Ever tried welding stainless steel with TIG and ended up with a messy, discolored weld? You’re not alone. Choosing the right shielding gas for TIG welding stainless steel can feel like navigating a maze. It’s a critical step, and getting it wrong often leads to frustration, rework, and less-than-perfect results. Many welders wrestle with which gas will give them that shiny, clean finish they’re after, without the hassle.

But what if there was a way to cut through the confusion? This post will unlock the secrets to selecting the perfect gas for your stainless steel TIG projects. You’ll learn exactly why certain gases work better than others, what to look for, and how to avoid common pitfalls. By the end, you’ll have the confidence to pick the ideal gas every time, leading to smoother welds and a more professional look for your work.

Our Top 5 Gas For Tig Welding Stainless Steel Recommendations at a Glance

Top 5 Gas For Tig Welding Stainless Steel Detailed Reviews

1. YESWELDER Stainless Steel TIG Welding Rod ER308L 3/32″x16″ 5LB

Rating: 8.8/10

The YESWELDER Stainless Steel TIG Welding Rod ER308L 3/32″x16″ 5LB is a top choice for many welding projects. It’s made for common uses where things need to be tough and resist rust a bit. This rod is also good for very cold temperatures.

What We Like:

- This is the most popular stainless steel rod for general jobs.

- It works well in cold places, even way below freezing.

- Using it with the right gas, like 100% Argon, helps you weld faster and deeper.

- The low carbon in the rod helps prevent rust after welding.

- It’s great for welding many types of stainless steel, like 304 and 308.

- You can use it for many different things, like in factories, for food machines, and even for medical tools.

What Could Be Improved:

- The 5LB pack might be more than some people need for small jobs.

- Finding this specific size might take a little searching at some stores.

This YESWELDER rod gives you reliable welds for many stainless steel projects. It’s a dependable option for both hobbyists and professionals.

2. ARCCAPTAIN Stainless Steel TIG Welding Rod ER308L TIG Filler Rod

Rating: 9.4/10

The ARCCAPTAIN Stainless Steel TIG Welding Rod ER308L TIG Filler Rod is a top-notch choice for welders. This 1/16″ by 16″ rod comes in a convenient 5LB pack. It’s made for TIG welding and is designed to give you great results, especially on thinner materials. If you need reliable stainless steel welding, this rod is worth considering.

What We Like:

- This ER308L rod is low-carbon stainless steel. It fights off corrosion between crystal grains really well.

- It works great for welding in any position.

- The 1/16″ diameter and 16″ length are perfect for many projects.

- You can use 100% Argon or an Argon/Helium mix as shielding gas.

- It’s ideal for welding thin plates.

- You’ll find it used in lots of industries like petrochemicals, pressure vessels, food machinery, and medical equipment.

- Welding with these rods is smooth. The melt depth is good, and there are no annoying splashes.

- The welding channel is nice and even. This means you can weld from one side and get a good look on both sides.

What Could Be Improved:

- For very thick materials, you might need a larger diameter rod.

- While easy to use, mastering TIG welding takes practice for everyone.

This ARCCAPTAIN welding rod offers excellent performance and versatility for stainless steel projects. You can achieve clean, strong welds with ease.

3. YESWELDER Stainless Steel TIG Welding Rod ER308L 1/16″x16″ 5LB

Rating: 8.8/10

The YESWELDER Stainless Steel TIG Welding Rod ER308L is a top choice for many welding jobs. It’s great for general use and can even handle cold temperatures. This rod helps make strong welds that resist rust and corrosion, especially in everyday situations. It’s designed for TIG welding, which is a precise way to join metals.

What We Like:

- Excellent for general stainless steel welding, especially for 304 and 304L types.

- The low carbon content helps prevent rust after welding.

- Works well in various tough places, like where it gets very cold.

- Good for many different jobs, from making food equipment to fixing medical tools.

- You can use pure argon or a mix with helium for better welding results.

What Could Be Improved:

- The 5lb pack might be more than a beginner needs.

- Finding specific technical details for very advanced uses might require more research.

This YESWELDER rod is a reliable option for most stainless steel TIG welding needs. It delivers good results for a wide range of projects.

4. Deer Head Welding kit For Beginners Practice

Rating: 9.5/10

Ready to test your welding skills and create something amazing? This Deer Head Welding Kit is designed for beginners and experienced welders alike, offering a unique challenge. It includes 15 pieces of 201 stainless steel welding coupons, precision-cut and ready for you to transform into a stunning deer head sculpture. Whether you’re practicing TIG, MIG, gas, arc, or stick welding, these coupons provide a fantastic opportunity to hone your craft and unleash your creativity.

What We Like:

- Great for Practice: This kit is perfect for practicing various welding techniques like TIG, MIG, gas, arc, and stick.

- Unleash Creativity: You can build a unique stainless steel deer head, showing off your artistic side and welding ability.

- High-Quality Material: The coupons are made from durable 201 stainless steel and are precision-cut for a good fit.

- Unique Gift Idea: It makes a thoughtful and memorable gift for Father’s Day, or for any art lover or welding enthusiast.

- Challenging Project: It offers a fun and rewarding challenge that helps you improve your welding skills.

What Could Be Improved:

- Beginner Difficulty: While it’s for beginners, creating a detailed deer head might still be a bit challenging for absolute novices without some guidance.

- Limited Design Options: The kit focuses on a deer head; different project options could add more variety.

This kit is an excellent way to improve your welding and create a cool piece of art. It’s a gift that sparks imagination and celebrates craftsmanship.

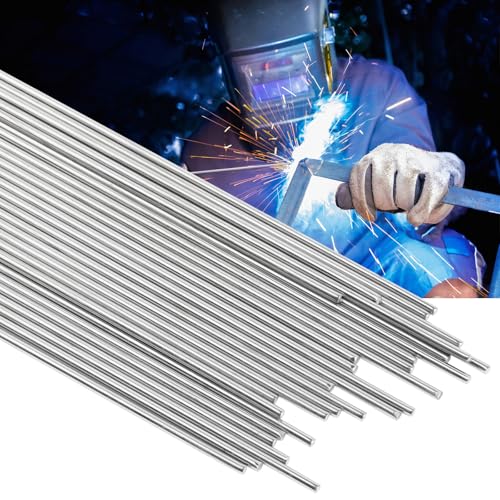

5. Verdanzia 30 Pcs Stainless Steel Tig Welding Rod ER308L

Rating: 8.7/10

Unleash your welding potential with the Verdanzia 30 Pcs Stainless Steel Tig Welding Rod ER308L. These high-quality rods are built for strength and durability, helping you achieve smooth, clean welds with minimal mess. Whether you’re a seasoned pro or just starting out, these rods make welding easier and more effective.

What We Like:

- Made from strong, high-grade stainless steel for tough projects.

- They create smooth welds with very little splatter.

- Reliable performance means you can count on them every time.

- Great for many jobs like construction, machinery, and boat building.

- The 1/16″ x 16″ size is easy to handle and covers your work well.

- They resist rust and high heat, perfect for tough places.

- Easy to start and keep a steady weld, saving you cleanup time.

What Could Be Improved:

- The 30-piece pack might be too much for very small jobs.

The Verdanzia ER308L welding rods offer excellent quality and versatility for a wide range of welding needs. They are a solid choice for anyone looking to improve their welding results.

Choosing the Right Gas for TIG Welding Stainless Steel

TIG welding stainless steel takes skill and the right equipment. One of the most important choices you’ll make is selecting the correct shielding gas. The right gas protects your weld from the air, which can cause problems like contamination and weakness. Let’s dive into how to pick the best gas for your stainless steel TIG welding projects.

Key Features to Look For in Shielding Gas

When you’re shopping for TIG welding gas for stainless steel, keep these features in mind:

- Purity: High purity gas is crucial. Impurities can react with your weld and cause defects. Look for gas with 99.99% or higher purity.

- Type of Gas: Different gases work better for different stainless steel types and welding situations. We’ll cover the main types below.

- Flow Rate: You need enough gas to create a good shield, but not so much that it causes turbulence and pulls in air.

- Cylinder Size and Availability: Consider how much welding you do. Larger cylinders last longer but are heavier. Make sure the gas is easy to get where you are.

Important Materials: Gas Types for Stainless Steel

The most common gases used for TIG welding stainless steel are Argon and its mixtures.

- Pure Argon: This is the go-to gas for most stainless steel TIG welding. It’s inert, meaning it doesn’t react with the metal.

- Pros: Excellent arc stability, clean welds, good penetration.

- Cons: Can sometimes lead to a flatter bead profile.

- Argon/Helium Mixtures: Adding helium to argon can increase heat input. This is helpful for thicker stainless steel or when you need faster travel speeds.

- Pros: Deeper penetration, wider bead, faster welding.

- Cons: Can be more expensive than pure argon, may require higher flow rates.

- Argon/Hydrogen Mixtures: Small amounts of hydrogen can be added to argon for welding stainless steel. Hydrogen helps to deoxidize the weld pool, leading to a brighter, cleaner bead.

- Pros: Brighter, cleaner welds, good for thin stainless steel.

- Cons: Hydrogen can cause porosity (small holes) if the flow rate is too high or if there’s contamination. Not suitable for all stainless steel alloys.

Factors That Improve or Reduce Weld Quality

Several things affect how good your stainless steel TIG welds will be. The shielding gas plays a big role.

- Gas Purity: As mentioned, pure gas makes a better weld.

- Flow Rate: Too little gas leaves your weld exposed to air. Too much gas can disturb the arc and pull in unwanted air. Finding the sweet spot is key.

- Proper Setup: Make sure your TIG torch has the right cup size for the job. A larger cup generally allows for better gas coverage.

- Cleanliness: Always clean your stainless steel thoroughly before welding. Oil, grease, and dirt will contaminate the weld, no matter how good your gas is.

- Welding Technique: Steady hands and consistent movement are vital. The gas helps, but your technique makes the final weld.

User Experience and Use Cases

Many welders find that pure Argon is the easiest to start with for stainless steel. It provides a stable arc and forgiving weld puddle. If you’re welding thinner stainless steel for decorative items or kitchen equipment, pure Argon is usually perfect.

For thicker stainless steel, like in structural applications or exhaust systems, welders might switch to an Argon/Helium mix. This extra heat helps them get through the thicker material faster and with better penetration.

If you’re aiming for that super shiny, mirror-like finish on stainless steel, a small addition of hydrogen to your Argon might be the answer. However, this requires more practice to avoid issues.

Frequently Asked Questions (FAQ)

Q: What is the best gas for TIG welding stainless steel?

A: Pure Argon is the most common and often the best gas for general TIG welding of stainless steel.

Q: Can I use pure Argon for all types of stainless steel?

A: Yes, pure Argon works well for most common stainless steel grades.

Q: When should I use an Argon/Helium mix?

A: Use an Argon/Helium mix when welding thicker stainless steel or when you need more heat and faster travel speeds.

Q: What are the risks of using Argon/Hydrogen?

A: Too much hydrogen or contamination can cause porosity (small holes) in your weld.

Q: How do I know the right gas flow rate?

A: Start with the manufacturer’s recommendation and adjust based on your welding results. You want a steady, protective gas flow without turbulence.

Q: Does the cup size on my TIG torch matter for gas coverage?

A: Yes, a larger cup generally provides better gas coverage for your weld.

Q: How important is cleaning stainless steel before welding?

A: Cleaning is extremely important. Contamination leads to poor welds.

Q: Can I mix gases myself?

A: It’s best to buy pre-mixed gases from a welding supplier. They ensure the correct mixture ratios.

Q: How much does shielding gas cost?

A: The cost varies depending on the gas type, cylinder size, and your location. Argon is generally less expensive than helium mixes.

Q: Where can I buy TIG welding gas for stainless steel?

A: You can buy TIG welding gas from welding supply stores and industrial gas distributors.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.