Are you wondering how long a welding machine can last? Do you want to know about the common problems that may occur with welding machines and how to troubleshoot them? In this article we will provide you with all the information you need.

Welding machines are vital tools in various industries, but like any other equipment, they have a limited lifespan. Understanding the factors that affect the longevity of a welding machine can help you make informed decisions and ensure its proper maintenance.

We will discuss the average lifespan of a welding machine and the common problems that may arise over time. We will also provide you with troubleshooting tips to help you address these issues effectively. Whether you are a beginner or an experienced welder, this article will give you valuable insights to keep your welding machine running smoothly and efficiently.

Factors that affect the lifespan of a welding machine

The lifespan of a welding machine can vary depending on several factors. Here are some key factors that can affect how long your welding machine will last:

Quality of the machine

The quality of the welding machine plays a significant role in its lifespan. High-quality welding machines are built to last longer and can withstand continuous use. Investing in a reputable brand and choosing a machine made with durable materials can ensure longevity.

Frequency of use

The more frequently you use your welding machine, the shorter its lifespan may be. Continuous use puts strain on the machine’s components, leading to wear and tear. If you use your machine for heavy-duty projects or in demanding environments, it may require more frequent maintenance and repairs.

Maintenance and care

Proper maintenance and care significantly contribute to the lifespan of a welding machine. Regularly cleaning the machine, inspecting for any damage, and lubricating the moving parts can help extend its lifespan. Additionally, following the manufacturer’s guidelines for maintenance and servicing can prevent premature breakdowns.

Operating conditions

The operating conditions in which the welding machine is used can affect its lifespan. Factors such as temperature, humidity, dust, and exposure to harsh chemicals or elements can impact the machine’s performance and longevity. It’s essential to assess the environment in which the machine will be used and take appropriate measures to protect it.

Power supply

The quality and stability of the power supply can impact the lifespan of a welding machine. Fluctuations in voltage or power surges can damage the machine’s electronic components. Using a surge protector or stabilizer can help safeguard the machine from electrical issues and prolong its lifespan.

While these factors can influence the lifespan of a welding machine, proper maintenance and care can go a long way in ensuring its longevity.

Common problems faced by welding machines

Welding machines, like any other equipment, can experience various problems over time. Here are some common issues you may encounter with your welding machine:

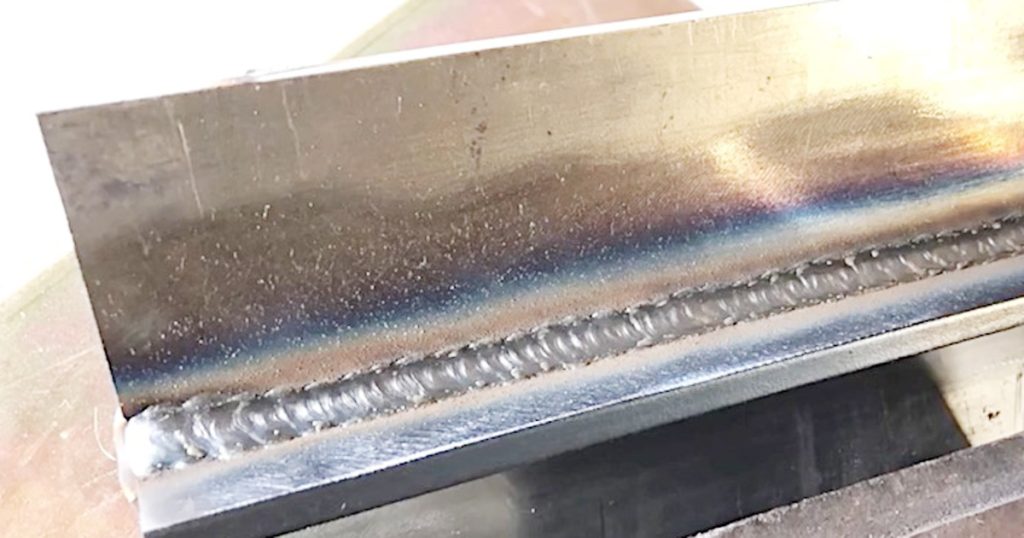

Poor weld quality

One of the most common problems faced by welders is poor weld quality. This can include issues such as incomplete penetration, porosity, or cracks in the welded joint. Poor weld quality can be caused by factors like improper electrode selection, incorrect welding parameters, or inadequate preparation of the base material. Understanding the root cause of the issue is essential to troubleshoot and resolve it effectively.

Overheating

Overheating is another common problem that can occur with welding machines. Continuous use or operating the machine at high amperage levels can cause it to overheat. Overheating can lead to damage to the machine’s internal components and result in reduced performance or even complete breakdown. Proper cooling and ventilation of the machine, as well as avoiding excessive use, can help prevent overheating issues.

Electrical problems

Electrical problems can manifest in various ways, such as flickering lights, tripped breakers, or sudden loss of power. These issues can be caused by loose connections, faulty wiring, or problems with the power supply. It’s important to address electrical problems promptly to prevent any safety hazards and ensure the proper functioning of the machine.

Gas leaks

Gas leaks can occur in welding machines that utilize gas shielding for certain welding processes. These leaks can lead to poor weld quality, increased gas consumption, or even pose a safety risk. Regularly inspecting the gas lines and connections, as well as using appropriate gas flow regulators, can help prevent gas leak issues.

Wire feeding problems

For welding machines that use wire electrodes, wire feeding problems can be a common occurrence. Issues like wire jams, inconsistent wire feeding, or improper wire tension can affect the weld quality and overall performance of the machine. Properly maintaining the wire feeding mechanism and ensuring the correct wire type and size are used can help mitigate these problems.

Image by gizmoplans

Troubleshooting tips for welding machine issues

When faced with welding machine problems, it’s important to troubleshoot and address the issues promptly to minimize downtime and ensure optimal performance. Here are some troubleshooting tips for common welding machine issues:

Poor weld quality

If you are experiencing poor weld quality, start by checking the welding parameters such as voltage, amperage, and wire speed. Ensure that they are set correctly for the type and thickness of the material being welded. Additionally, inspect the electrode or filler wire to ensure it is the appropriate type and size. Proper cleaning of the base material and using the right shielding gas can also improve weld quality.

Overheating

To prevent overheating, make sure the welding machine is adequately cooled and ventilated. Clean any dust or debris that may have accumulated on the machine’s cooling fans or vents. Avoid running the machine at maximum amperage levels for extended periods and take breaks between welding sessions to allow the machine to cool down.

Electrical problems

If you are experiencing electrical issues, start by checking the power supply and connections. Ensure that the power cord is securely plugged in and that there are no loose or damaged wires. If the problem persists, consider consulting a qualified electrician to inspect the electrical wiring and connections.

Gas leaks

To address gas leaks, carefully inspect the gas lines and connections for any signs of damage or leakage. Tighten any loose connections and replace any damaged or worn-out parts. Conduct a leak test by applying a soapy water solution to the connections and observing for any bubbles that indicate gas leakage.

Wire feeding problems

If you are encountering wire feeding problems, check the wire feeding mechanism for any obstructions or jams. Clean the wire feed rollers and ensure that they are properly aligned and tensioned. Verify that the wire spool is positioned correctly and that the wire is feeding smoothly without any kinks or tangles.

Troubleshooting welding machine issues requires a systematic approach and attention to detail. If you are unsure or unable to resolve the problem on your own, it’s advisable to seek assistance from a qualified technician or contact the manufacturer for support.

Regular maintenance for extending the lifespan of a welding machine

Regular maintenance is crucial for extending the lifespan of your welding machine and ensuring its optimal performance. Here are some maintenance practices to incorporate into your routine:

Cleaning

Regularly clean the welding machine to remove dust, debris, and spatter. Use a soft brush or compressed air to clean hard-to-reach areas. Avoid using abrasive materials or excessive force that can damage the machine’s surfaces.

Inspection

Inspect the machine for any signs of wear, damage, or loose connections. Check the cables, hoses, and electrical components for any fraying, cracks, or exposed wires. Ensure that all safety features, such as the ground clamp and electrode holder, are in proper working condition.

Lubrication

Lubricate the moving parts of the welding machine as recommended by the manufacturer. This includes the wire feed mechanism, hinges, and other mechanical components. Use the appropriate lubricant and apply it sparingly to prevent excessive buildup or contamination.

Electrode or wire replacement

Regularly inspect the electrodes or wire feed spool for signs of wear or damage. Replace them as needed to ensure consistent and reliable performance. Using worn-out electrodes or wires can result in poor weld quality and increase the strain on the machine.

Calibration

Periodically calibrate the welding machine to ensure accurate voltage, amperage, and wire speed settings. This can help maintain consistent weld quality and prevent potential issues caused by incorrect parameters.

By following these maintenance practices, you can significantly extend the lifespan of your welding machine and reduce the likelihood of unexpected breakdowns or performance issues.

Image by IndiaMART

Signs that indicate it’s time to replace your welding machine

While proper maintenance can help prolong the lifespan of a welding machine, there comes a time when replacement becomes necessary. Here are some signs that indicate it’s time to consider replacing your welding machine:

Frequent breakdowns

If your welding machine is experiencing frequent breakdowns, even after proper maintenance and repairs, it may be a sign that it has reached the end of its lifespan. Constantly repairing an old machine can become costly and inefficient in the long run.

Obsolete technology

As technology advances, new welding machines with improved features and capabilities are introduced to the market. If your current machine lacks the necessary features or is no longer compatible with modern welding techniques, it may be time to upgrade to a new model.

Inconsistent performance

If your welding machine is consistently delivering poor weld quality or has unreliable performance, it may be a sign of internal wear or damage. In such cases, investing in a new machine can ensure consistent and high-quality welds.

Lack of spare parts

Over time, manufacturers may discontinue the production of certain welding machine models, making it difficult to find spare parts. If you are unable to source the necessary parts for repairs, it may be a sign that it’s time to consider replacing the machine.

Safety concerns

If your welding machine poses safety risks due to outdated safety features or compromised structural integrity, it’s imperative to prioritize safety and replace the machine promptly. Safety should always be the top priority when working with welding equipment.

When considering replacing your welding machine, assess your specific needs, budget, and the requirements of your welding projects. Research different models, consult with experts, and choose a machine that best suits your requirements for long-term productivity and performance.

Different types of welding machines and their average lifespan

Welding machines come in various types, each designed for specific welding processes or applications. Here are some common types of welding machines and their average lifespan:

Stick welding machines

Stick welding machines, also known as shielded metal arc welding (SMAW) machines, are versatile and widely used. On average, a well-maintained stick welding machine can last between 10 to 15 years. However, factors such as frequency of use and operating conditions can affect its lifespan.

MIG welding machines

MIG welding machines, or metal inert gas welding machines, are popular for their ease of use and versatility. With proper maintenance, a MIG welding machine can last between 7 to 12 years. Regularly replacing consumables such as contact tips, nozzles, and liners can help prolong its lifespan.

TIG welding machines

TIG welding machines, or tungsten inert gas welding machines, are commonly used for precision welding. These machines are known for their durability and longevity. With proper care and maintenance, a TIG welding machine can last between 15 to 20 years or even longer.

Plasma cutting machines

Plasma cutting machines are used for cutting through various metals and alloys. The average lifespan of a plasma cutting machine is around 8 to 12 years. Regularly replacing consumables such as electrodes, nozzles, and shields can help maintain its cutting performance.

It’s important to note that these are average lifespans and can vary depending on the factors mentioned earlier. Proper maintenance and care are essential for maximizing the lifespan of any welding machine, regardless of its type.

Image by antbuildz

Choosing the right welding machine for your needs

When selecting a welding machine, it’s crucial to consider your specific welding needs and requirements. Here are some factors to consider when choosing the right welding machine:

Welding process

Determine the welding process that best suits your applications. Consider factors such as the type of materials you will be welding, the thickness of the materials, and the desired weld quality. Different welding processes have varying equipment requirements, so choose a machine that supports your preferred process.

Power requirements

Assess the power supply available in your workspace and ensure that the welding machine you choose is compatible with it. Consider factors such as voltage, amperage, and the type of power source (e.g., single-phase or three-phase).

Portability

If you require mobility or need to transport the welding machine to different job sites, consider the weight, size, and portability features of the machine. Portable welding machines are designed for easy transportation, while larger machines are typically more suitable for stationary workshops.

Budget

Determine your budget and research the available options within your price range. Consider the long-term value and expected lifespan of the machine rather than solely focusing on the initial cost. Investing in a higher-quality machine may result in better performance and longevity.

Brand reputation

Research different brands and their reputation in the welding industry. Look for brands known for their reliability, customer support, and availability of spare parts. Choosing a reputable brand can provide peace of mind and ensure access to reliable technical support if needed.

Consulting with experienced welders or seeking advice from welding equipment suppliers can also help in choosing the right welding machine for your specific needs.

Cost considerations when purchasing a welding machine

When purchasing a welding machine, it’s important to consider both the initial cost and the long-term costs associated with owning and maintaining the machine. Here are some cost considerations to keep in mind:

Initial cost

The initial cost of a welding machine can vary significantly depending on the type, brand, and features. Set a budget and research different options within your price range. Remember that a higher initial investment in a quality machine can result in better performance and longevity.

Consumables

Consumables such as electrodes, wire, shielding gas, and other welding accessories are ongoing costs associated with owning a welding machine. Consider the frequency of consumable replacement and their prices when assessing the long-term costs of operating the machine.

Maintenance and repairs

Regular maintenance and occasional repairs are necessary to keep a welding machine running smoothly.

Conclusion

Understanding the factors that affect the lifespan of a welding machine is crucial for making informed decisions and ensuring proper maintenance. Factors such as the quality of the machine, frequency of use, maintenance and care, operating conditions, and power supply can all impact how long a welding machine will last. By investing in a high-quality machine, practicing regular maintenance and care, and protecting the machine from harsh operating conditions and electrical issues, its lifespan can be extended.

Being aware of common problems faced by welding machines, such as poor weld quality, overheating, electrical problems, gas leaks, and wire feeding issues, allows for prompt troubleshooting and resolution.

By following the provided troubleshooting tips, welders can address these issues effectively, minimize downtime, and ensure optimal performance. Overall, proper maintenance, care, and troubleshooting are key to keeping a welding machine running smoothly and efficiently for an extended period.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.