Ever looked at a shiny aluminum project and wondered how to make those welds look just as good? TIG welding aluminum can be tricky, and picking the wrong filler rod is a surefire way to end up with weak, ugly, or even cracked welds. It’s like trying to build a sturdy house with the wrong kind of nails – it just won’t hold!

Choosing the perfect filler rod for TIG welding aluminum can feel like a puzzle. There are so many types, and each one seems to have its own special job. If you pick the wrong one, your weld might not be strong enough for the job, or it might look rough and unprofessional. This can be frustrating, especially when you want your projects to turn out perfectly.

But don’t worry! This post is here to help you solve that puzzle. We’ll break down what makes different aluminum filler rods tick. By the end, you’ll know exactly which rod to grab for your next aluminum TIG welding project, making your welds strong, clean, and impressive. Get ready to level up your aluminum welding skills!

Our Top 5 Filler Rod For Tig Welding Aluminum Recommendations at a Glance

Top 5 Filler Rod For Tig Welding Aluminum Detailed Reviews

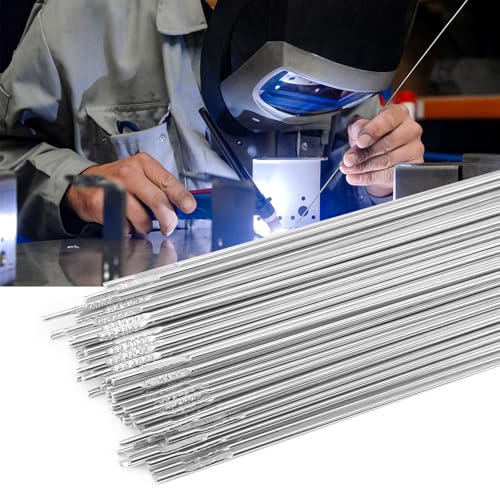

1. Aluminum TIG Welding Rod 3/32″x 16″ 1.8LB

Rating: 9.2/10

This Aluminum TIG Welding Rod, specifically the ER4043 type, is a fantastic tool for anyone working with aluminum. It’s designed to make your TIG welding projects smoother and more successful. With a 5% silicon addition, it helps the melted metal flow better, creating cleaner welds. You’ll also notice less mess, as it produces minimal splatter. Plus, it’s tough and resists corrosion, meaning your welds will last longer.

What We Like:

- Improved melt pool liquidity thanks to 5% added silicon.

- Stable arc and very little splatter means cleaner welds and less cleanup.

- Works with many common aluminum alloys like 3003, 5052, 6061, and more.

- Less likely to crack when welding, giving you more confidence.

- Comes in a convenient 1.8LB package with rods measuring 3/32″ diameter and 16″ length.

What Could Be Improved:

- Requires a shielding gas, usually 100% Argon, Helium, or a mix, adding to the setup cost.

- The 1.8LB weight might be a bit much for very small projects, but it’s great for regular use.

This ER4043 aluminum welding rod is a reliable choice for a wide range of aluminum welding tasks. Its features make it a valuable addition to any TIG welder’s toolkit.

2. ARCCAPTAIN Aluminum TIG Welding Rod ER4043

Rating: 9.2/10

The ARCCAPTAIN Aluminum TIG Welding Rod ER4043 is a fantastic choice for anyone working with aluminum. This 5% silicon alloy welding rod offers excellent flow and can handle high temperatures. Its 3/32″ diameter and 16″ length make it a convenient size for many projects. You can use it with common shielding gases like Argon, Helium, or a mix.

What We Like:

- The ER4043 rod has a high silicon content, which means it melts smoothly and easily.

- It’s great for welding aluminum parts and even cast aluminum pieces.

- You’ll find it used in many industries, like trains, chemical plants, and food processing.

- Welding with these rods creates a clean seam without needing extra cleaning afterward, saving you time.

- The 5LB package provides a good amount of rod for your welding needs.

What Could Be Improved:

- While generally easy to use, beginners might need a little practice to master the technique.

- The 16-inch length might be a bit short for very large projects, requiring more rod changes.

This ARCCAPTAIN welding rod makes aluminum welding more manageable. It’s a reliable option for creating strong, clean welds across various applications.

3. YESWELDER Aluminum TIG Welding Rod ER4043 1/16″x16″ 5LB

Rating: 8.6/10

If you’re looking for a reliable aluminum TIG welding rod, the YESWELDER ER4043 is a great option. This rod is a popular choice for many welders because it’s easy to use and works well for many different jobs. It’s made with 5% silicon, which helps it flow smoothly when you’re welding.

What We Like:

- It’s a very common type of aluminum welding wire, so many welders know how to use it well.

- The silicon in the rod makes the melted aluminum flow easily, which helps create neat welds.

- It’s less likely to crack when you’re welding, which means fewer problems and better results.

- Welds made with this rod come out looking brighter and cleaner.

- You can use it on many different kinds of aluminum, including those that have been heated or treated.

- It works on both cast and forged aluminum parts.

- It’s good for welding common aluminum grades like 3003, 5052, and 6061.

- It also works well on casting alloys like 43 and 356.

- You usually need to use 100% Argon gas with it for the best results.

What Could Be Improved:

- While versatile, it might not be the absolute best choice for extremely high-strength aluminum alloys where specific filler metals are recommended.

This YESWELDER ER4043 rod is a solid performer for general aluminum welding. It makes your welding job easier and helps you get strong, good-looking welds.

4. UNIFAMILY 60Pcs Aluminum Welding Rods ER4043 1/16″ x 16″

Rating: 8.5/10

If you’re looking for reliable aluminum welding rods, the UNIFAMILY 60Pcs Aluminum Welding Rods ER4043 are a solid choice. These rods are designed for TIG welding and offer good performance for various projects. They come in a generous pack, so you’ll have plenty to work with.

What We Like:

- You get 60 rods, which is a lot for the price.

- They are easy to use and create smooth welds.

- The rods have a stable arc and don’t make too much splatter.

- They are made of good quality aluminum and resist rust.

- The 1/16″ x 16″ size is handy for many different welding jobs.

- They work well for mild and low-alloy steels.

- These rods are suitable for many industries like construction and automotive.

What Could Be Improved:

- While they are good for mild and low-alloy steels, they might not be the best for all types of aluminum.

- The “low temp” aspect is mentioned, but specific temperature ranges or benefits aren’t detailed.

Overall, these UNIFAMILY ER4043 welding rods offer good value and performance for many common TIG welding needs. They are a practical option for DIYers and professionals alike.

5. YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB

Rating: 9.5/10

If you’re looking for a reliable aluminum welding rod, the YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB is a great choice. This rod is a workhorse for many welding jobs. It’s made with 5% silicon, which helps it melt smoothly and easily. This makes it a favorite among welders for all sorts of projects.

What We Like:

- ER4043 is a very popular and trusted aluminum welding wire.

- It has 5% silicon, which makes it melt easily.

- This rod is less likely to crack when you weld with it.

- It produces welds that look brighter and cleaner.

- You can use it on many different types of aluminum, including cast metals.

- It’s good for metals that will be heated later.

- You usually just need 100% Argon gas to use it.

What Could Be Improved:

- The 5LB package might be more than some hobbyists need at once.

- While versatile, it’s not the best for all high-strength aluminum alloys.

This YESWELDER rod is a solid performer for general aluminum welding. You can count on it for many common applications.

Choosing the Right Filler Rod for TIG Welding Aluminum

TIG welding aluminum lets you create strong, clean, and good-looking welds. But picking the right filler rod is super important. It’s like choosing the right glue for a project. The wrong rod can lead to weak welds or ugly messes. This guide will help you find the best filler rod for your aluminum TIG welding adventures.

Key Features to Look For

When you’re shopping for aluminum filler rods, keep these important features in mind:

- Material Type: Aluminum comes in many different types, and your filler rod needs to match.

- Diameter: The rod’s thickness matters for different weld sizes.

- Length: Most rods come in standard lengths, but it’s good to know what you need.

- Packaging: Rods should be clean and protected from moisture.

Important Materials: Understanding Aluminum Alloys

Aluminum isn’t just one thing. It’s an alloy, which means it’s a mix of aluminum with other metals. Different alloys have different strengths and how they behave when welded. The most common ones you’ll see are:

- 1100 Series (Pure Aluminum): This is almost pure aluminum. It’s soft and easy to bend. It’s good for things like tanks or when you need to do a lot of bending after welding.

- 4043 Series: This is a very popular choice. It has silicon added. Silicon helps the weld flow better and makes it less likely to crack. It’s great for most general aluminum welding jobs.

- 5356 Series: This one has magnesium. It’s stronger than 4043 and has a brighter weld color, which looks nice. It’s good for applications where strength is key, like boat parts or frames.

Choosing the right alloy for your filler rod is crucial. It needs to be compatible with the aluminum you are welding. Using the wrong filler rod can cause cracks or a weak weld.

Factors That Improve or Reduce Quality

Several things can make your filler rod work better or worse:

- Cleanliness: The rod must be clean. Grease, oil, or dirt can cause weld defects. Always wipe down your filler rod with a clean cloth and maybe a little acetone before you weld.

- Oxide Layer: Aluminum naturally forms an oxide layer. You need to clean this off the base metal and the rod before welding. This is usually done with a stainless steel wire brush.

- Storage: Keep your filler rods in a dry place. Moisture can make them harder to work with and can cause problems in the weld.

- Matching Alloys: As mentioned, using a filler rod that matches your base aluminum alloy is key. If you’re unsure, 4043 is often a safe bet for many common aluminum types.

A good quality rod will be consistent in its diameter and free from any surface imperfections. Poorly made rods might have rough edges or be bent, making them difficult to feed into the weld puddle.

User Experience and Use Cases

People use aluminum filler rods for all sorts of projects.

- Hobbyists: Many DIYers use aluminum filler rods for projects like building custom bike frames, making metal art, or repairing aluminum parts on their cars.

- Professional Welders: In industries like aerospace, automotive, and marine, aluminum TIG welding is common. Professionals use it for everything from building airplane components to fabricating boat hulls and creating intricate metal sculptures.

The experience of welding with different rods can vary.

- 4043: Many beginners find 4043 easy to use because it flows smoothly and is forgiving.

- 5356: Welders who need extra strength and a good appearance often prefer 5356. It can sometimes be a bit trickier to control than 4043 for absolute beginners, but it offers superior mechanical properties.

Always remember to practice on scrap pieces first. This helps you get a feel for how the rod melts and flows with your specific welding machine settings.

Frequently Asked Questions (FAQ)

Q: What is the most common type of aluminum filler rod?

A: The most common type is 4043. It works well for many different aluminum alloys and is easy to use.

Q: Can I use 4043 filler rod on all aluminum?

A: No, you should try to match the filler rod to the aluminum you are welding. However, 4043 is a good general-purpose rod for many common alloys.

Q: How do I clean aluminum before TIG welding?

A: You need to remove any dirt, grease, or the oxide layer. Use a stainless steel wire brush and a degreaser like acetone.

Q: What diameter filler rod should I use?

A: The diameter depends on the thickness of the aluminum you are welding. Thicker aluminum needs a thicker rod, and thinner aluminum needs a thinner rod.

Q: Does the color of the weld matter?

A: Sometimes. 5356 filler rod often gives a brighter, shinier weld than 4043, which can be important for appearance.

Q: How do I store my aluminum filler rods?

A: Store them in a dry place. A sealed container or a plastic tube can help keep them clean and dry.

Q: What happens if I use the wrong filler rod?

A: You might get cracks in your weld, the weld might be weak, or it might not look good.

Q: Is it okay to touch the filler rod to the tungsten?

A: No, you should never let the filler rod touch the tungsten electrode. This can contaminate the tungsten and ruin your weld.

Q: Can I use steel wool to clean aluminum?

A: No, steel wool can leave small particles that can cause problems in the weld. Always use a stainless steel wire brush.

Q: Where can I buy aluminum filler rods?

A: You can find them at welding supply stores, online retailers, and some hardware stores.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.