A diamond cutoff disc is an indispensable tool for anyone tackling demanding cutting tasks across various materials. Unlike traditional abrasive wheels, these discs feature industrial diamonds embedded in their edges, providing unparalleled durability and cutting efficiency. Whether you’re a professional contractor or a dedicated DIY enthusiast, choosing the right diamond cutting wheel can significantly impact the speed, precision, and overall quality of your work. From slicing through tough metals and rebar to making clean cuts in delicate porcelain and granite, these specialized discs are engineered to withstand extreme conditions and deliver superior performance. Our comprehensive guide delves into the top models, helping you find the perfect diamond cutoff disc to power through your toughest projects with ease.

Quick Product Comparison

Our Top 5 Diamond Cutoff Disc Reviews – Expert Tested & Recommended

1. FOXBC 4-1/2 Inch Diamond Cutoff Disc for Angle Grinder, Metal Cutting, 7/8″ Arbor, 3-Pack

The FOXBC 4-1/2 Inch Diamond Cutoff Disc is an outstanding choice for serious metalworking, offering superior performance and longevity. These diamond-rimmed wheels are designed to outlast standard bonded cut-off discs by up to 100 times, providing incredible value and consistent results for various challenging applications.

Key Features That Stand Out

- ✓ Up to 100X longer cutting life compared to standard bonded discs.

- ✓ Ideal for dry cutting a wide range of metals including rebar, angle iron, cast iron, and stainless steel.

- ✓ Features an advanced Electro-Plating Process for even distribution of diamond abrasive.

- ✓ Ensures better control and precision cutting, minimizing material waste.

- ✓ Comes in a convenient 3-pack, providing excellent value for frequent users.

Why We Recommend It

We recommend the FOXBC Diamond Cutoff Disc for its exceptional durability and versatility in metal cutting. Its ability to handle diverse metals with precision makes it a reliable tool for both professionals and demanding DIYers seeking efficiency and a reduced need for frequent disc changes.

Best For

This disc is best for professionals and serious DIYers who frequently cut various types of metal, rebar, and steel with an angle grinder, prioritizing longevity and precise cuts.

Pros and Cons

Pros:

- Significantly extended lifespan saves time and money.

- Versatile for cutting multiple metal types without changing discs.

- Electro-plated diamonds ensure consistent, precise cuts.

- Durable construction provides reliability for heavy-duty tasks.

Cons:

- Initial cost might be higher than traditional abrasive discs.

- May not be suitable for extremely delicate materials not listed.

Customer Reviews

Customer Review: “I used to go through so many abrasive discs cutting rebar. These FOXBC diamond discs are a game-changer. They cut so much faster and last incredibly long. Highly recommend!”

Customer Review: “Fantastic value in a 3-pack. I’ve been cutting stainless steel and iron without any issues. The cuts are clean, and the disc shows very little wear.”

2. 4.5 Inch Diamond Cutoff Disc for Porcelain, Ceramic, Marble, Granite, 5/8-11 Thread.

This 4.5 Inch Diamond Cutoff Disc is specifically engineered for precision cutting of natural and artificial stone materials. Featuring a robust 5/8″-11 thread, it’s designed for angle grinders, providing efficient and smooth operation for tasks involving porcelain, ceramic, marble, and granite.

Key Features That Stand Out

- ✓ Optimal 4.5-inch diameter with a 5/8″-11 thread for angle grinders.

- ✓ Double-sided Hexagon Design with 25mm diamond height on both faces for superior performance.

- ✓ Features 1.7mm diamond thickness and #60/70 grit for fast, smooth, and chip-free cutting.

- ✓ Ideal for cutting, shaping, grinding, and creating grooves in hard materials.

- ✓ Ensures a professional finish on delicate and expensive stone surfaces.

Why We Recommend It

We highly recommend this diamond cutting wheel for its specialized design that ensures clean, precise cuts on brittle materials. Its double-sided diamond coating and specific grit size minimize chipping, making it indispensable for tile and stone work where finish quality is paramount.

Best For

This disc is best for tile installers, stonemasons, and DIYers working on bathroom or kitchen remodels requiring precise, chip-free cuts in porcelain, ceramic, marble, granite, and artificial stone.

Pros and Cons

Pros:

- Excellent for chip-free cutting of hard and brittle materials.

- Double-sided design increases cutting efficiency and lifespan.

- Specific grit (#60/70) optimized for stone and tile.

- Durable construction ensures reliable performance over time.

Cons:

- Primarily designed for stone/tile, less suitable for metal.

- 5/8″-11 thread requires compatible angle grinders.

Customer Reviews

Customer Review: “Good seller, product, price, and delivery. Cut title like cheese cake. A*****”

Customer Review: “This tile grinder wheel appears to be good. I haven’t started my tile project yet. this wheel has great reviews.”

3. EZARC 4 1/2 Inch Diamond Cutoff Disc for Cutting Metal, Rebar, and Steel

The EZARC 4 1/2 Inch Diamond Cutoff Disc is a highly cost-effective solution for cutting various metals, delivering exceptional longevity and safety. Utilizing advanced diamond technology, this disc is engineered to perform over 5,000 cuts, significantly reducing replacement costs compared to traditional bonded discs.

Key Features That Stand Out

- ✓ Diamond Technology offers 5,000+ cuts, equating to over 100 standard bonded cut-off wheels.

- ✓ Versatile for dry cutting metal, rebar, iron, alloy steel, aluminum, and various pipes/sheet metal.

- ✓ Solid steel wheel body greatly reduces the risk of shatter and injury, enhancing user safety.

- ✓ Provides a full metal cutting solution in one durable disc.

- ✓ Features abrasive grit on either side for shaping capabilities beyond just cutting.

Why We Recommend It

We recommend the EZARC diamond cutoff disc for its impressive durability, safety features, and incredible cost-effectiveness. It’s a fantastic budget-friendly option that doesn’t compromise on performance, offering consistent cutting power and a long lifespan for various metal applications.

Best For

This disc is best for budget-conscious professionals and DIYers who require a durable and safe metal cutting solution for general metal fabrication, rebar cutting, and automotive repair tasks.

Pros and Cons

Pros:

- Extremely long life, vastly outperforming abrasive discs.

- Enhanced safety due to solid steel body, preventing shattering.

- Versatile for a wide range of metal cutting tasks.

- Low dust generation compared to abrasive wheels.

Cons:

- Might require a slightly slower feed rate on very thick materials.

- Initial bite on some softer metals can be aggressive.

Customer Reviews

Customer Review: “Using this cutting wheel on the DeWalt DCG418 is a distinct pleasure. It cuts stupidly quick, cleanly and lasts a long time. Added bonus is the grit on either side of the disc about 0.125″ down from the proper cutting edge that allows for some versatility in shaping sheet metal that a composite d”

Customer Review: “Cuts through metal like butter. I was hard on the disk and it did not warp or show signs of wear, safe disk for home use. Low dust for a decent price.”

4. Diamond Cutoff Disc, 4.5-inch for Angle Grinder, Cuts Rebar, Steel, Iron, 7/8″ Arbor

This 4.5-inch diamond cutoff disc is engineered for powerful and versatile metal cutting applications. Designed to fit standard angle grinders with a 7/8″ arbor, it offers impressive longevity and consistent performance across tough materials like rebar, steel, and iron, making it a reliable addition to any toolkit.

Key Features That Stand Out

- ✓ Versatile cutting capability for various metal applications including rebar, steel, and iron.

- ✓ Promises long-lasting performance with over 5000 cuts, maintaining consistent quality.

- ✓ Features a common 7/8 inch arbor size for secure mounting on most standard angle grinders.

- ✓ Reduces dust and sparks significantly compared to abrasive wheels, enhancing safety.

- ✓ Maintains a cool cutting temperature, minimizing material distortion.

Why We Recommend It

We recommend this diamond cutting disc for its excellent balance of versatility and durability in metal cutting. Its high cut count and consistent performance ensure efficiency, while the standard arbor size makes it a convenient choice for most angle grinder users.

Best For

This disc is best for construction workers, fabricators, and serious DIYers needing a durable and efficient solution for cutting various metals, especially rebar and structural steel, with a standard angle grinder.

Pros and Cons

Pros:

- Exceptional longevity reduces downtime and replacement costs.

- Versatile for a wide array of metal cutting tasks.

- Standard arbor fits most angle grinders readily.

- Produces less dust and sparks, improving workplace safety and visibility.

Cons:

- May not be ideal for ultra-fine finish work on softer metals.

- Can be slightly slower on certain exotic alloys than specialized discs.

Customer Reviews

Customer Review: “I recently picked up the JTEX Diamond Cut Off Wheel and it’s been a great addition to my tool kit. Installing it on my angle grinder was quick and easy. It fit perfectly without any wobble and was ready to go in seconds. I didn’t need any special tools or adjustments, which made the whole process sm”

Customer Review: “Really like this set of wheels for cutting high carbon steel. You don’t get the dust that is a product of cutting with the abrasive wheels.These are rated for 13280 RPM, which is a big confidence boost for me as I am always concerned when your grinder’s RPM is close to the disc rating. If you have e”

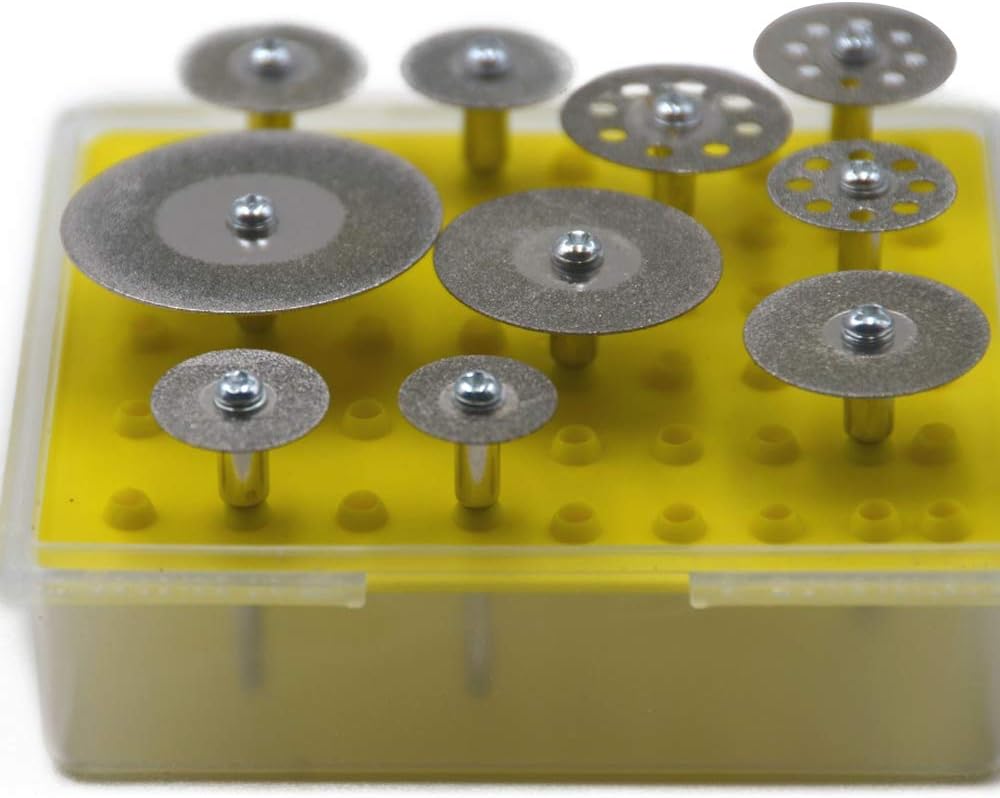

5. Diamond Cutting Wheel, 10PCS 1/8″ Diamond Cutting Discs Cut-Off Wheel Blades Set Comepatible with…

This set of 10PCS 1/8″ Diamond Cutting Wheels transforms your rotary tool into a powerful micro-cutting and grinding machine. Each steel wheel is permanently brazed with 200-grit industrial diamonds, making them suitable for intricate work on glass, tile, stone, and even hardened steel where precision is key.

Key Features That Stand Out

- ✓ Designed for use with Dremel, Wen, and other rotary tools for small-scale, detailed work.

- ✓ Features 200-grit industrial diamonds permanently brazed to the steel surface for superior cutting.

- ✓ Ideal for cutting and grinding incredibly hard materials like glass, tile, stone, and hardened steel.

- ✓ Comes as a convenient 10-piece set, offering excellent value and multiple replacements.

- ✓ Enables high-speed cut-off and grinding for intricate and delicate projects.

Why We Recommend It

We recommend this diamond cutting wheel set for its specialized application in fine, detailed work that larger angle grinders cannot handle. The multiple discs in the pack offer great value for hobbyists and jewelers who work with small, hard materials requiring high precision.

Best For

This set is best for hobbyists, jewelers, model makers, and craftsmen who need to perform intricate cuts and grinding on small pieces of hard materials such as glass, ceramics, precious stones, and hardened metals using a rotary tool.

Pros and Cons

Pros:

- Excellent for precision work on small, hard materials.

- Highly effective on glass, tile, stone, and hardened steel.

- Cost-effective with 10 discs included in the set.

- Compatible with popular rotary tools like Dremel.

Cons:

- Not suitable for large-scale cutting tasks.

- Requires a rotary tool, not compatible with angle grinders.

- Relatively small diameter limits depth of cut.

Customer Reviews

Customer Review: “It arrives in good condition and just like in the photo”

Customer Review: “Even though these were not expensive I am very pleased with them. I’ve been using them to carve rocks and as long as I keep them cool they are great”

Complete Buying Guide for Diamond Cutoff Disc

Essential Factors We Consider

When selecting the best diamond cutoff disc, several critical factors come into play to ensure you get the right tool for your specific needs. First and foremost, consider the material you’ll be cutting. Discs are specialized for metal, tile, concrete, stone, or even multi-purpose use. Each material requires a different bond hardness, diamond concentration, and segment design for optimal performance and longevity. For instance, a soft-bonded disc works best on hard materials like granite, allowing diamonds to release easily for fresh cutting edges, while a hard-bonded disc is ideal for softer, abrasive materials like concrete. Secondly, the arbor size and disc diameter must match your cutting tool, whether it’s an angle grinder, circular saw, or tile saw. Common sizes include 4.5-inch for angle grinders and larger diameters for masonry saws. Finally, evaluate the type of cut you need – wet or dry. Many diamond discs are designed for dry cutting, offering convenience, while wet cutting (often with water cooling) provides cleaner cuts, extends disc life, and reduces dust, especially for tile and stone.

Budget Planning

Investing in a high-quality diamond cutoff disc can save you money in the long run, despite a higher initial cost. Consider the “cost per cut” rather than just the purchase price. A premium diamond disc might cost more upfront but will last significantly longer, perform more efficiently, and require fewer replacements than cheaper, less durable alternatives. Look for brands known for their industrial-grade diamonds and robust construction. While a budget-friendly option might suffice for occasional light tasks, consistent use on tough materials warrants a disc designed for professional endurance. Factor in the value of your time and the quality of your finish – a reliable disc will lead to fewer re-dos and greater satisfaction.

Final Thoughts

Choosing the ideal diamond cutoff disc involves understanding your project’s demands, the materials you’re working with, and the capabilities of your tools. By prioritizing disc type, size compatibility, and considering a disc’s overall durability and cutting efficiency, you can make an informed decision that enhances your productivity and the quality of your work. Always prioritize safety by wearing appropriate personal protective equipment (PPE) and following tool manufacturer guidelines. With the right diamond cutting wheel, you’ll tackle challenging cuts with confidence and achieve professional-grade results every time.

Frequently Asked Questions

Q: What is a diamond cutoff disc used for?

A: A diamond cutoff disc is primarily used for cutting very hard, abrasive materials that would quickly wear down or damage traditional abrasive wheels. This includes materials like concrete, asphalt, stone, brick, ceramic tile, porcelain, various metals (rebar, steel), and even glass.

Q: Can I use a diamond cutoff disc for cutting metal?

A: Yes, many diamond cutoff discs are specifically designed for cutting metal, including rebar, steel, iron, and alloy steel. These metal-specific diamond discs offer significantly longer life and faster cutting speeds compared to traditional abrasive metal-cutting wheels, with less dust and sparks.

Q: What’s the difference between wet and dry cutting diamond discs?

A: Dry cutting diamond discs are designed to dissipate heat through air cooling, often featuring segments with gullets or slots. They are convenient for quick cuts without water. Wet cutting diamond discs require water to cool the blade, lubricate the cut, and flush away debris. Wet cutting generally provides cleaner cuts, reduces dust, and extends the blade’s life, especially on very hard or heat-sensitive materials like porcelain or polished stone.

Q: How do I choose the correct size diamond cutoff disc for my tool?

A: The diamond cutoff disc must match the arbor size and maximum diameter specifications of your cutting tool (e.g., angle grinder, circular saw, tile saw). Common angle grinder sizes are 4.5-inch, 5-inch, and 7-inch, with arbor sizes typically 7/8 inch or 5/8-11 thread. Always check your tool’s manual for compatible disc sizes and arbor specifications.

Q: How long do diamond cutoff discs last compared to abrasive discs?

A: Diamond cutoff discs typically last 50 to 100 times longer than traditional abrasive discs. Their diamond segments wear down much slower, providing consistent cutting depth and efficiency throughout their lifespan, making them a more cost-effective choice for frequent and demanding cutting tasks.

Selecting the right diamond cutoff disc is crucial for achieving efficient, precise, and safe cuts across a spectrum of challenging materials. Whether you’re cutting through stubborn rebar, intricate porcelain tiles, or dense granite slabs, the discs reviewed above offer specialized performance and exceptional durability. We encourage you to explore our top recommendations and consider the specific demands of your projects. Click on the “Check Price on Amazon” buttons to find the perfect diamond cutting wheel that empowers you to tackle any job with confidence and superior results!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.