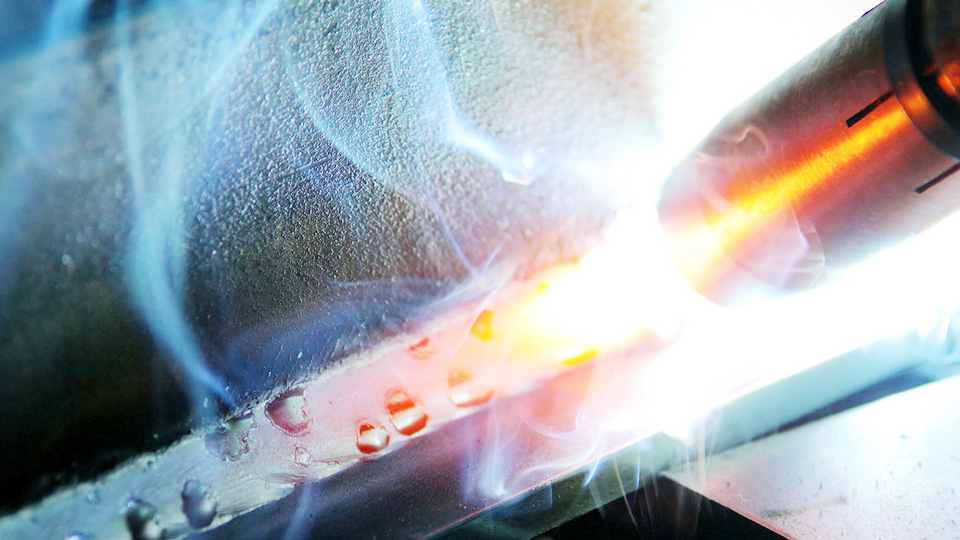

Hot pressure welding is a unique and highly efficient process used in a variety of industries to join metals. This process relies on the combination of heat and pressure to create a solid-state bond between materials without melting them. The application of heat softens the materials, and pressure is used to forge them together at the atomic level.

Diagrams play a crucial role in understanding the intricacies of this process, as they visually represent the steps involved in hot pressure welding, equipment setup, and material behavior during welding.

We will explore the hot pressure welding process in detail, including diagrams that illustrate how the process works, different methods used, and the factors that influence its effectiveness.

Image by weldingofwelders

What is Hot Pressure Welding?

Hot pressure welding is a solid-state welding technique in which heat and pressure are applied to materials to bond them together without melting. This process differs from fusion welding, where materials are melted to create a bond.

In hot pressure welding, materials are heated to a temperature below their melting point and then pressed together under controlled pressure, allowing for atomic bonding between surfaces.

This method is widely used in industries where high-strength joints, minimal thermal distortion, and precision are critical, such as aerospace, automotive, and electrical manufacturing.

Importance of Diagrams in Hot Pressure Welding

Diagrams are essential tools for understanding the hot pressure welding process. They provide a clear visual representation of the key steps, equipment, and material behavior during welding. These diagrams help engineers and technicians visualize the interaction between heat and pressure, how the materials are deformed and bonded, and the role of different components in the welding system.

Diagrams can explain the variations in pressure welding techniques, such as resistance welding, friction welding, and gas pressure welding. They provide a comprehensive view of the equipment setup, how heat is applied, and how materials are handled during the process.

Components of a Hot Pressure Welding Diagram

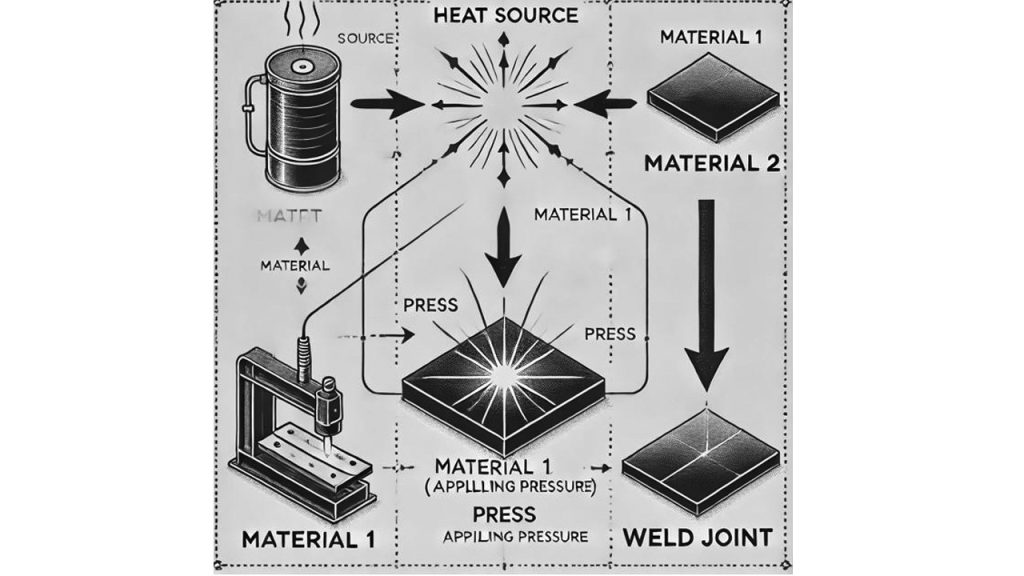

A typical hot pressure welding diagram includes several key components that help explain how the process works. These components include:

- Heat Source: Illustrates the method used to generate heat, whether it is electrical resistance, friction, or gas flame.

- Pressure Application: Shows how pressure is applied to the materials being welded, usually via mechanical presses or clamping devices.

- Materials: Highlights the materials being welded, their initial position, and how they are brought together.

- Weld Joint: Displays the area where the materials are bonded, including any deformation that occurs during the welding process.

These components are essential for understanding how heat and pressure work together to form a strong, durable joint between materials.

Diagram: Basic Hot Pressure Welding Setup

Below is a simple illustration of a basic hot pressure welding setup:

In this diagram:

- The heat source heats both materials to a soft, pliable state.

- Material 1 and Material 2 represent the workpieces to be welded.

- The press applies mechanical pressure, forcing the materials into close contact.

- The weld joint is formed as the atoms of the two materials bond at the contact surface.

This basic setup is common across all hot pressure welding processes, though variations exist depending on the specific type of hot pressure welding being used.

Types of Hot Pressure Welding with Diagrams

There are several types of hot pressure welding processes, each with distinct methods of applying heat and pressure. Below, we explore the most common types of hot pressure welding with accompanying diagrams.

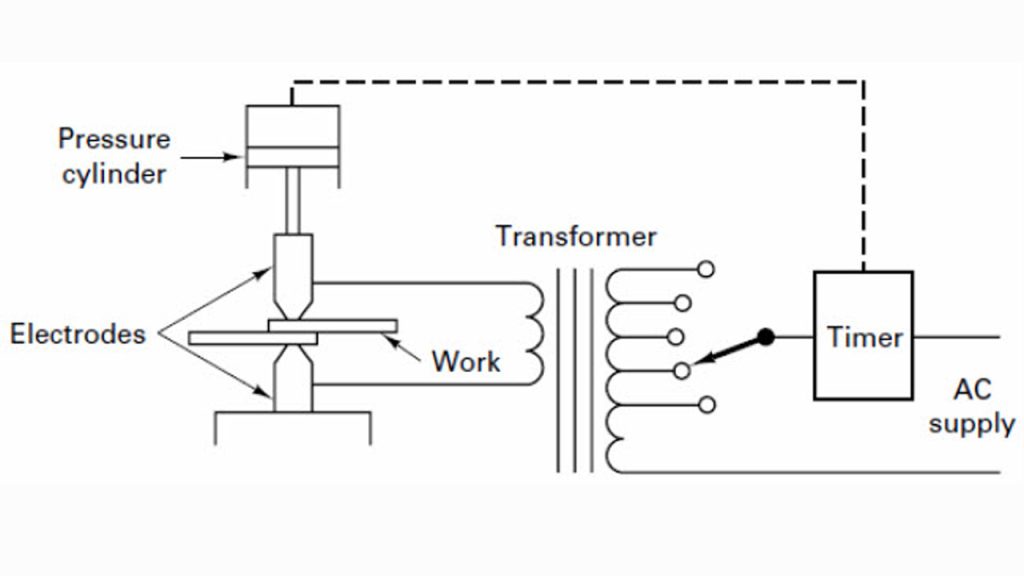

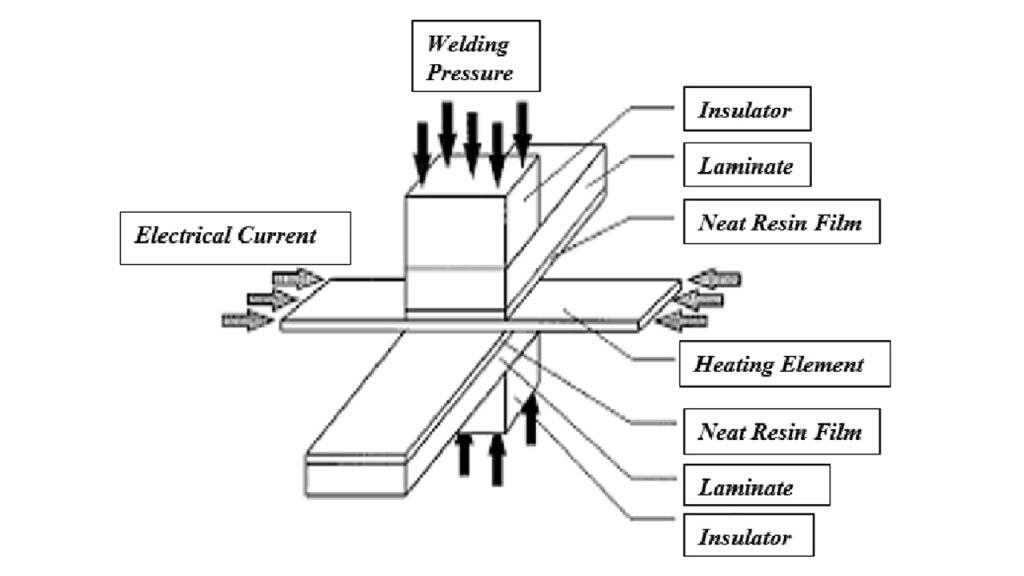

Resistance Welding Diagram

Resistance welding uses an electrical current to generate heat at the contact points of the materials. The heat is produced by the electrical resistance of the materials, and pressure is applied simultaneously to forge the weld.

Resistance Welding Diagram

Image by msvs-dei vlabs ac

In this diagram, the electric current passes through the materials, creating heat due to resistance. The pressing force (mechanical pressure) is applied by the electrodes, ensuring that the materials are bonded once the heat softens them.

Resistance welding is commonly used in industries that require rapid production of thin metal sheets, such as automotive manufacturing.

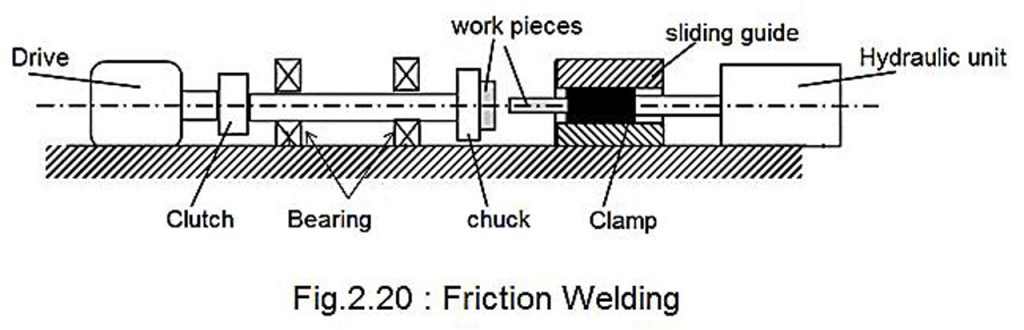

Friction Welding Diagram

Friction welding generates heat through mechanical friction between the materials being welded. One material is rotated or oscillated against the other, generating heat at the interface. Once the materials reach the desired temperature, pressure is applied to bond them.

Friction Welding Diagram

Image by learnmech

Friction welding is often used for joining cylindrical components, such as pipes, rods, or shafts, where creating a strong weld without melting the materials is essential.

Induction Welding Diagram

Induction welding uses electromagnetic fields to heat the materials. An alternating current passes through a coil, generating a magnetic field that induces heat in the materials at the weld joint. Pressure is then applied to create the bond.

Induction Welding Diagram

Image by researchgate

The induction coil generates an electromagnetic field that induces heat in the materials. Once the materials are sufficiently heated, mechanical pressure is applied to forge the weld.

Induction welding is used in applications requiring precision, such as joining pipes or tubes where minimal heat-affected zones are critical.

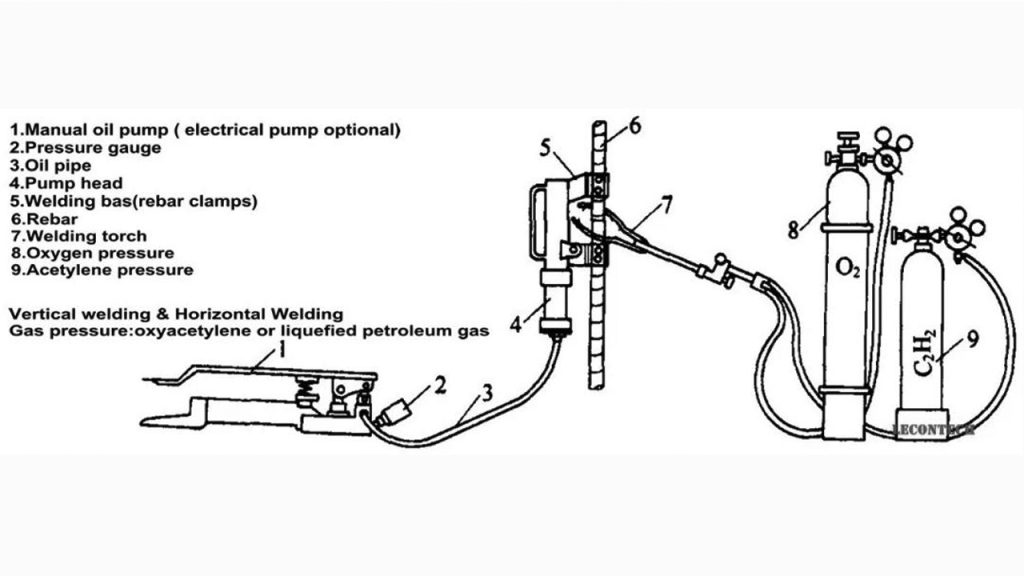

Gas Pressure Welding Diagram

Gas pressure welding involves using a gas flame (often oxygen and acetylene) to heat the materials. Once the materials reach the appropriate temperature, pressure is applied to bond them together.

Gas Pressure Welding Diagram

Image by lecontech

In this diagram, the gas flame heats the materials to a soft state, and pressure is applied by the press to forge the joint.

This method is commonly used for large-scale applications such as rail welding or construction, where strong, durable joints are necessary.

Key Factors Affecting Hot Pressure Welding

Several factors influence the quality and success of the hot pressure welding process. Understanding these factors is crucial for ensuring a strong, reliable weld.

Heat

The amount of heat applied during the welding process must be carefully controlled. If the heat is too low, the materials may not become soft enough to bond. If the heat is too high, the materials may begin to melt or degrade. The ideal temperature will vary depending on the type of materials being welded.

Pressure

Pressure is critical to forming the bond between the materials. Too little pressure may result in a weak joint, while too much pressure could cause deformation or material damage. The pressure must be evenly distributed across the joint to ensure a strong, uniform bond.

Material Type

Not all materials are suitable for hot pressure welding. Metals with similar melting points and thermal properties tend to bond more effectively than dissimilar materials. However, with the right techniques, it is possible to join dissimilar metals.

Surface Preparation

Proper surface preparation is essential for achieving a high-quality weld. Contaminants such as oxides, dirt, or grease on the surface of the materials can interfere with the bonding process. Cleaning and smoothing the surfaces before welding ensures a stronger bond.

Comparison of Hot Pressure Welding Types

| Welding Type | Heat Source | Pressure Application | Materials | Applications |

|---|---|---|---|---|

| Resistance Welding | Electric current | Electrodes press materials | Thin metal sheets | Automotive, sheet metal fabrication |

| Friction Welding | Frictional heat | Rotational or linear pressure | Cylindrical parts | Pipes, rods, aerospace components |

| Induction Welding | Electromagnetic field | Mechanical press | Precision metals | Pipes, tubes, electrical components |

| Gas Pressure Welding | Gas flame (Oxygen/Acetylene) | Mechanical press | Large-scale metal sections | Rail welding, construction, infrastructure |

Applications of Hot Pressure Welding

Hot pressure welding is employed across a wide range of industries due to its ability to create strong, durable joints. Some of the key applications include:

Aerospace

Hot pressure welding is used in the aerospace industry to join lightweight yet strong materials, such as aluminum and titanium, for aircraft and spacecraft components. The process allows for precise control over heat and pressure, resulting in strong joints that can withstand extreme conditions.

Automotive

In the automotive industry, hot pressure welding is used to join chassis components, engine parts, and body panels. The process ensures strong, lightweight bonds that improve vehicle efficiency and safety.

Electrical Engineering

Hot pressure welding is widely used in the electrical engineering sector to join conductive materials like copper and aluminum. The process is essential for producing high-quality connections in wires, cables, and electronic components.

Infrastructure

In the construction and infrastructure sector, hot pressure welding is used to join rail tracks, steel beams, and other structural components.

The process creates strong, durable joints that can withstand heavy loads and harsh environmental conditions.

Conclusion

Hot pressure welding is a versatile and efficient process that combines heat and pressure to create strong, durable joints in metals. Diagrams help illustrate the intricacies of this process, from the heating stage to pressure application and cooling. With various methods such as resistance welding, friction welding, induction welding, and gas pressure welding, this process is suited to a wide range of applications across multiple industries. Understanding the factors that influence the quality of the weld, such as heat, pressure, and material compatibility, is key to ensuring a successful welding operation.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.