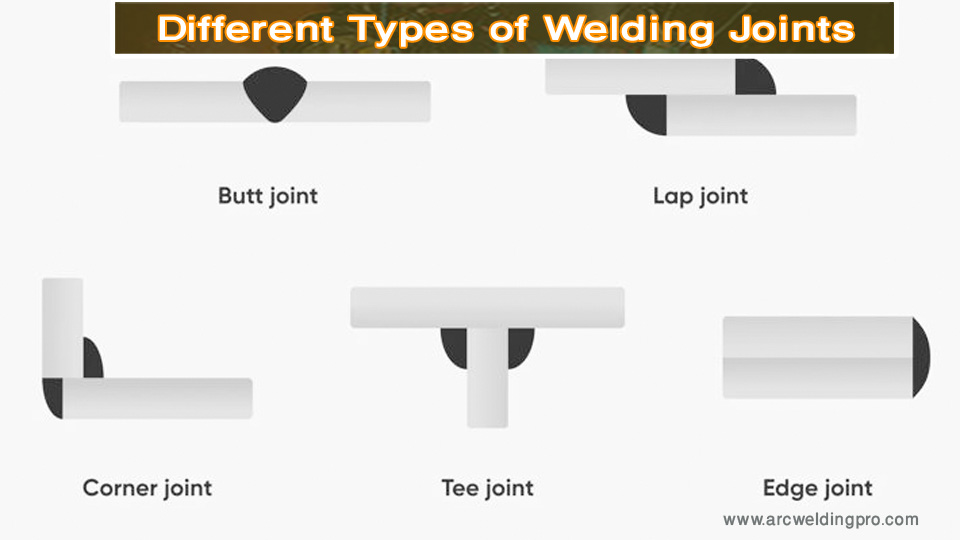

Welding is a crucial process in metal fabrication, construction, and manufacturing industries. The success of any welding project largely depends on the type of joint used and how well it is executed. In this guide, we’ll explore the different types of welding joints, their characteristics, applications, and provide diagrams to help you understand each joint type better.

Understanding Welding Joints

A welding joint is the manner in which two or more metal pieces are brought together for welding. The choice of joint type depends on various factors, including the thickness of the materials, the load the joint will bear, accessibility, and the welding process being used.

Five Basic Types of Welding Joints

According to the American Welding Society (AWS), there are five fundamental types of welding joints:

- Butt Joint

- Tee Joint

- Corner Joint

- Lap Joint

- Edge Joint

Image by fractory

Butt Joint

A butt joint is formed when two pieces of metal are placed edge to edge in the same plane. It’s one of the most common and straightforward joint types used in welding.

Variations of Butt Joint

Butt joints can have several variations based on the edge preparation:

- Square Butt

- Single-V Butt

- Double-V Butt

- Single-U Butt

- Double-U Butt

- Single-J Butt

- Double-J Butt

- Single-Bevel Butt

- Double-Bevel Butt

Applications of Butt Joint

Butt joints are widely used in:

- Pipeline construction

- Structural steel work

- Pressure vessel fabrication

- Shipbuilding

Advantages of Butt Joint

- Can achieve full penetration

- Provides a strong joint when properly executed

- Suitable for a wide range of material thicknesses

Disadvantages of Butt Joint

- Requires precise fit-up

- May need edge preparation for thicker materials

- Can be prone to distortion in thin materials

Tee Joint

A tee joint is formed when two pieces meet at right angles, forming a T-shape. One piece is perpendicular to the other.

Variations of Tee Joint

- Single Fillet Tee

- Double Fillet Tee

- Full Penetration Tee

Applications of Tee Joint

Tee joints are commonly used in:

- Structural steel fabrication

- Shipbuilding

- Automotive frame construction

- HVAC ductwork

Advantages of Tee Joint

- Provides good strength in perpendicular configurations

- Suitable for joining materials of different thicknesses

- Can be welded from one or both sides

Disadvantages of Tee Joint

- May be prone to lamellar tearing in certain materials

- Can create stress concentrations at the joint

Corner Joint

A corner joint is formed by joining two pieces at their edges, usually at a right angle. It can be open (forming an L-shape) or closed.

Variations of Corner Joint

- Closed Corner

- Open Corner

- Half Open Corner

Applications of Corner Joint

Corner joints are frequently used in:

- Sheet metal fabrication

- Box and container construction

- Furniture making

- Architectural metalwork

Advantages of Corner Joint

- Provides a neat finish for visible corners

- Can be strong when properly reinforced

- Suitable for thin materials

Disadvantages of Corner Joint

- May require additional reinforcement for high-stress applications

- Can be challenging to achieve full penetration

Lap Joint

A lap joint is created when two overlapping pieces are welded together. The overlap can be partial or full.

Variations

- Single Lap Joint

- Double Lap Joint

- Offset Lap Joint

Applications of Lap Joint

Lap joints are commonly used in:

- Automotive body work

- Sheet metal fabrication

- Aerospace industry

- Overlapping plates in tank construction

Advantages of Lap Joint

- Easy to set up and weld

- Good for joining dissimilar thicknesses

- Can provide high joint strength in shear loading

Disadvantages of Lap Joint

- Potential for crevice corrosion in the overlap area

- May create stress concentrations

- Not suitable for applications with tensile loading perpendicular to the joint

Edge Joint

An edge joint is formed when the edges of two or more parallel pieces are welded together. The pieces may be in the same plane or bent at an angle.

Variations of Edge Joint

- Plain Edge Joint

- Flanged Edge Joint

Applications of Edge Joint

Edge joints are used in:

- Sheet metal work

- Joining thin plates

- Sealing edges of tanks or containers

- Decorative metalwork

Advantages of Edge Joint

- Economical for thin materials

- Provides a neat appearance

- Suitable for low-stress applications

Disadvantages of Edge Joint

- Limited strength compared to other joint types

- Not suitable for thick materials or high-stress applications

- Can be prone to burn-through on very thin materials

Comparison of Welding Joint Types

To better understand the characteristics and applications of different welding joints, let’s compare them in a table:

| Joint Type | Strength | Complexity | Material Thickness Range | Common Applications |

|---|---|---|---|---|

| Butt Joint | High | Medium to High | Thin to Thick | Pipelines, Pressure Vessels |

| Tee Joint | Medium to High | Medium | Thin to Thick | Structural Steel, Shipbuilding |

| Corner Joint | Medium | Low to Medium | Thin to Medium | Sheet Metal, Boxes |

| Lap Joint | Medium | Low | Thin to Medium | Automotive, Aerospace |

| Edge Joint | Low to Medium | Low | Thin | Sheet Metal, Tanks |

Factors Influencing Joint Selection

When choosing a welding joint type, consider the following factors:

- Material thickness

- Load requirements

- Accessibility for welding

- Cost and time constraints

- Aesthetic requirements

- Welding process being used

- Environmental conditions

- Regulatory requirements

Best Practices for Welding Joints

To ensure high-quality welds, follow these best practices:

- Proper joint preparation: Clean surfaces and prepare edges as required.

- Correct fit-up: Ensure proper alignment and gap before welding.

- Appropriate welding parameters: Use the correct current, voltage, and travel speed.

- Proper technique: Maintain consistent travel speed and electrode angle.

- Adequate heat input: Balance heat input to avoid distortion and ensure proper penetration.

- Post-weld treatment: Perform any necessary heat treatment or finishing.

- Quality control: Implement thorough inspection and testing procedures.

Common Welding Joint Defects and Solutions

Butt Joint Defects

- Lack of penetration Solution: Adjust welding parameters, use proper edge preparation

- Porosity Solution: Clean materials thoroughly, check shielding gas coverage

- Undercutting Solution: Adjust travel speed and electrode angle

Tee Joint Defects

- Lamellar tearing Solution: Use low-hydrogen electrodes, preheat materials

- Incomplete fusion Solution: Adjust welding angle, increase heat input

Corner Joint Defects

- Burn-through Solution: Reduce heat input, use backing material if necessary

- Distortion Solution: Use proper clamping, apply intermittent welding technique

Lap Joint Defects

- Crevice corrosion Solution: Seal edges completely, consider alternative joint design

- Incomplete fusion at overlap Solution: Ensure proper fit-up, adjust welding parameters

Edge Joint Defects

- Burn-through on thin materials Solution: Reduce heat input, use pulsed welding technique

- Lack of reinforcement Solution: Add filler material, adjust welding parameters

Image by reddit

Innovations in Welding Joint Design

As technology advances, new innovations in welding joint design are emerging:

- Hybrid joints: Combining different joint types for optimal performance

- Friction stir welding: Creating joints without melting the base material

- Laser welding: Enabling precise, high-speed welding of complex joints

- Adaptive welding systems: Using sensors and AI to optimize joint parameters in real-time

Conclusion

Different types of welding joints and their characteristics is crucial for any welding professional or enthusiast. Each joint type has its own strengths and limitations, and the choice of joint can significantly impact the quality, strength, and performance of the welded structure.

By considering factors such as material properties, load requirements, and application-specific needs, you can select the most appropriate joint type for your project. Proper preparation, execution, and quality control are key to achieving strong, durable welds regardless of the joint type chosen.

As welding technology continues to evolve, staying informed about new joint designs and welding techniques will help you tackle increasingly complex fabrication challenges and produce high-quality welds in a wide range of applications.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.