Achieving a clean, strong, and aesthetically pleasing weld on aluminum with the TIG process hinges on one critical choice: the shielding gas. While many welders know that pure Argon is the standard, unlocking the full potential of your machine often requires a deeper understanding of how different gas compositions affect the arc, the weld puddle, and the final result.

The properties of aluminum—its high thermal conductivity and tenacious oxide layer—demand a gas that provides excellent cleaning action, stability, and sufficient heat input. Selecting from the best 5 gases for aluminum TIG welding allows you to precisely match your gas to your project’s specific demands, whether you’re working on thin auto-body panels or thick structural plate.

Pure Argon is the undisputed champion and the recommended starting point for most aluminum TIG welding, especially for material under 1/2 inch thick. It offers exceptional arc stability, effective oxide removal, and great control over the weld puddle. However, as you move to thicker sections, pure

Argon’s limitations can become apparent, sometimes resulting in a wide, shallow penetration profile and slower travel speeds. This is where introducing helium into the mix becomes a game-changer. Helium, with its higher thermal conductivity, raises the arc temperature and voltage, leading to a hotter, more penetrating arc that increases travel speed and improves weld pool fluidity on heavy material.

From the universal purity of 100% Argon to specialized ternary blends, each gas has a specific role. This guide will detail the best 5 gases for aluminum TIG welding, explaining the pros, cons, and ideal applications for each to help you optimize your shielding gas for superior weld quality, efficiency, and penetration on every aluminum project.

Our Top 5 Gas For Aluminum Tig Welding Recommendations at a Glance

Top 5 Gas For Aluminum Tig Welding Detailed Reviews

1. Aluminum TIG Welding Rod 3/32″x 16″ 1.8LB

Rating: 9.2/10

This Aluminum TIG Welding Rod is a great helper for your aluminum welding projects. It’s designed to make your welds look good and last long. The 5% silicon added helps the melted metal flow smoothly. This means you get better control and cleaner-looking welds. You can use it with common shielding gases like 100% Argon or Helium for best results. It works with many different types of aluminum, making it super versatile for various jobs.

What We Like:

- The added silicon makes the melted aluminum flow really well, which helps create smooth welds.

- It’s less likely to crack when you weld, giving you stronger joints.

- The arc stays steady, and it doesn’t spit out much molten metal, so your workspace stays cleaner.

- It works with a lot of different aluminum alloys, from common ones like 6061 to casting alloys.

- Comes in handy sizes like 3/32″ diameter and 16″ length, with a good weight of 1.8LB.

What Could Be Improved:

- The instructions mention needing gas, so you have to make sure you have the right shielding gas ready to go.

This welding rod is a solid choice for anyone looking to achieve strong, clean aluminum welds with less hassle. It offers great performance and versatility for many different projects.

2. YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB

Rating: 8.9/10

The YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB is a solid choice for many aluminum welding projects. This rod is a workhorse in the welding world, known for its reliability and ease of use. If you’re looking to join different aluminum parts, this rod will likely get the job done.

What We Like:

- ER4043 is a classic for a reason. It’s called “AlSi5” and has 5% silicon, making it super popular for general aluminum welding.

- It melts smoothly, which makes welding easier for beginners and pros alike.

- Welds made with this rod are less likely to crack, giving you more confidence in your work.

- The finished welds look brighter and cleaner.

- This rod works on a bunch of different aluminum types, including common ones like 3003, 5052, and 6061. It’s also good for cast aluminum.

- You can use it on materials that need heat treatment later.

- It works well with 100% Argon shielding gas, which is easy to find.

What Could Be Improved:

- While versatile, it’s not the best choice for aluminum that needs to be anodized after welding, as the silicon can affect the finish.

- For very high-strength applications or specific aluminum alloys, other filler metals might be a better fit.

Overall, the YESWELDER ER4043 rods are a dependable option for most aluminum TIG welding tasks. They offer a good balance of performance and ease of use, making them a smart buy for your shop.

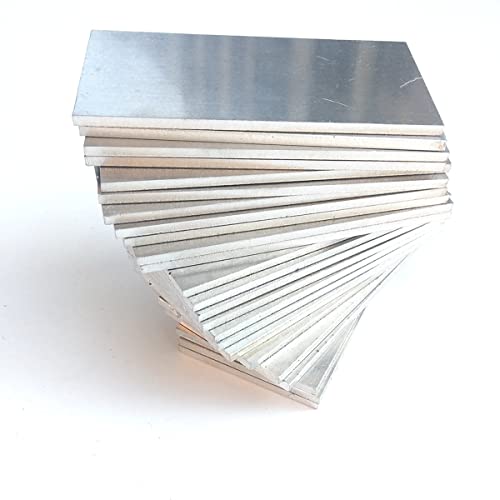

3. Biscuits Welding Practice Aluminum Parts- 5052 Aluminum – 2*4inch- 24Tablets-Very Suitable- Practice and Training for MIG

Rating: 9.4/10

Master your welding skills with Biscuits Welding Practice Aluminum Parts. These 2×4 inch, 0.125 inch thick plates are made from 5052 aluminum. You get 24 pieces, which is a lot for practicing. They are perfect for learning MIG, TIG, Stick, Arc, Gas, and Brazing. Beginners will find these very helpful. Practicing with these plates will make you a better welder. You will feel good and happy as you get better.

What We Like:

- Great for beginners: These plates help new welders learn different welding styles.

- Good quality material: Made from 5052 aluminum, which is good for practice.

- Plenty to practice with: 24 pieces means you can practice a lot without running out.

- Versatile: Works for MIG, TIG, Stick, Arc, Gas, and Brazing.

- Skill improvement: Practicing on these helps you get better and gain confidence.

- Satisfying results: You will feel a sense of accomplishment as your welding improves.

What Could Be Improved:

- Size limitation: The 2×4 inch size might not be big enough for some advanced projects.

- Material only: These are for practice and training, not for final projects.

These aluminum practice plates are a fantastic tool for anyone wanting to learn or improve their welding. Get ready to build your confidence and skills!

4. YESWELDER Aluminum TIG Welding Rod ER4043 1/16″x16″ 5LB

Rating: 8.5/10

The YESWELDER Aluminum TIG Welding Rod ER4043 is a go-to choice for many welders. This rod is known for its versatility and ease of use. It’s made with 5% silicon, which helps it flow smoothly when you weld. This makes it a favorite for all sorts of projects.

What We Like:

- It’s called “AlSi5” and is a very popular choice for general aluminum welding.

- The silicon makes it easy to work with and gives you a brighter weld.

- It’s less likely to crack when you’re welding.

- You can use it on many different types of aluminum, including those that have been heat-treated.

- It works well on cast and forged aluminum parts too.

- It’s great for welding common aluminum grades like 3003, 5052, and 6061.

- It also bonds well with casting alloys like 43 and 356.

What Could Be Improved:

- For best results, you’ll need 100% Argon, Helium, or a mix as your shielding gas.

This ER4043 rod is a solid performer for many aluminum welding tasks. It offers good results and is a reliable option for your workshop.

5. 20 Pack 6061 T6 Aluminum Sheet Welding Kit 1/8” Thick 2” x 4” Welding Coupons Weld Practice Kits Beginners for Mig Tig Stick Mma Arc Gas and Brazing Heat Treatable Corrosion Resistant

Rating: 9.3/10

Master your welding skills with the Certiweld Supplies 20 Pack of 6061 T6 Aluminum Sheet Welding Coupons. These 1/8” thick, 2” x 4” practice kits are ideal for beginners learning MIG, TIG, Stick, MMA, Arc, Gas, and Brazing. They are heat treatable, corrosion-resistant, and made in the USA from high-grade materials. This kit offers a fantastic way to hone your technique and build confidence.

What We Like:

- Standard size coupons make practice uniform for MIG, TIG, and stick welding.

- Versatile for various welding methods like MIG, TIG, and stick.

- Made in the USA with top-quality materials for lasting durability.

- Rust-resistant and precisely packaged to ensure you receive them in perfect condition.

- Great for workshops, classrooms, and DIY projects, offering endless practice possibilities.

What Could Be Improved:

- This specific kit focuses only on aluminum; other material options are available separately.

- The thickness is 1/8”, which might not suit all advanced practice needs.

This welding coupon kit is a top-notch resource for anyone looking to improve their welding abilities. It provides reliable practice material for a wide range of applications.

Your Guide to the Best Gas for Aluminum TIG Welding

Aluminum TIG welding can be tricky. The right shielding gas makes a big difference. It helps you make strong, clean welds. This guide will help you choose the best gas.

What to Look For in Shielding Gas

Key features help you pick the right gas. You want a gas that protects your weld pool. It also helps control the arc.

- **Purity:** High purity gas is best. It means fewer impurities. Impurities can cause weld defects.

- **Flow Rate:** You need to set the right flow rate. Too little gas won’t protect the weld. Too much gas can cause turbulence.

- **Mixture:** Some jobs need a mix of gases. The right mix can improve weld appearance and penetration.

Important Materials and Their Gas Needs

Aluminum comes in different types. Each type might like a slightly different gas.

- Pure Aluminum: This is soft. It melts easily. Pure Argon is usually the best choice. It gives a wide, stable arc.

- Aluminum Alloys: These are stronger. They have other metals mixed in. For most aluminum alloys, a mix of Argon and Helium is good. Helium helps with heat. It makes the weld pool flow better.

- Thicker Aluminum: For thicker aluminum, you might need more heat. Adding Helium to Argon helps. It makes the arc hotter. This lets you melt thicker pieces.

What Makes a Weld Better or Worse?

Many things affect your weld quality.

- Gas Purity: Like we said, pure gas is important. Dirty gas makes bad welds.

- Flow Rate: If the flow rate is wrong, you can get problems. Too low, and the air gets to your hot metal. This causes oxidation. Too high, and the gas blows the arc around. This makes the weld look messy.

- Gas Mix: The right mix is key. For aluminum, pure Argon is good for thin stuff. For thicker or harder-to-weld alloys, adding Helium helps. It gives you better heat and penetration.

- Contamination: Keep your gas bottles clean. Keep your welding area clean. Any dirt or oil can ruin your weld.

User Experience and When to Use What

Most aluminum TIG welders use Argon. It is the most common and easiest to use.

- Beginner Welders: Start with 100% Argon. It is forgiving. It works well for most thin aluminum projects. Think bike frames or simple sheet metal.

- Experienced Welders: You might experiment with Argon-Helium mixes. These mixes are good for thicker aluminum. They can also make your welds look nicer. You might use them for boat building or automotive parts.

- Specific Alloys: Some special aluminum alloys might need a specific gas mix. Always check your welding guide or the material manufacturer’s advice.

Frequently Asked Questions About Aluminum TIG Welding Gas

Q: What is the most common gas for TIG welding aluminum?

A: The most common gas is 100% pure Argon. It works well for most aluminum jobs.

Q: Can I use pure Helium for aluminum TIG welding?

A: Pure Helium is not usually used alone for aluminum. It can make the arc too hot and hard to control. It’s usually mixed with Argon.

Q: How much gas should I use?

A: The flow rate depends on your machine, the gas, and the thickness of the metal. A good starting point is usually 15-25 cubic feet per hour (CFH).

Q: What happens if I use too little gas?

A: If you use too little gas, the weld will not be protected. This leads to oxidation and weak welds. You will see a dull, powdery surface on your weld.

Q: What happens if I use too much gas?

A: Too much gas can cause the arc to become unstable. It can also create turbulence that pulls air into the weld pool. This can also cause defects.

Q: What is an Argon-Helium mix for aluminum?

A: It is a blend of Argon and Helium gas. Common mixes are 75% Argon / 25% Helium or 50% Argon / 50% Helium.

Q: When should I use an Argon-Helium mix?

A: You should use an Argon-Helium mix for thicker aluminum. It provides more heat and better penetration. It can also help with cleaning the aluminum surface.

Q: Does the gas affect the look of the weld?

A: Yes, the gas can affect the look. Pure Argon often gives a shiny, clean weld. Argon-Helium mixes can sometimes give a slightly different sheen.

Q: Do I need different gas for different types of aluminum?

A: Yes, sometimes. Pure aluminum is different from aluminum alloys. Thicker aluminum needs more heat than thin aluminum.

Q: Where can I buy shielding gas for TIG welding?

A: You can buy shielding gas from welding supply stores. You will need to rent or buy a cylinder.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.