Soldering is a fundamental technique used to join metal components together by melting a filler metal, known as solder, to create a strong and permanent bond. The process involves heating the solder to its melting point and then allowing it to flow into the joint between the two metal pieces. This forms a metallurgical bond, ensuring electrical conductivity or structural integrity, depending on the application. Soldering is commonly used in electronics, plumbing, jewelry making, and various DIY projects.

The key to successful soldering lies in selecting the right type of solder for the job, as different solders have varying compositions and characteristics. Understanding the properties of each type of solder is essential for achieving reliable and durable connections. Factors such as melting point, conductivity, and compatibility with the base metals play a crucial role in determining the suitability of a particular solder for a given application.

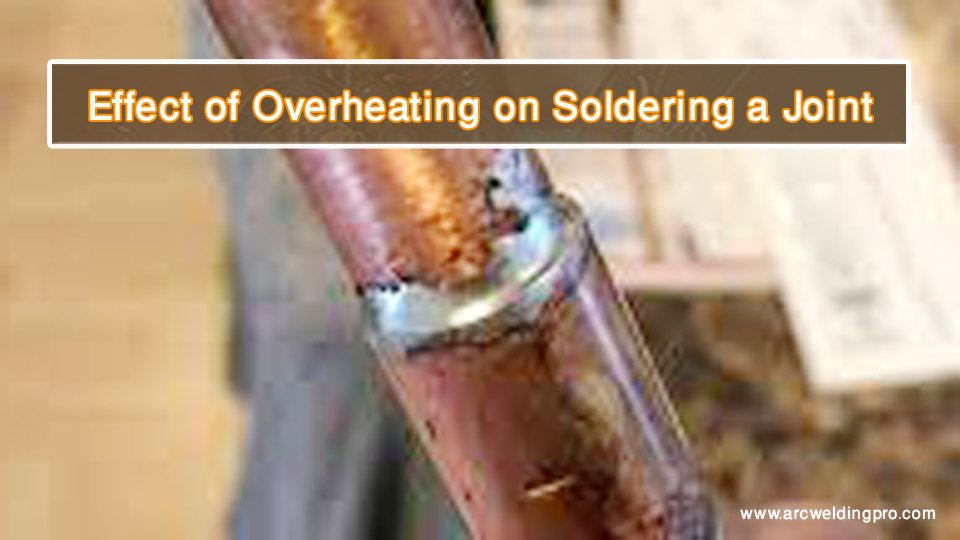

Photo by mosaic-lille

Before delving into the specifics of different types of solder, it is important to familiarize oneself with the basic tools and techniques required for soldering. A soldering iron or soldering station, solder wire, flux, and a clean work surface are essential for carrying out soldering tasks effectively. Proper preparation of the joint, adequate heat control, and the right soldering technique are all critical factors that contribute to successful soldering outcomes.

Lead-based Solder: Its Composition, Uses, and Considerations

Lead-based solder, traditionally composed of a mixture of tin and lead, has long been a popular choice for soldering due to its low melting point, ease of use, and reliable performance. The addition of lead to tin lowers the melting point of the solder, making it easier to work with and ensuring good wetting properties on metal surfaces. Lead-based solder is commonly used in electronics manufacturing, plumbing, and stained glass work.

The use of lead-based solder has raised environmental and health concerns due to the toxic nature of lead. In response to these issues, many countries have imposed restrictions on the use of lead-based solder in certain applications, such as electronics and plumbing. As a result, the industry has shifted towards lead-free solder alternatives, which offer comparable performance while eliminating the risks associated with lead exposure.

When working with lead-based solder, it is important to take precautions to minimize exposure to lead fumes and residues. Proper ventilation, personal protective equipment, and safe handling practices are essential to ensure the health and safety of the soldering operator and others in the vicinity. Despite its drawbacks, lead-based solder remains a viable option for certain applications where its unique properties are necessary.

Lead-free Solder: Advantages, Applications, and Environmental Impact

Lead-free solder has emerged as a safer and more environmentally friendly alternative to traditional lead-based solder. Composed of metals such as tin, silver, copper, and bismuth, lead-free solder offers comparable mechanical and electrical properties to lead-based solder while complying with regulations aimed at reducing the environmental impact of electronic waste. Lead-free solder is widely used in electronics manufacturing, automotive industry, and aerospace applications.

One of the key advantages of lead-free solder is its reduced environmental impact, as it eliminates the risks associated with lead pollution and contamination. By switching to lead-free solder, manufacturers can help mitigate the environmental harm caused by hazardous materials and contribute to sustainable and eco-friendly practices. Additionally, lead-free solder is compatible with modern electronics components and assembly processes, making it a preferred choice for contemporary manufacturing needs.

Despite its benefits, lead-free solder does have some drawbacks compared to lead-based solder. Lead-free solder typically has a higher melting point, which can make the soldering process slightly more challenging and require adjustments to soldering techniques and equipment.

Additionally, lead-free solder may exhibit less thermal conductivity than lead-based solder, impacting heat dissipation in certain applications. However, ongoing research and development efforts are continually improving the performance and usability of lead-free solder materials.

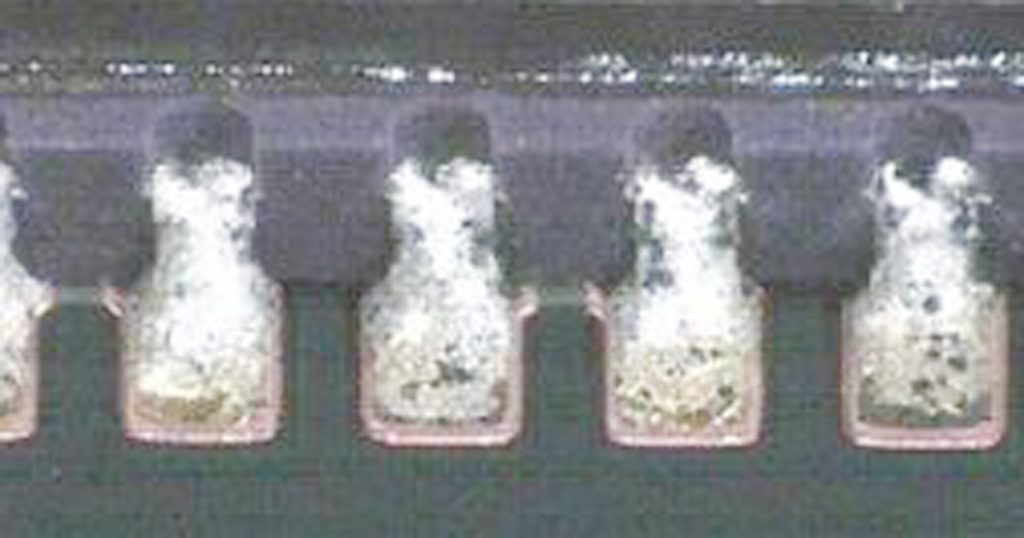

Image by quora

Flux-cored Solder: Benefits, Working Principle, and Applications

Flux-cored solder is a type of solder wire that contains a flux core within its hollow center. Flux is a chemical cleaning agent that helps remove oxidation from the metal surfaces being soldered, ensuring proper wetting and adhesion of the solder. Flux-cored solder eliminates the need for a separate flux application, simplifying the soldering process and improving the quality of solder joints. This type of solder is commonly used in electronics repair, plumbing, and automotive applications.

The flux core in flux-cored solder activates when heated, releasing flux to clean the surfaces and facilitate the soldering process. The flux removes oxides, contaminants, and impurities from the metal, allowing the solder to flow smoothly and bond effectively to the base materials. Flux-cored solder is available in different formulations to suit various soldering tasks, such as rosin-core flux for electronics work and acid-core flux for plumbing applications.

Using flux-cored solder offers several benefits, including improved wetting and flow of solder, reduced risk of cold joints and solder bridges, and enhanced reliability of solder connections. The flux core acts as a protective barrier during soldering, preventing oxidation and ensuring a clean and strong bond between the metal surfaces. Proper flux selection is crucial for achieving high-quality solder joints and preventing issues such as poor adhesion or insufficient wetting.

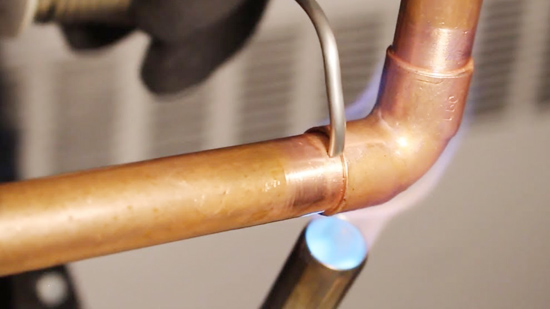

Image by billshorthousemetals

Solder Paste: Its Composition, Uses, and Application Techniques

Solder paste is a mixture of powdered solder alloy and flux suspended in a paste-like medium. It is commonly used in surface mount technology (SMT) and reflow soldering processes to attach electronic components to printed circuit boards (PCBs). Solder paste offers precise control over the amount of solder deposited on the PCB pads, enabling high-density and high-speed assembly of electronic devices. The composition of solder paste plays a critical role in determining the performance and reliability of solder joints.

The flux in solder paste serves multiple purposes, including removing oxides from metal surfaces, promoting wetting of solder, and controlling the reflow process during soldering. The flux activates at specific temperature ranges, ensuring proper cleaning and bonding of the solder to the PCB pads and component leads. Solder paste formulations vary based on the type of solder alloy used, the application method, and the reflow profile required for the assembly process.

Applying solder paste accurately is essential for achieving consistent and reliable solder joints. Techniques such as stencil printing, dispensing, and jetting are commonly used to deposit solder paste onto PCB pads prior to component placement. Proper alignment, solder volume control, and reflow temperature profile optimization are critical factors that influence the quality of solder joints and the overall reliability of electronic assemblies. Advanced solder paste formulations offer enhanced performance and solderability for demanding SMT applications.

Silver Solder: Properties, Applications, and Compatibility Considerations

Silver solder, also known as silver brazing alloy, is a type of solder containing a high percentage of silver along with other metals such as copper, zinc, and cadmium. Silver solder offers superior strength, corrosion resistance, and thermal conductivity compared to standard tin-based solders, making it suitable for high-performance applications in electronics, jewelry making, and plumbing. The melting temperature of silver solder is higher than that of traditional solders, requiring careful control during the soldering process.

One of the key properties of silver solder is its ability to create strong and durable joints that can withstand high temperatures and mechanical stress. Silver solder is commonly used in applications where reliability and longevity are paramount, such as aerospace components, medical devices, and precision instruments. The high silver content in silver solder provides excellent electrical conductivity, making it ideal for soldering electrical connections that require low resistance.

When using silver solder, compatibility with the base metals being joined is a crucial consideration. Silver solder forms intermetallic compounds with many metals, which can affect the mechanical and electrical properties of the joint. Proper surface preparation, flux selection, and soldering technique are essential for achieving reliable and defect-free solder joints when working with silver solder. Additionally, silver solder should be handled with care due to its higher melting point and potential health hazards associated with certain alloying elements.

Soft Solder: Uses, Limitations, and Suitable Applications

Soft solder, also known as tin-based solder, is a low-temperature solder alloy typically composed of tin and other metals such as lead, bismuth, or silver. Soft solder is widely used in electronics assembly, plumbing, and jewelry making due to its relatively low melting point and ease of use. Soft solder forms strong and reliable joints on a variety of metals, providing a cost-effective solution for joining components in a wide range of applications.

One of the primary advantages of soft solder is its low melting temperature, which allows for the soldering of heat-sensitive components without damaging them. Soft solder flows easily and wets the metal surfaces well, creating durable connections that exhibit good electrical conductivity. Soft solder is available in different formulations to suit specific applications, with lead-free options becoming increasingly popular due to environmental regulations.

Image by manomano

Despite its versatility, soft solder does have limitations, particularly in high-temperature or high-stress applications where stronger joints are required. Soft solder joints may be susceptible to mechanical failure under heavy loads or elevated temperatures, limiting their suitability for certain engineering applications.

Understanding the capabilities and limitations of soft solder is essential for choosing the right soldering material for a given project and ensuring the long-term reliability of soldered connections.

Specialized Solders: Exploring Niche Soldering Materials for Specific Applications

In addition to the commonly used solder alloys mentioned above, there are specialized solders designed for specific applications that require unique properties or performance characteristics. These specialized solders are tailored to meet the demands of niche industries such as aerospace, automotive, and medical sectors, where stringent requirements for reliability, performance, and safety must be met. By using specialized solders, manufacturers can achieve superior results in critical applications.

Examples of specialized solders include high-temperature solders for soldering ceramic components, low-temperature solders for heat-sensitive materials, and conductive adhesives for bonding electronic components without traditional soldering. Each type of specialized solder is formulated to address specific challenges and provide optimal performance under specific conditions.

By leveraging the unique properties of specialized solders, engineers and manufacturers can overcome technical obstacles and achieve superior soldering results.

When selecting a specialized solder for a particular application, factors such as compatibility with materials, thermal stability, electrical conductivity, and environmental considerations must be taken into account. Proper training and expertise in handling specialized solders are essential to ensure successful soldering outcomes and adherence to industry standards and regulations.

By exploring the diverse range of specialized solders available, soldering professionals can expand their capabilities and tackle complex soldering challenges with confidence.

Conclusion

The world of solder offers a diverse range of options to suit various soldering needs across industries and applications. Whether you’re working on electronics, plumbing, jewelry, or specialized components, selecting the right type of solder is crucial for achieving strong and reliable connections. By understanding the characteristics, advantages, and limitations of different types of solder, you can make informed decisions that ensure the success of your soldering projects.

From lead-based solder to environmentally friendly alternatives, flux-cored solder, solder paste, silver solder, soft solder, and specialized solders, each type of solder brings unique properties and capabilities to the soldering process.

By considering factors such as melting point, conductivity, compatibility, and environmental impact, you can choose the most suitable solder for your specific project requirements. Whether you prioritize performance, safety, or sustainability, there is a solder type that meets your needs.

By staying informed about the latest developments in soldering materials and techniques, you can enhance your soldering skills and tackle a wide range of projects with confidence. Investing in quality solder and equipment, practicing proper soldering techniques, and following safety guidelines are essential steps towards achieving professional soldering results.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.