on any type of metal?

A: Cutting rods work best on ferrous metals like steel, iron, and cast iron. They are not ideal for aluminum or stainless steel.

Q: How do I store cutting rods?

A: Store cutting rods in a dry place. Keep the box sealed to prevent moisture from getting in.

Q: What is the most common diameter for cutting rods?

A: Common diameters include 1/4 inch, 3/8 inch, and 1/2 inch. Thicker rods cut thicker metal.

Q: How does the hollow core help?

A: The hollow core allows air or oxygen to flow through it. This makes the cutting process more efficient and effective.

Q: How do I know if a cutting rod is good quality?

A: Good quality rods have a consistent diameter, pure carbon, and a good coating. They burn smoothly and cut cleanly.

Q: Can I cut thick metal with small diameter rods?

A: You can, but it will be much slower and more difficult. Larger diameter rods are better for thicker materials.

Q: Are cutting rods dangerous to use?

A: Like any welding process, cutting rods involve high heat and sparks. Always use proper safety gear and follow safety guidelines.

Q: Where can I buy cutting rods?

A: You can buy cutting rods at welding supply stores, hardware stores, and online retailers.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.