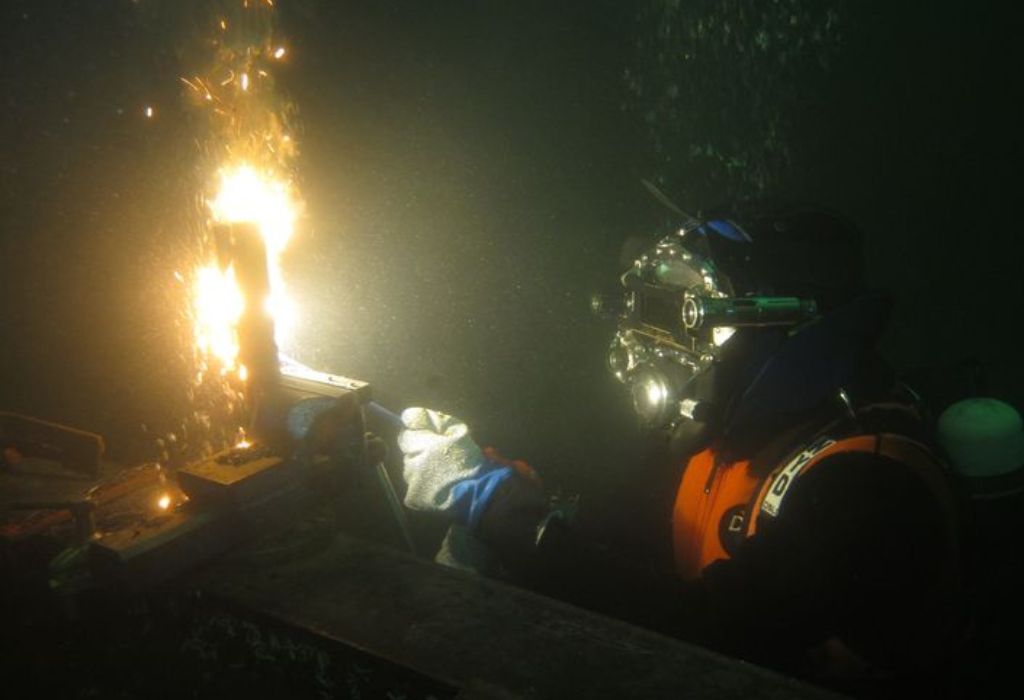

A thick fog settles over the ocean as a diver descends into the dark depths, torch in hand.

Below the surface, visibility fades, pressure builds, and a faint hum of electricity echoes through the water.

This is the world of the underwater welder — where skill meets risk in one of the most dangerous professions on Earth.

Many have heard the rumors: underwater welding shortens your life. But is that really true? Does working in such an extreme environment truly reduce a welder’s lifespan, or are these fears exaggerated?

The truth lies somewhere between myth and measurable danger — and it deserves a closer look.

Underwater welders operate in conditions where the smallest mistake can be fatal. According to the Occupational Safety and Health Administration (OSHA), the underwater welding industry has a fatality rate exceeding 15%, making it several times more hazardous than most industrial jobs (OSHA).

The combination of electric current, pressurized gases, and extreme underwater conditions creates a deadly trifecta of risk.

Yet, despite these dangers, thousands continue to pursue this career every year — drawn by high pay, adventure, and the prestige of mastering one of the world’s toughest trades.

The question then becomes: what toll does it take on the human body and life expectancy?

This guide dives deep into the facts behind the fear. You’ll discover what causes health issues in underwater welders, how modern safety standards are improving survival rates, and whether it’s truly fair to say the job “shortens your life.

What Is Underwater Welding?

Underwater welding, also known as hyperbaric welding, is a specialized process where skilled divers perform welding tasks below the surface of the water. It combines two demanding professions — commercial diving and welding — into one high-risk, high-reward trade.

This type of work is critical for maintaining offshore oil rigs, pipelines, ship hulls, dams, and underwater structures. When metal surfaces corrode or crack underwater, welders are called in to perform precision repairs that keep vital infrastructure safe and operational.

There are two main types of underwater welding — wet welding and dry (hyperbaric) welding. In wet welding, the diver works directly in the water while wearing specialized diving gear and using waterproof electrodes. The electric arc burns in the water itself, creating intense heat that fuses the metal. In dry welding, a pressurized chamber (called a habitat) is sealed around the welding area, keeping it dry while maintaining underwater pressure. This method offers better control and reduces the risk of electric shock but is more complex and costly.

Underwater welders must also be trained in decompression techniques, gas management, and emergency procedures, since both water pressure and electrical currents pose life-threatening dangers. Only certified commercial divers with additional welding qualifications are allowed to perform these operations.

Despite the complexity, the job remains vital for industries that depend on underwater maintenance. Each dive involves precise timing, communication with surface crews, and continuous monitoring of environmental factors like depth, temperature, and visibility — all while maintaining stable weld quality.

What is hyperbaric welding?

It’s a dry welding method performed in a sealed pressurized chamber to protect the work area from water.

How deep do underwater welders usually work?

Most commercial projects range from 30 to 300 feet, but some deep-sea operations exceed 1,000 feet.

Which industries use underwater welding the most?

Offshore oil, marine construction, ship repair, and energy infrastructure.

Why is underwater welding so challenging?

Because welders must manage high pressure, limited visibility, and electrical hazards simultaneously.

The Fatal Risks of Underwater Welding

Underwater welding is often labeled as one of the world’s most dangerous jobs — and for good reason. The combination of electricity, water, and human exposure creates a life-threatening environment that leaves no room for error.

The primary risks include electric shock, explosions, drowning, and decompression sickness — each capable of killing a diver instantly if mishandled. The fatality rate in this profession has been estimated between 10–15%, which is among the highest of all skilled trades (Commercial Diving Academy).

Electric shock remains the biggest threat. Even a minor insulation failure can cause current leakage through the water, resulting in cardiac arrest or paralysis underwater. The constant risk of gas explosions from hydrogen and oxygen bubbles generated during welding adds another deadly layer.

Decompression sickness, commonly known as “the bends,” occurs when nitrogen bubbles form in a diver’s bloodstream during rapid ascent. It can cause paralysis, brain damage, or death if not treated promptly in a decompression chamber.

Equipment malfunction is also a silent killer. A blocked oxygen hose or a faulty pressure valve can trap a welder in an inescapable situation within seconds.

Why is electric shock more dangerous underwater?

Water conducts electricity efficiently, making even low-voltage leaks potentially fatal.

What causes underwater explosions?

Gas pockets of hydrogen and oxygen can ignite when exposed to an electric arc.

Can decompression sickness be prevented?

Yes — by following slow ascent rates and strict decompression schedules.

Are drowning accidents common?

Unfortunately, yes. Equipment failure or poor visibility can disorient divers, leading to fatal situations.

Does Underwater Welding Shorten Your Life?

This is the question that sparks fear — and curiosity — among welders worldwide. While there isn’t a precise medical study that defines a universal life expectancy, industry data and anecdotal evidence suggest that underwater welders often have shorter careers and lifespans than surface welders.

Some sources estimate the average lifespan of an underwater welder to be around 35–40 years, while others extend it up to 50–55 depending on training, safety compliance, and work conditions (Inspenet).

Several factors influence this reduced life expectancy: prolonged exposure to high pressure, toxic fumes, fatigue, and extreme temperatures all wear down the human body faster. The stress of repeated deep-sea dives can affect circulation, respiration, and even cognitive health over time.

However, it’s not accurate to say that underwater welding automatically shortens your life. Many divers retire safely after years of disciplined work. The determining factor isn’t the profession itself — it’s the level of training, safety discipline, and company standards followed.

What’s the average life expectancy of an underwater welder?

It varies widely — typically between 35 to 55 years, depending on health and safety factors.

Are these statistics reliable?

Most are based on industry observations, not global studies, so they serve as indicators, not certainties.

Can proper safety practices extend a welder’s life?

Absolutely. Following strict decompression and equipment protocols greatly reduces risk.

Biological and Health Effects on Welders

Beyond sudden accidents, underwater welding takes a gradual toll on the human body. Every dive subjects the body to extreme pressure, reduced oxygen, and toxic fume exposure — leading to both short-term and chronic health effects.

High pressure compresses body tissues, causing barotrauma — damage to lungs, ears, and sinuses. Repeated exposure may result in joint pain, nerve damage, or chronic fatigue. Prolonged contact with metal fumes, ozone, and carbon monoxide also increases risks of lung disease and cancer.

The underwater environment amplifies these effects. Even small errors in decompression or gas mixing can lead to nitrogen narcosis, oxygen toxicity, or blackouts. Over time, this can accelerate aging and reduce overall health resilience.

While not all underwater welders experience severe illness, studies have linked diving professions with higher rates of neurological and respiratory problems.

How does pressure affect the body underwater?

It compresses tissues and gases, leading to lung and sinus damage if not balanced properly.

Are welding fumes dangerous underwater?

Yes — underwater conditions can trap fumes near the diver’s breathing zone, making inhalation riskier.

What organs are most affected?

The lungs, ears, nervous system, and joints face the most stress from repeated dives.

Does this job accelerate aging?

Chronic pressure exposure and fatigue can cause premature joint wear and vascular strain.

Safety Measures, Training, and Modern Innovations

Despite its dangers, underwater welding has become safer than it once was. Improved training programs, equipment standards, and safety monitoring have drastically reduced fatalities in the last decade.

All professional underwater welders are required to be certified commercial divers trained under organizations like ADCI (Association of Diving Contractors International) or IMCA (International Marine Contractors Association). They must undergo rigorous physical exams, dive simulations, and continuous safety assessments.

Modern welding systems now include insulated power cables, arc control units, and automated shutoff switches that minimize electric risk. Divers also follow surface monitoring protocols with real-time communication and oxygen tracking.

Some companies are moving toward robotic underwater welding to reduce direct human exposure. Remotely operated vehicles (ROVs) and automated habitats now perform tasks that once required human divers, especially in high-risk zones like oil platforms.

What are the top safety protocols underwater welders follow?

They include pre-dive checks, decompression logs, insulated tools, and emergency recovery drills.

How does training reduce fatality?

Proper training teaches welders to anticipate danger, manage gas balance, and respond quickly to electrical faults.

Are robotic welders replacing humans?

In deep or high-pressure jobs, yes — automation is becoming more common to protect human life.

Can medical monitoring prevent long-term damage?

Yes — regular health screenings detect early signs of decompression or fume-related issues.

Trends and Future Outlook

The demand for underwater welders remains strong across marine construction, energy infrastructure, and offshore wind projects. However, the profession is evolving rapidly with safety and technology.

Robotics and AI-driven underwater systems are replacing manual tasks in dangerous depths, allowing human divers to focus on inspection, planning, and supervision. This shift is improving safety and extending the average career length of skilled welders.

Global regulations are also tightening, with more countries enforcing strict diving standards and real-time monitoring systems for underwater work. These changes are reducing accidents and improving working conditions year by year.

While underwater welding may never be entirely risk-free, modern advancements mean that welders today face far fewer dangers than those of previous generations.

Is underwater welding declining as a career?

Not declining — but transitioning toward automation-assisted roles.

Will technology make it safer?

Yes — new innovations are expected to cut accident rates by over 50% in the next decade.

Can welders shift to safer roles later in their careers?

Absolutely. Many move into inspection, training, or surface coordination positions.

Conclusion

So, does underwater welding shorten your life? The honest answer — it can, but it doesn’t have to.

This profession carries undeniable risks. Constant exposure to pressure, electricity, and toxic gases can shorten both career and lifespan if safety rules are ignored. But with modern technology, rigorous training, and strict adherence to diving protocols, many welders complete long, successful careers without serious harm.

Ultimately, underwater welding isn’t about danger alone — it’s about discipline, awareness, and respect for the environment you work in. Those who treat the craft seriously can extend both their career and life expectancy far beyond the stereotypes.

If you’re drawn to the thrill and reward of welding beneath the waves, pursue it — but do so wisely. Invest in proper training, maintain your health, and always prioritize safety over speed. Because at the end of the day, it’s not the water that shortens your life — it’s the lack of preparation.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.