The best electrode for welding galvanized steel is a zinc-based electrode. This type of electrode is specifically designed to work well with the zinc coating on galvanized steel, ensuring a strong and durable weld.

Welding galvanized steel requires careful selection of the right electrode to ensure a successful and effective welding process. The zinc coating on galvanized steel poses challenges due to its unique properties. Therefore, using a zinc-based electrode is crucial for achieving optimal results.

This type of electrode is formulated to provide excellent adhesion to the zinc coating while maintaining the integrity of the weld. In this blog post, we will explore the reasons why a zinc-based electrode is the best choice for welding galvanized steel and discuss its advantages over other alternatives. So, let’s dive in and discover the key considerations when selecting the perfect electrode for this specific application.

Photo by servintegrales

Galvanized Steel Welding

Galvanized steel is a popular material in many industries due to its corrosion resistance and durability. However, welding galvanized steel presents a unique challenge due to the presence of a zinc coating on the surface. When heated, the zinc coating can release toxic fumes, making it essential to use the correct electrode for welding galvanized steel. In this article, we will explore the benefits of welding galvanized steel and identify the best electrode for the job.

Challenge With Galvanized Steel

Welding galvanized steel presents a challenge due to the presence of a zinc coating on the surface. When heated, the zinc coating can release toxic fumes that can be harmful to the welder. The zinc coating can interfere with the welding process, leading to poor weld quality and porosity. To overcome these challenges, it is essential to use the correct electrode when welding galvanized steel.

Benefits Of Welding Galvanized Steel

Galvanized steel is a popular material due to its durability and corrosion resistance. Welding galvanized steel allows for the creation of strong, long-lasting structures that can withstand harsh environments. Welding galvanized steel is cost-effective and requires minimal maintenance, making it an ideal material for a wide range of applications.

Best Electrode For Welding Galvanized Steel

When welding galvanized steel, it is essential to use an electrode specifically designed for the job. The best electrode for welding galvanized steel is a low-hydrogen electrode, such as an E7018 stick electrode. These electrodes are designed to produce strong welds while minimizing the risk of porosity and other defects. Low-hydrogen electrodes produce minimal spatter, making them easy to use and clean up.

When welding galvanized steel, it is also important to properly prepare the surface by removing any zinc coating near the weld area. This can be achieved through grinding or brushing, ensuring a clean surface for the electrode to bond with. By following these guidelines and using the correct electrode, welding galvanized steel can be a safe and effective process.

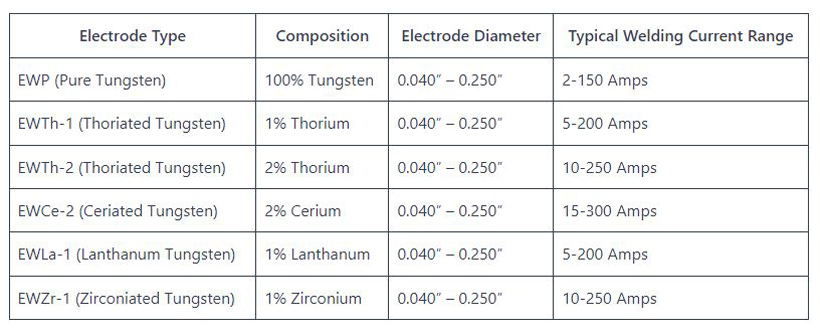

Types Of Welding Electrodes

- Composition determines electrode suitability for specific welding tasks.

- Diameter impacts weld penetration and deposition rate.

- Coating influences arc stability and weld appearance.

Characteristics Of Welding Electrodes

Electrodes vary based on composition, diameter, and coating.

Composition impacts suitability for different welding tasks.

Selecting The Right Electrode

- Consider material thickness and welding position.

- Choose electrode based on required mechanical properties.

- Ensure compatibility with base metal and welding equipment.

Why Electrode Choice Matters

Selecting the right electrode is crucial for welding galvanized steel due to the zinc coating. A high-quality electrode designed specifically for galvanized steel welding is essential to ensure a strong and durable bond. Using the best electrode will help prevent issues such as porosity, cracking, and excessive spatter, resulting in a high-quality weld.

Choosing the right electrode for welding galvanized steel is crucial for achieving optimal weld quality and ensuring safety. The electrode you select can have a significant impact on the overall performance and durability of the welded joint. Considering the safety considerations associated with welding galvanized steel is essential to prevent potential health hazards.

Impact On Weld Quality

When it comes to welding galvanized steel, the choice of electrode plays a vital role in determining the quality of the weld. Different electrodes have varying compositions and coatings, which can affect the weld’s strength, appearance, and resistance to corrosion. Using the wrong electrode can lead to weak welds, porosity, and reduced mechanical properties, jeopardizing the integrity of the welded joint.

By selecting an electrode specifically designed for welding galvanized steel, you can ensure a strong and durable weld. These electrodes are formulated to provide excellent penetration and fusion with the galvanized coating, resulting in a robust joint that can withstand the rigors of various applications.

Safety Considerations

When welding galvanized steel, safety should always be a top priority. Galvanized coatings contain zinc, which emits harmful fumes when heated. These fumes can cause respiratory issues, eye irritation, and other health problems if proper precautions are not taken. Therefore, selecting the right electrode can help minimize the risk of exposure to these hazardous fumes.

Electrodes with low levels of zinc content and specific coatings can help reduce the emission of harmful fumes during welding. These electrodes are designed to provide better arc stability and produce less smoke, protecting both the welder and the surrounding environment.

Using the correct electrode can also contribute to better overall welding safety. The right electrode will offer improved control and ease of use, reducing the chances of weld defects, spatter, and other welding-related accidents.

The choice of electrode for welding galvanized steel significantly impacts weld quality and safety. By selecting an electrode tailored for this specific application, you can ensure strong, durable welds while minimizing health risks associated with welding galvanized steel.

Recommended Electrodes For Galvanized Steel

E6010 Electrodes

E6010 electrodes are an excellent choice for welding galvanized steel due to their deep penetration and strong arc force. These electrodes are specifically designed to cut through the zinc coating, allowing for a strong bond between the base metal and the weld deposit. They are ideal for root passes on galvanized steel and are often used in the construction industry.

E6011 Electrodes

When it comes to welding galvanized steel, E6011 electrodes are a popular choice. These electrodes produce a strong, penetrating arc that effectively burns through the zinc coating. They are versatile and can be used in various welding positions, making them suitable for a wide range of applications in industries such as automotive, construction, and fabrication.

E6013 Electrodes

E6013 electrodes are known for their smooth and stable arc characteristics, making them suitable for welding galvanized steel. These electrodes create a clean and attractive bead appearance while effectively bonding with the base metal. They are often favored for their ease of use and can be employed in both AC and DC welding processes.

Advantages Of E6013 Electrodes

E6013 electrodes offer several advantages for welding galvanized steel. These electrodes provide excellent arc stability, smooth and clean welds, and easy slag removal. Their low spatter and high deposition rate make them the best choice for welding galvanized steel, ensuring high-quality, durable welds.

Ease Of Use: E6013 electrodes are user-friendly for both beginner and experienced welders.

Versatility: These electrodes can be used in all welding positions for various applications.

Smooth Weld Finish: E6013 electrodes create clean welds with minimal spatter and a smooth appearance.

Preparing For Welding

To prepare for welding galvanized steel, it’s important to select the best electrode. A zinc-coated electrode is recommended as it helps to prevent the zinc from burning off, resulting in a stronger weld and minimal spatter.

Cleaning Galvanized Steel

Before welding, it is essential to clean the galvanized steel thoroughly. Galvanized steel has a layer of zinc coating, which can cause porosity in the weld if not removed properly. Cleaning the steel surface is also crucial for ensuring the proper formation of the weld. Here are the steps to follow for cleaning galvanized steel before welding:

- Use a wire brush or grinder to remove the zinc coating from the area to be welded.

- Wipe the surface with a clean, dry cloth to remove any dust or debris.

- Use a solvent or degreaser to remove any oil or grease from the surface.

- Repeat the process until the surface is clean and free of any contaminants.

Pre-welding Setup

After cleaning the surface, the next step is to set up the welding equipment. Here are the steps to follow for pre-welding setup:

- Choose the appropriate electrode for welding galvanized steel. The best options are E6011, E6013, E7018, or E7024.

- Set the amperage and polarity according to the electrode manufacturer’s recommendations.

- Ensure that the electrode is dry and free of any moisture or contaminants.

- Position the steel pieces to be welded and clamp them securely in place.

- Adjust the welding machine settings to the correct amperage and voltage for the thickness of the steel.

It is important to take extra precautions when welding galvanized steel as the zinc coating can release toxic fumes when heated. Always wear proper personal protective equipment such as a respirator, gloves, and safety glasses to protect yourself from harmful fumes and debris. In conclusion, preparing for welding galvanized steel involves cleaning the surface thoroughly and setting up the welding equipment correctly. By following these steps and taking proper safety precautions, you can ensure a successful and safe welding process.

Welding Techniques For Galvanized Steel

When welding galvanized steel, it’s crucial to choose the right electrode and welding technique to ensure a strong and durable weld. The galvanized coating on the steel can pose challenges during the welding process, leading to issues such as spatter, porosity, and weld cracking. Here, we’ll explore the best welding techniques for galvanized steel, including the use of different transfer methods and shielding gases to achieve optimal results.

Short Circuit Transfer

In the short circuit transfer method, the electrode makes momentary contact with the welding puddle, creating a short circuit. This technique is suitable for welding galvanized steel as it helps to minimize spatter and reduce the risk of burn-through. The short circuit transfer method is ideal for welding thin galvanized steel sections, providing precise control over the weld pool.

Spray Transfer

Spray transfer is another effective technique for welding galvanized steel. It involves using a higher voltage and amperage to achieve a steady stream of molten droplets from the electrode to the workpiece. This method is well-suited for welding thicker galvanized steel sections, delivering high deposition rates and strong, spatter-free welds.

Shielding Gas Considerations

When welding galvanized steel, the choice of shielding gas plays a critical role in the quality of the weld. Using a mixed gas containing a combination of argon and carbon dioxide can help minimize spatter and produce clean welds. The addition of oxygen in the shielding gas can also enhance weld penetration, especially when working with thicker galvanized steel materials.

Post-welding Practices

After completing the welding process on galvanized steel, it is crucial to follow appropriate post-welding practices to ensure the integrity and longevity of the weld. Post-welding practices include cleaning the weld, inspecting the weld, and applying protective coatings.

Cleaning The Weld

Cleaning the weld area is essential to remove any residual zinc oxide and other contaminants that may have accumulated during the welding process. This can be achieved through the use of appropriate cleaning agents and tools, such as wire brushes or abrasive pads, to ensure the weld area is free from any impurities.

Inspecting The Weld

Thorough inspection of the weld is necessary to identify any defects or imperfections that may have occurred during the welding process. This includes visual inspection for cracks, porosity, or incomplete fusion, as well as non-destructive testing methods like ultrasonic testing to ensure the weld meets the required standards of quality and integrity.

Protective Coatings

Applying protective coatings to the welded area is crucial to safeguard the weld from corrosion and environmental damage. This may involve the use of coatings such as zinc-rich paints or other corrosion-resistant materials to provide an additional layer of protection to the weld, extending its lifespan and durability.

Conclusion

Choosing the right electrode is crucial for welding galvanized steel effectively. Always prioritize safety and quality to achieve optimal results. Consider factors like coating thickness, material compatibility, and welding technique when selecting the best electrode. By following these guidelines, you can ensure a successful welding process and durable end product.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.