Ever looked at a shiny stainless steel project and wondered how to get those perfect, clean welds? It’s not magic, but it does take the right tools, and one of the most important is the shielding gas you use for MIG welding. Choosing the wrong gas can lead to all sorts of headaches: ugly spatter, weak welds, or even damage to the metal’s shiny finish. It’s a common problem for welders, whether you’re just starting out or have been welding for a while. There are so many different gas mixes out there, and figuring out which one is best for stainless steel can feel like a puzzle.

But don’t worry, understanding this crucial element doesn’t have to be complicated. In this post, we’re going to break down exactly what you need to know about gases for MIG welding stainless steel. You’ll learn what makes certain gases work better than others and discover how to pick the perfect shield for your projects. By the end, you’ll feel confident in your choice, ready to create strong, beautiful stainless steel welds every time. Let’s dive in and unlock the secrets to a flawless MIG weld on stainless steel.

Our Top 5 Gas For Mig Welding Stainless Steel Recommendations at a Glance

Top 5 Gas For Mig Welding Stainless Steel Detailed Reviews

1. YESWELDER Stainless Steel Flux Cored MIG Wire

Rating: 9.2/10

This YESWELDER Stainless Steel Flux Cored MIG Wire is a great choice for your stainless steel welding projects. Its self-shielding design makes it easy to use, especially outdoors. This wire helps you create strong welds that can stand up to corrosion.

What We Like:

- The flux core inside helps stabilize the arc for smoother welding.

- It works well in all positions, from flat to overhead.

- You don’t need extra shielding gas, making it convenient and portable.

- It’s perfect for welding common stainless steels like 304 and 308.

- The welds are strong and resist rust, just like the metal you’re welding.

- The plastic spool is tough and won’t break easily.

What Could Be Improved:

- The 2-pound spool might be small for very large projects, requiring more frequent changes.

- While versatile, it’s specifically for stainless steel and not for other metals.

This wire makes welding stainless steel easier and more efficient. It’s a reliable option for many different welding jobs.

2. E308LFC-O .035-Diameter Stainless Flux Core Welding Wire

Rating: 8.8/10

This SONNLER E308LFC-O .035-inch stainless flux core welding wire is a fantastic choice for your stainless steel projects. It’s designed to make welding easier and more efficient. You can use it on many types of stainless steel, like 304, 304L, 308, 308L, 321, and 347. The best part? You don’t need a gas tank, which saves you time and effort. This wire is made to work with all MIG welders, making it super versatile.

What We Like:

- No gas needed, so welding is faster and simpler.

- Works on many common stainless steel types.

- Comes in professional, sealed packaging to keep it dry and in good condition.

- It produces very little splatter, which means less mess and easier cleanup after welding.

- Great performance on clean metal.

- Works with many popular MIG welder brands.

- Good for both experienced welders and beginners.

- Excellent customer support with experienced technical help available.

What Could Be Improved:

- The 2-pound spool size might be too small for very large projects.

This SONNLER welding wire offers excellent performance and value for anyone working with stainless steel. It’s a reliable option that simplifies the welding process and delivers great results.

3. PGN Stainless Steel MIG Welding Wire – ER308L .035 Inch – 10 Pound Spool – Low-Carbon Mild Steel MIG Wire for Reduced Splatter and Better Corrosion Resistance – For All Position Gas Welding

Rating: 8.7/10

Get ready to weld like a pro with the PGN Stainless Steel MIG Welding Wire! This ER308L wire, measuring .035 inches and coming on a hefty 10-pound spool, is designed for serious stainless steel projects. It’s a low-carbon mild steel MIG wire that promises less mess and better protection against rust, making it ideal for all sorts of welding positions.

What We Like:

- Low carbon content creates super clean welds and helps prevent rust.

- Works great on many common stainless steels like 304, 304L, and 308L.

- Produces very little splatter, leading to neat and precise welds.

- Offers excellent value with a large 10-pound spool at a good price.

- Carefully packaged to avoid frustrating tangles.

- Made by a company that cares about quality and standards.

What Could Be Improved:

- It requires a shielding gas like argon or argon/helium, which is an extra cost and setup.

- While it works on many stainless steels, it’s not for every type.

This PGN MIG welding wire is a fantastic choice for anyone looking for reliable, high-quality results without breaking the bank. You’ll achieve impressive welds with less cleanup and enjoy the peace of mind that comes with durable, corrosion-resistant work.

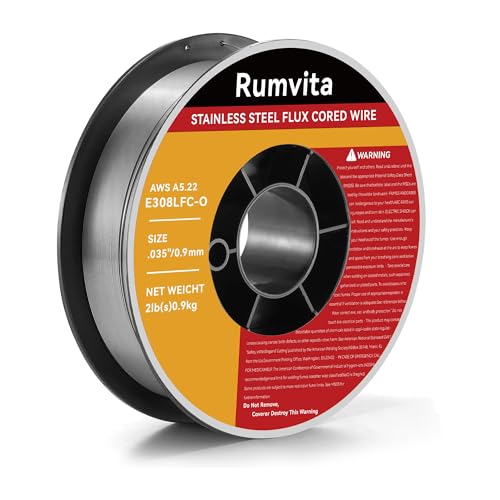

4. Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter

Rating: 9.2/10

This Rumvita Stainless Steel Flux Cored Wire is a game-changer for your welding projects. It’s a .035-diameter MIG welding wire designed for stainless steel. This wire uses an internal flux core, which helps keep the arc steady and makes welding easier. It also creates a protective shield around your weld. Plus, it’s made to work with all MIG welders, and you don’t need extra gas for it!

What We Like:

- The E308LFC-O flux core makes the arc stable and protects your weld.

- It works great in all welding positions and makes very little spatter.

- You’ll spend less time cleaning up slag because there’s almost none.

- It creates nice-looking welds, which means you can get more done faster.

- This wire works with many types of stainless steel, like 304, 304L, 308, 308L, 321, and 347.

- You don’t need to use shielding gas, saving you time and money.

- Each 2-pound spool is packed in a vacuum-sealed bag to keep it fresh.

- It’s designed for both experienced welders and beginners.

- The company offers 7*24 service if you have any questions.

What Could Be Improved:

- While it’s gasless, some very complex or specialized stainless steel projects might still benefit from gas.

- For extremely long welding sessions, a larger spool size might be more convenient for some users.

This stainless steel flux cored wire makes welding easier and more efficient. It’s a solid choice for anyone looking to weld stainless steel with their MIG welder.

5. ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L

Rating: 8.6/10

Achieve professional-grade welds with the ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L. This 0.030-inch diameter, 2-pound spool is designed for MIG welders, offering low splatter and excellent performance for various stainless steel projects. It’s compatible with popular brands like Lincoln, Miller, Forney, and Harbor.

What We Like:

- This wire is made with low carbon, which helps prevent rust and makes your welds stronger.

- It works great on many types of stainless steel, like what’s used in kitchens and hospitals.

- You get clean welds with very little mess, making your work look better.

- The wire is tough and won’t rust easily, so your welds last a long time.

- It gives you good control when you’re welding, even for tricky spots.

What Could Be Improved:

- The 2-pound spool might be a bit small for very large projects, requiring you to change spools more often.

- While compatible with many welders, it’s always good to double-check your specific machine’s manual.

This ARCCAPTAIN MIG wire is a solid choice for anyone needing reliable and high-quality stainless steel welds. It makes difficult jobs much easier and delivers results you can be proud of.

Choosing the Right Gas for MIG Welding Stainless Steel

When you’re MIG welding stainless steel, the gas you use is super important. It helps make your welds strong and look good. Let’s figure out the best gas for your projects.

1. Key Features to Look For

Think about these things when picking your gas:

- Shielding Power: The gas needs to protect your hot metal from the air. Air has oxygen and nitrogen, which can make stainless steel weak and rusty.

- Arc Stability: A good gas makes the welding arc smooth and steady. This means you have more control.

- Clean Welds: You want welds that are clean and don’t have a lot of splatter. Splatter is like little metal blobs that fly off.

- Cost: Some gases are more expensive than others. Think about your budget.

2. Important Materials

For MIG welding stainless steel, you’ll mostly be using these gases:

- Argon: This is the most common gas for MIG welding. It’s great at shielding.

- Carbon Dioxide (CO2): CO2 helps with penetration, meaning the weld goes deeper into the metal. But too much CO2 can hurt the stainless steel’s look and strength.

- Oxygen (O2): A tiny bit of oxygen can sometimes help with arc stability and make the weld flow better. But like CO2, too much is bad.

3. Factors That Improve or Reduce Quality

What makes a good weld, and what makes a bad one?

- Gas Mix: The mix of gases is the biggest factor. For stainless steel, you usually want a mix with more argon. A common mix is 90% Argon and 10% CO2. Sometimes, a mix with a little bit of oxygen is used.

- Flow Rate: How much gas comes out of your torch matters. If you don’t use enough gas, your weld won’t be protected. If you use too much, you waste gas and can cause turbulence that lets air in.

- Torch Angle: The angle of your welding torch also affects how well the gas shields the weld. Keep the torch pointed so the gas flows over the molten metal.

- Contamination: Make sure your metal and the gas are clean. Dirt or oil on the stainless steel will cause problems.

4. User Experience and Use Cases

What’s it like to weld with different gases, and when do you use them?

- Argon/CO2 Mixes: These are popular for general stainless steel welding. They offer a good balance of shielding and penetration. They are easier to use and give good results for most projects.

- Argon/Oxygen Mixes: These are used for specific situations where a very smooth arc and good wetting (how well the metal spreads) are needed. They can be a bit trickier to master.

- Pure Argon: While good for shielding, pure argon might not give enough heat for thicker stainless steel. It’s often used for very thin materials or when a super clean, shiny finish is the top priority.

Think about what you’re making. Are you building a fancy kitchen appliance? Or maybe fixing a car part? The right gas will help you get the job done right.

Frequently Asked Questions (FAQ)

Q: What is the best gas for MIG welding stainless steel?

A: The most common and often best gas mix is 90% Argon and 10% CO2. Some welders also use mixes with a small amount of Oxygen.

Q: Can I use pure Argon for MIG welding stainless steel?

A: Yes, you can. Pure Argon offers excellent shielding but might not provide enough heat for thicker stainless steel.

Q: What happens if I use too much CO2 in my gas mix?

A: Too much CO2 can make your welds rough, reduce their strength, and affect the stainless steel’s resistance to rust.

Q: How much gas should I use?

A: The ideal gas flow rate depends on your welding machine and the conditions. A good starting point is usually between 20-30 cubic feet per hour (CFH).

Q: Does the gas affect the color of my stainless steel weld?

A: Yes, the gas mix can influence the color of the weld. Certain mixes help achieve a cleaner, brighter finish.

Q: What’s the difference between Argon and CO2 for welding?

A: Argon is a noble gas that provides good shielding. CO2 is more reactive and helps with deeper penetration but can cause more spatter and affect the metal’s properties.

Q: Can I use a gas for steel on stainless steel?

A: It’s not recommended. Gases designed for regular steel often have higher CO2 or Oxygen content that is not suitable for stainless steel and can damage it.

Q: How do I know if my gas flow is correct?

A: You can often hear a steady hiss from your torch. Too much gas can sound like a roar, and too little might be barely audible.

Q: What kind of regulator do I need for my gas cylinder?

A: You need a flowmeter regulator designed for the specific gas you are using. It allows you to control and measure the gas flow rate.

Q: Where can I buy the right gas for MIG welding stainless steel?

A: You can buy welding gases from local welding supply stores or industrial gas suppliers. They can also help you choose the right mix.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.