Are you curious about the deposition rate in welding and how to calculate it? You’ve come to the right place. Understanding deposition rate is essential for welders as it directly affects productivity and overall efficiency. Deposition rate refers to the amount of metal that can be deposited per hour of welding. By accurately calculating the deposition rate, welders can estimate the time needed to complete a welding task and determine the required wire, filler, or electrode.

Photo by weldinghandbook

In this article, we will delve into the concept of deposition rate, explain why it is important, and provide a step-by-step guide on how to calculate it. Whether you are a beginner or an experienced welder, mastering deposition rate will help you enhance your welding skills and optimize your work process.

Importance of Deposition Rate

Deposition rate refers to the amount of filler metal that is deposited onto the base metal during the welding process. It is an essential factor to consider when determining welding efficiency and productivity. By calculating the deposition rate, you can accurately estimate the amount of filler metal required for a particular welding job and optimize your welding processes.

Factors Affecting Deposition Rate in Welding

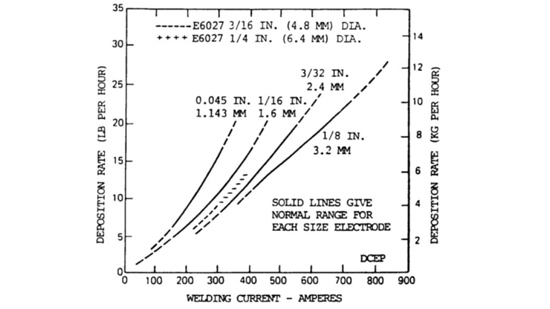

Several factors can influence the deposition rate in welding. These include welding current, welding speed, electrode diameter, and electrode efficiency. Let’s take a closer look at each of these factors and understand their impact on deposition rate.

Welding current plays a crucial role in determining the amount of filler metal deposited. Higher welding currents generally result in higher deposition rates, while lower currents lead to lower deposition rates. It is important to find the right balance to achieve the desired deposition rate for your specific welding project.

Welding speed is another significant factor that affects deposition rate. Faster welding speeds can result in lower deposition rates, as the filler metal has less time to be deposited onto the base metal. On the other hand, slower welding speeds can lead to higher deposition rates. Finding the optimal welding speed is essential for achieving the desired deposition rate.

The diameter of the electrode also plays a role in deposition rate. Larger electrode diameters result in higher deposition rates, while smaller diameters lead to lower deposition rates. It is important to choose the appropriate electrode diameter based on the desired deposition rate and the welding project requirements.

Electrode efficiency refers to the percentage of filler metal that is effectively used in the welding process. Factors such as electrode composition, quality, and handling can impact electrode efficiency. Higher electrode efficiency can contribute to higher deposition rates, while lower efficiency can result in lower deposition rates.

Different Methods to Measure Deposition Rate

There are several methods available to measure deposition rate in welding. The choice of method depends on the specific welding process and the accuracy required. Some common methods include weighing the filler metal before and after welding, using deposition rate calculators, and utilizing specialized measuring devices.

Each method has its advantages and limitations, and it is crucial to choose the most appropriate method for accurate measurement.

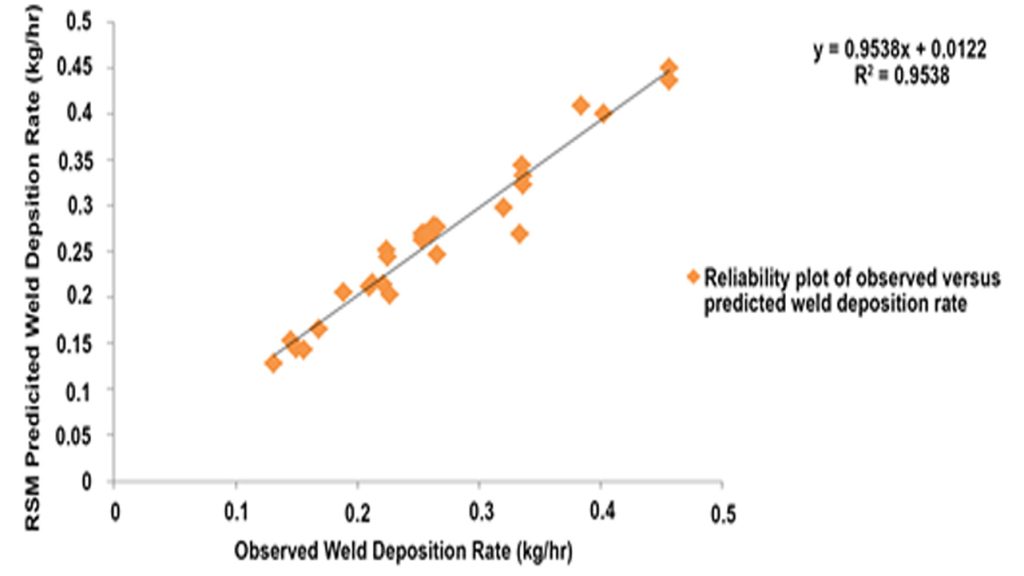

Image by researchgate

Calculation of Deposition Rate in Welding

Calculating the deposition rate involves a series of steps that take into account the factors mentioned earlier. The formula for calculating deposition rate is:

Deposition Rate = (Weight of Filler Metal Deposited / Time)

To accurately calculate the deposition rate, you need to measure the weight of the filler metal before and after welding and record the time taken for the welding process. By dividing the weight of the filler metal deposited by the time, you can determine the deposition rate.

Accurate Deposition Rate Calculations

Accurate deposition rate calculations are crucial for several reasons. Firstly, they help in estimating the amount of filler metal required for a specific welding job. This ensures that you have sufficient filler metal on hand and minimizes material waste. Secondly, accurate deposition rate calculations contribute to achieving high-quality welds by ensuring the right amount of filler metal is deposited onto the base metal. Finally, accurate deposition rate calculations optimize welding processes, leading to improved efficiency and productivity.

Tips to Increase Deposition Rate in Welding

Increasing deposition rate can be beneficial in certain welding projects where higher productivity is desired. Here are some tips to help you increase deposition rate:

Adjust welding current

Increasing the welding current within safe limits can result in higher deposition rates. However, it is important to consider the impact on other welding parameters and ensure the weld quality is not compromised.

Optimize welding speed

Adjusting the welding speed can also affect deposition rate. In some cases, increasing the welding speed can lead to higher deposition rates, while in others, slowing down the speed may be more effective. Experimentation and finding the right balance is key.

Choose the right electrode diameter

Selecting a larger electrode diameter can increase deposition rates. However, it is important to consider the welding project requirements and the welding equipment’s capabilities.

Use high-efficiency electrodes

Choosing electrodes with high efficiency can maximize the amount of filler metal effectively used in the welding process, resulting in higher deposition rates.

Image by scirp

Challenges in Achieving Desired Deposition Rate

While calculating and achieving the desired deposition rate is essential, it is not always a straightforward process. Several challenges can arise, including:

Welding parameter limitations

Certain welding machines or processes may have limitations on the range of welding currents, speeds, or electrode diameters, making it challenging to achieve specific deposition rates.

Welding position and joint configuration

The position and configuration of the weld joint can impact deposition rate. Vertical or overhead positions may require adjustments in welding parameters to achieve the desired deposition rate.

Base metal characteristics

The type and properties of the base metal can affect deposition rate. Materials with high heat conductivity or low melting points may require specific welding techniques or filler metals to achieve the desired deposition rate.

Deposition Rate in Different Welding Processes

Deposition rate can vary depending on the welding process used. Different welding processes, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW), have their own deposition rate characteristics. Understanding the deposition rate for each welding process is crucial for selecting the appropriate process for your specific welding project.

Conclusion

Understanding deposition rate is vital for achieving high-quality welds and maximizing efficiency in welding projects. By accurately calculating the deposition rate and considering factors such as welding current, welding speed, electrode diameter, and electrode efficiency, welders can optimize their processes and achieve the desired results.

Remember to choose the most suitable method for measuring deposition rate and be aware of the challenges that may arise. With the knowledge gained from this article, you are now equipped to excel in your welding projects and deliver exceptional results. Happy welding!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.